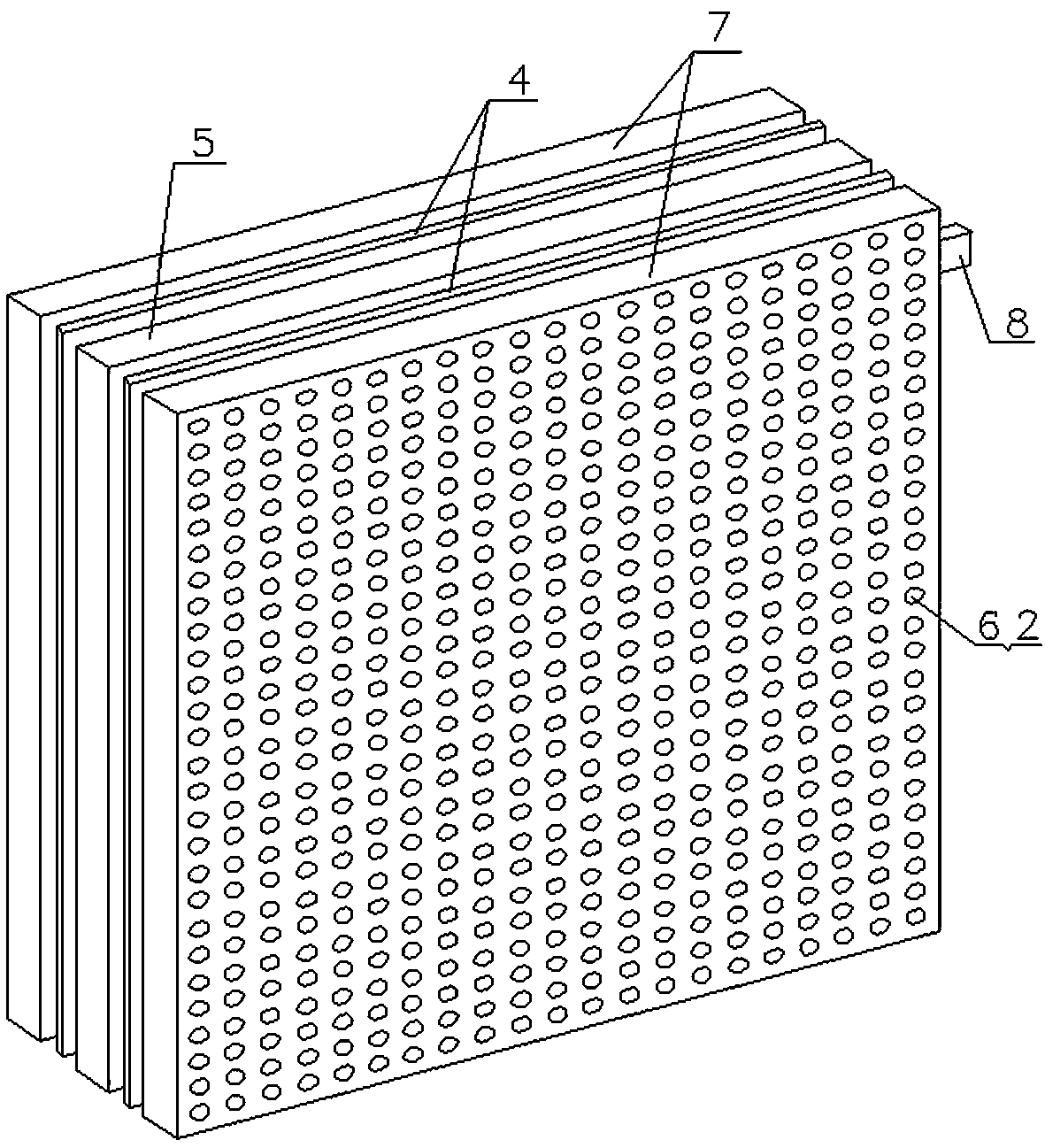

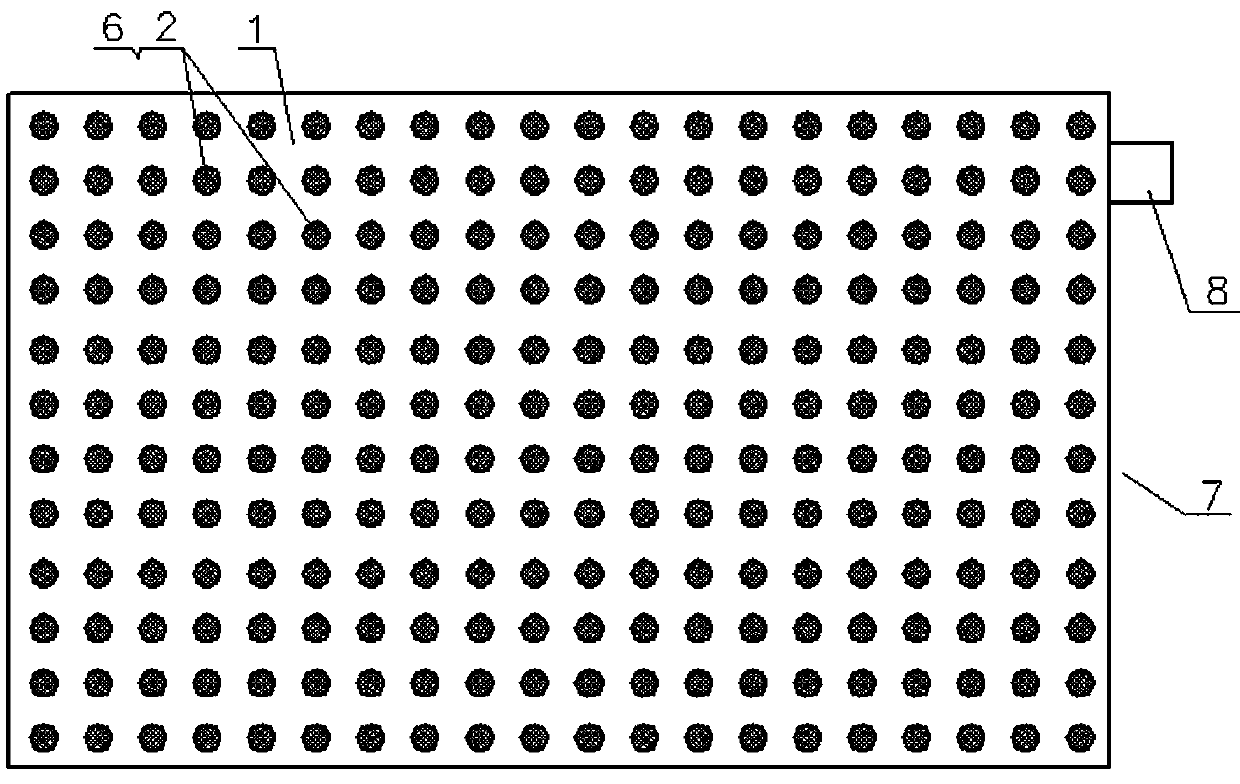

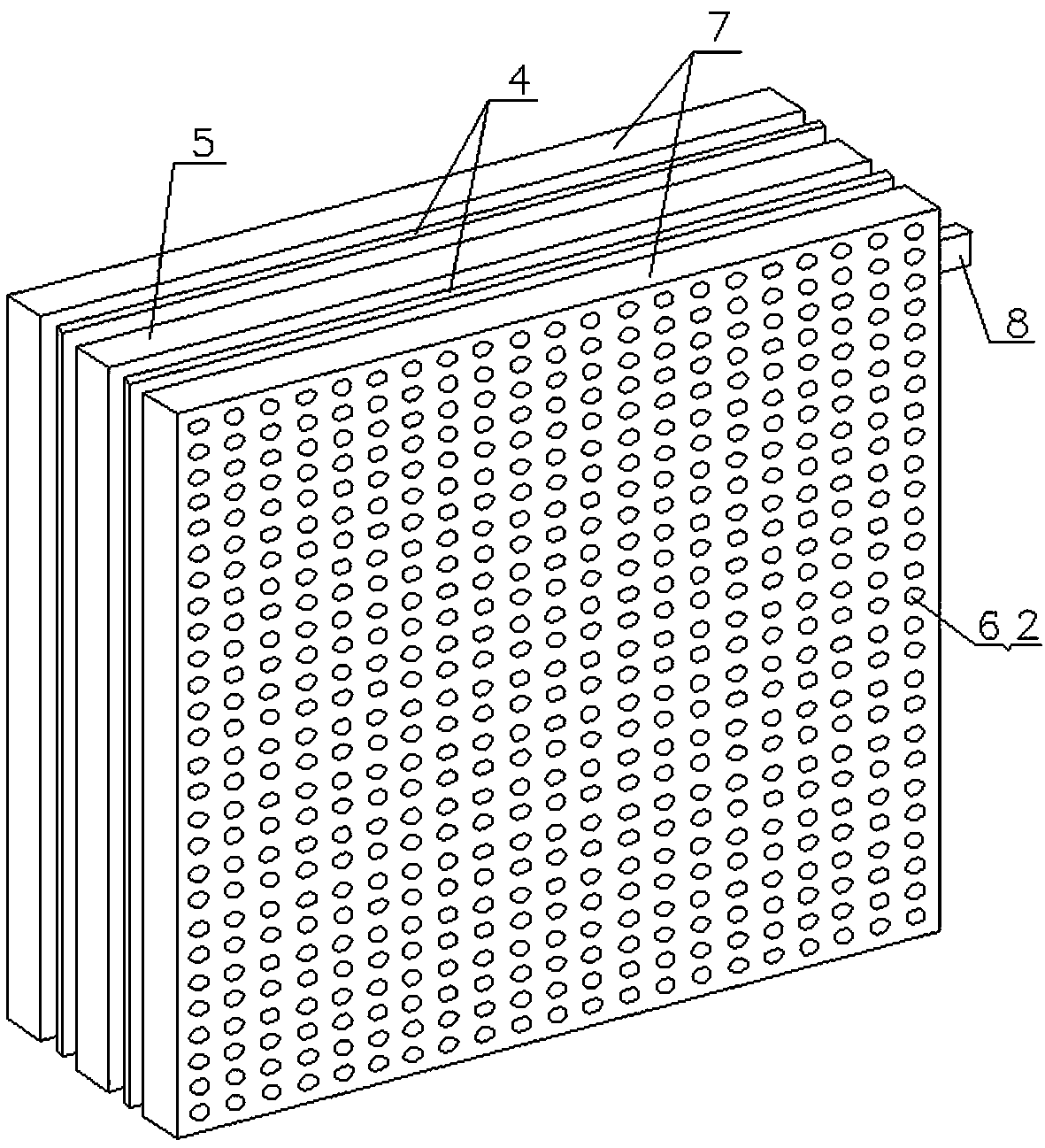

High-purity copper-based battery based on plant activated carbon and preparation method thereof

A plant activated carbon, high-purity copper technology, applied in active material electrodes, secondary battery manufacturing, electrode manufacturing, etc., can solve the problems of poor battery cycle performance, limited battery power, easy to fall off, etc., to improve the charge/discharge performance. , the effect of increasing the diffusion coefficient and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] S100: Shorten wheat straw and carbonize it at 300°C for 13 minutes, then carbonize it at 800°C for 20 minutes and cool it out of the oven to obtain wheat straw activated carbon; carbonize the wood residue at 500°C for 10 minutes, then carbonize it at 1000°C for 15 minutes The wood residue activated carbon is obtained by cooling in 1 minute, and the wheat straw activated carbon and the wood residue activated carbon are mixed according to the mass ratio of 1:3, and then crushed to a fineness of 1600 mesh, and the carbonized iodine value is 800, the ash content is 11 and the water content is <3. Plant activated carbon filler.

[0040] S200: Fully stir and mix the above plant activated carbon filler and the solid electrolyte at a ratio of 1:5 to obtain a mixed filler.

[0041] S300: Soak the high-purity copper mesh in 5% FeCl3 and HCl dilute solution for 30 minutes, and then place it in N 2 The annealing treatment was performed under atmosphere for 30 minutes, and the anne...

Embodiment 2

[0046] S100: Carbonize corncobs at 400°C for 15 minutes, then carbonize them at 1200°C for 15 minutes and cool them out of the oven to obtain corncob activated carbon; cut bamboo into sections and carbonize them at 450°C for 15 minutes, then carbonize them at 1200°C for 25 minutes Take it out of the oven and cool to get bamboo activated carbon, mix the corncob activated carbon and bamboo activated carbon in a mass ratio of 1:1, and then crush it to a fineness of 1200 mesh to obtain plant activated carbon with a carbonized iodine value of 1500, an ash content of 6 and a moisture content of <3 filler.

[0047] S200: Fully stir and mix the above-mentioned plant activated carbon filler and the solid electrolyte at a ratio of 1:1 to obtain a mixed filler.

[0048] S300: Put the high-purity copper mesh in 5% FeCl 3 and HCl dilute solution for 30 minutes, then placed in N 2 / He was annealed in a 1:1 mixed atmosphere for 50 minutes, and the annealing temperature was 800°C.

[0049]...

Embodiment 3

[0053] S100: Carbonize corncobs at 400°C for 15 minutes, then carbonize them at 1200°C for 15 minutes and cool them out of the oven to obtain corncob activated carbon; carbonize corn stalks at 350°C for 10 minutes, then carbonize them at 1000°C for 17 minutes and leave them out of the oven for cooling Obtain corncob activated carbon; carbonize bamboo at 450°C for 15 minutes after cutting into sections, and then carbonize at 1200°C for 25 minutes to obtain bamboo activated carbon. : The mass ratio of 1:2 is mixed and crushed to a fineness of 2000 mesh to obtain a plant activated carbon filler with an iodine carbide value of 1000, an ash content of 16 and a moisture content of <3.

[0054] S200: Fully stir and mix the above-mentioned plant activated carbon filler and the solid electrolyte at a ratio of 1:3 to obtain a mixed filler.

[0055] S300: Put the high-purity copper mesh in 5% FeCl 3 and HCl dilute solution for 10 minutes, then placed in Ar / H 2 The annealing treatment w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com