Novel energy-saving door leaf and preparation method thereof

A door leaf, a new type of technology, applied in the direction of door leaves, ceramic products, and other household appliances, can solve the problems of insufficient heat insulation, poor heat preservation performance, and endangering the life safety of the affected people, and achieve good heat resistance and impact resistance , Excellent sound insulation and heat insulation performance, overcome the effect of easy cracking when heated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

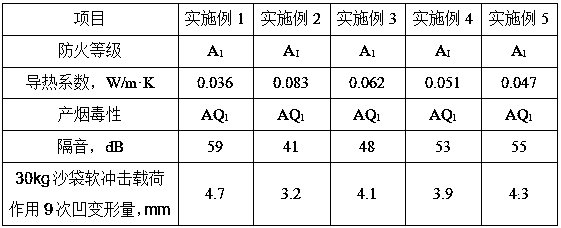

Embodiment 1

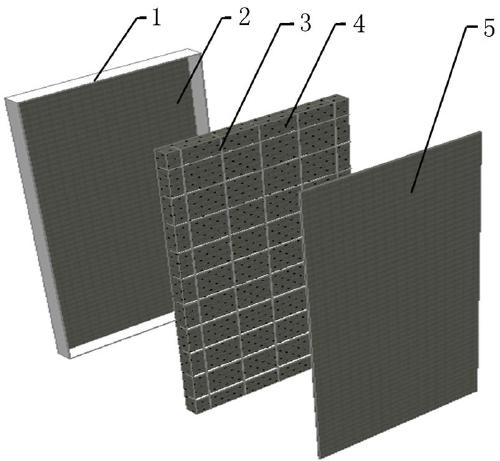

[0031] The novel energy-saving door leaf of present embodiment, by density is 0.9g / cm 3 , Foam concrete with a thickness of 8mm is used as the upper body and the lower body of the shell, galvanized steel plate with a thickness of 2.5mm is used as the side of the shell, grid-shaped light steel is used as the skeleton, and the grid grooves of the light steel skeleton and the door leaf are filled The density in the void of other parts is 0.19g / cm 3 Composed of thermal insulation and fireproof mortar.

[0032] Foamed concrete slurry is made by mixing foamed concrete raw materials and water, and the amount of water added is 51% of the total weight of foamed concrete raw materials; the composition of foamed concrete raw materials includes: ordinary portland cement 47.5%, calcium silicate 15% cement, 6% secondary fly ash, 5% waste building concrete particles, 12% glass fiber, 5% gypsum, 0.6% vegetable protein foaming agent, 0.5% fatty alcohol ether sulfate, α-alkene sulfonic acid S...

Embodiment 2

[0041] The novel energy-saving door leaf of present embodiment is 2.6g / cm by density 3 1. Foamed concrete with a thickness of 6mm is used as the upper body and the lower body of the shell, aluminum alloy with a thickness of 0.8mm is used as the side of the shell, grid-like light steel is used as the skeleton, and the grid grooves filled in the light steel skeleton and other parts of the door leaf Part of the void density is 0.25g / cm 3 Composed of thermal insulation and fireproof mortar.

[0042] Foamed concrete slurry is made by mixing foamed concrete raw materials and water, and the amount of water added is 23% of the total weight of foamed concrete raw materials; the composition of foamed concrete raw materials includes: ordinary portland cement 54%, calcium silicate Cement 12%, primary fly ash 4%, secondary fly ash 7%, tertiary fly ash 3%, waste building concrete particles 9%, glass fiber 5.5%, gypsum 1.5%, α-olefin sulfonic acid 0.2% salt, 0.7% sodium carbonate, 1.3% anh...

Embodiment 3

[0051] The novel energy-saving door leaf of present embodiment, by density is 2.7g / cm 3 1. Foam concrete with a thickness of 3mm is used as the upper body and lower body of the shell, copper with a thickness of 1.5mm is used as the side of the shell, grid-like light steel is used as the skeleton, and the grid grooves of the light steel skeleton and other parts of the door leaf are filled. The density in the void is 0.23g / cm 3 Composed of thermal insulation and fireproof mortar.

[0052] Foam concrete slurry is made by mixing foam concrete raw materials and water, and the amount of water added is 20% of the total weight of foam concrete raw materials; the composition of foam concrete raw materials includes: ordinary portland cement 55%, calcium silicate Cement 12%, sulfoaluminate cement 2%, slag cement 3%, primary fly ash 4%, secondary fly ash 5%, tertiary fly ash 3%, waste building concrete particles 8%, glass fiber 4%, gypsum 1%, animal protein foaming agent 0.2%, sodium ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com