Surface modification method of high-nickel ternary material lithium nickel cobalt manganate

A high-nickel ternary material, nickel-cobalt-lithium manganate technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problem that it is not suitable for industrial mass production, the electrochemical performance is not ideal, and the preparation method is complicated. and other problems, to achieve the effect of improving cycle stability and safety, good rate performance and cycle stability, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) According to AlPO 4 The coating amount is 1wt%, and the stoichiometric ratio of Al(NO3)3·9H2O and NH4H2PO4 is weighed and dissolved in 10ml and 20ml of absolute ethanol respectively, and then the two are mixed and stirred for 3 hours.

[0026] (2) Weigh 10g of LiNi0.6Co0.2Mn0.2O2 as the main material and slowly add it into the above mixed liquid, and keep stirring until the ethanol is completely volatilized;

[0027] (3) The obtained product was dried at 80° C. for 12 hours; finally, in an air atmosphere, it was kept at 700° C. in a tube furnace for 6 hours to obtain a high-nickel ternary nickel-cobalt-manganese with a 1wt% aluminum phosphate coating on the surface Cathode material LiNi0.6Co0.2Mn0.2O2.

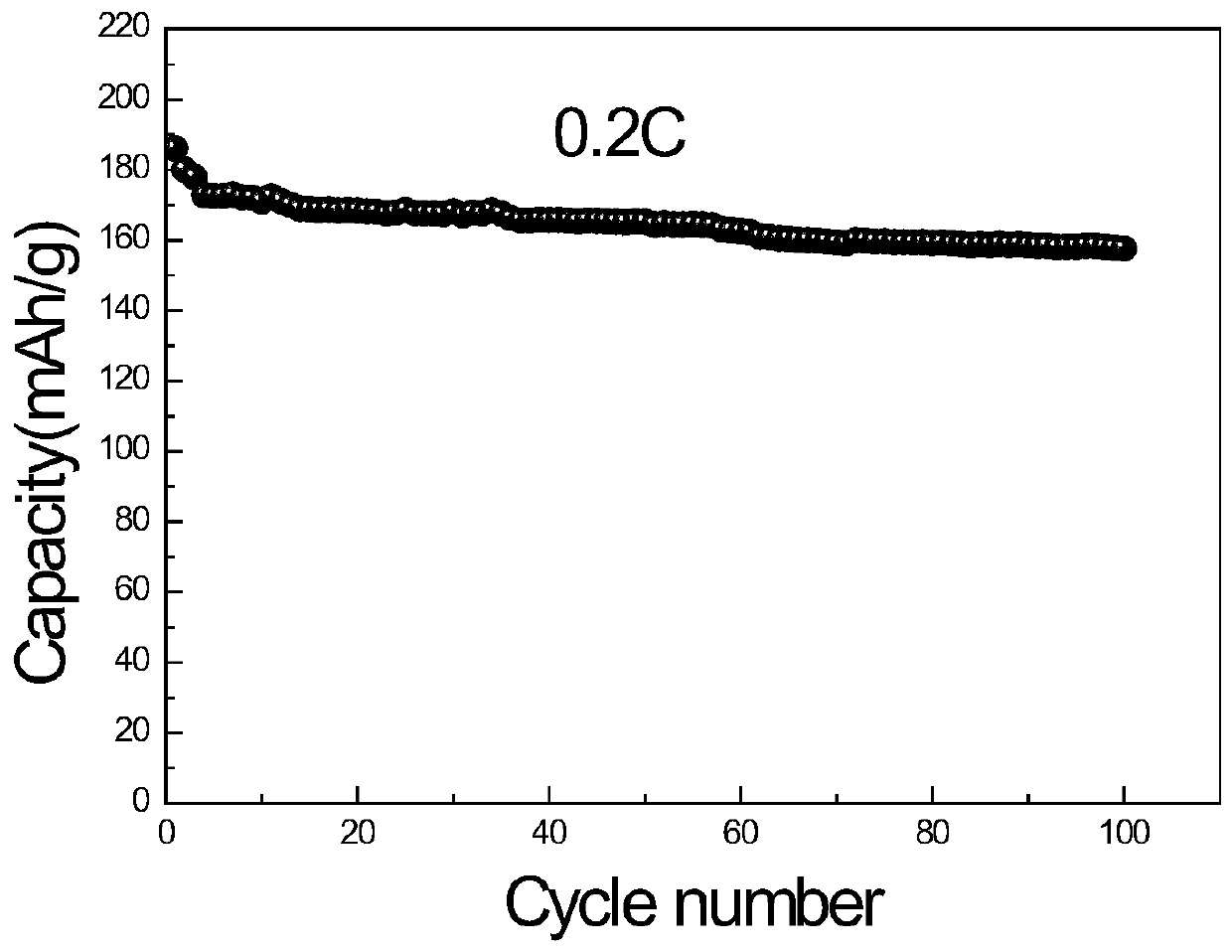

[0028] The material obtained by the above method was scanned by a scanning electron microscope (SEM); the material was assembled into a battery as a positive electrode material of a lithium-ion battery for electrochemical performance testing, and the obtained test ...

Embodiment 2

[0032] (1) According to Li 3 PO 4 The coating amount is 0.5wt%, and the NH4H2PO4 of stoichiometric ratio is weighed and dissolved in 20ml of absolute ethanol, and stirred for 3 hours (the source of coated lithium comes from the surface residual lithium LiOH, LiNi0.6Co0.2Mn0.2O2 of high-nickel material LiNi0.6Co0.2Mn0.2O2 2 CO 3 ).

[0033] (2) Weigh 10g of LiNi0.6Co0.2Mn0.2O2 as the main material and slowly add it into the above mixed liquid, and keep stirring until the ethanol is completely volatilized;

[0034] (3) The obtained product was dried at 80°C for 12 hours, and finally kept at 600°C in a tube furnace for 6 hours in an air atmosphere to obtain a high-nickel ternary nickel-cobalt with a 0.5wt% lithium phosphate coating on the surface Manganese cathode material LiNi0.6Co0.2Mn0.2O2.

[0035] The material obtained by the above method was scanned by a scanning electron microscope (SEM); the material was assembled into a battery as a positive electrode material of a l...

Embodiment 3

[0037] (1) According to Co 3 (PO 4 ) 2 The coating amount is 1wt%, and the stoichiometric ratio of Co(NO3 ) 2 ·6H 2 O and NH4H2PO4 were dissolved in 10ml and 20ml of absolute ethanol respectively, and then the two were mixed and stirred for 3 hours.

[0038] (2) Weigh 10g of LiNi0.6Co0.2Mn0.2O2 as the main material and slowly add it into the above mixed liquid, and keep stirring until the ethanol is completely volatilized;

[0039] (3) The obtained product was dried at 80° C. for 12 hours, and finally kept at 750° C. in a tube furnace for 5 hours in an air atmosphere to obtain a high-nickel ternary nickel-cobalt-manganese with a 1wt% cobalt phosphate coating layer on the surface Cathode material LiNi0.6Co0.2Mn0.2O2.

[0040] The material obtained by the above method was scanned by a scanning electron microscope (SEM); the material was assembled into a battery as a positive electrode material of a lithium ion battery for electrochemical performance testing, and the test co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com