Irradiation-resisting FCC structure high-entropy alloy and preparing method thereof

A high-entropy alloy and radiation-resistant technology, applied in the field of alloys, can solve problems such as poor mechanical properties of irradiation, and achieve the effects of improving high-temperature performance, improving corrosion resistance, and excellent mechanical and radiation resistance properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment discloses a Fe-Co-Ni-V-Mo-Ti-Cr radiation-resistant FCC structure high-entropy alloy, whose general formula is FeCoNiVMoTi 0.1 Cr 0.1 .

[0027] FeCoNiVMoTi 0.1 Cr 0.1 The specific preparation method is as follows: the raw materials Fe, Co, Ni, V, Mo, Ti and Cr are stacked according to the molar ratio shown in the general formula, and the elements of Fe, Co, Ni, V, Mo, Ti and Cr are all selected with a purity of 99.5wt % more than industrial grade pure raw materials. Then vacuum arc melting or vacuum magnetic levitation melting is adopted. When melting the alloy, the Ti, Fe, Co and Ni are placed at the bottom, and the Mo, Cr and V are placed at the top, and the vacuum is evacuated to 5×10 -3 Pa, then backflush argon to 0.05MPa. Each alloy ingot is melted at least five times during arc melting to ensure uniform composition.

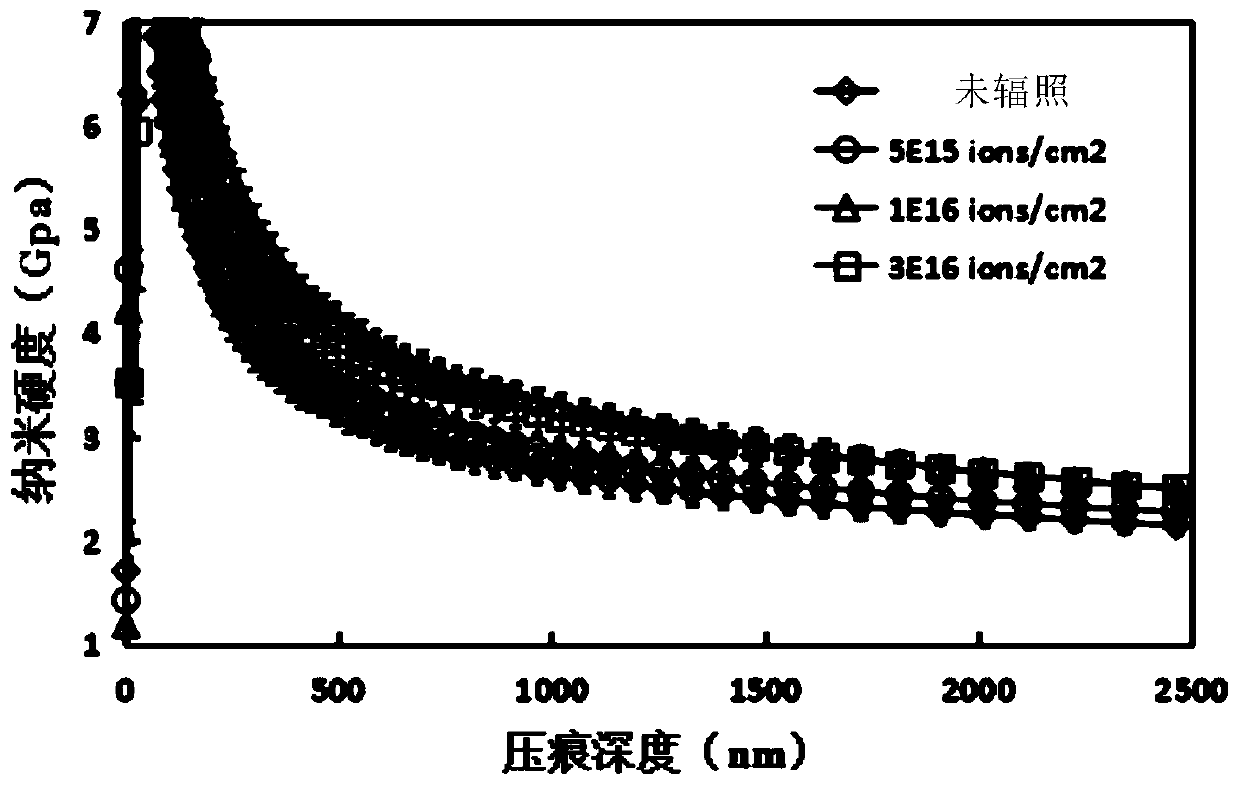

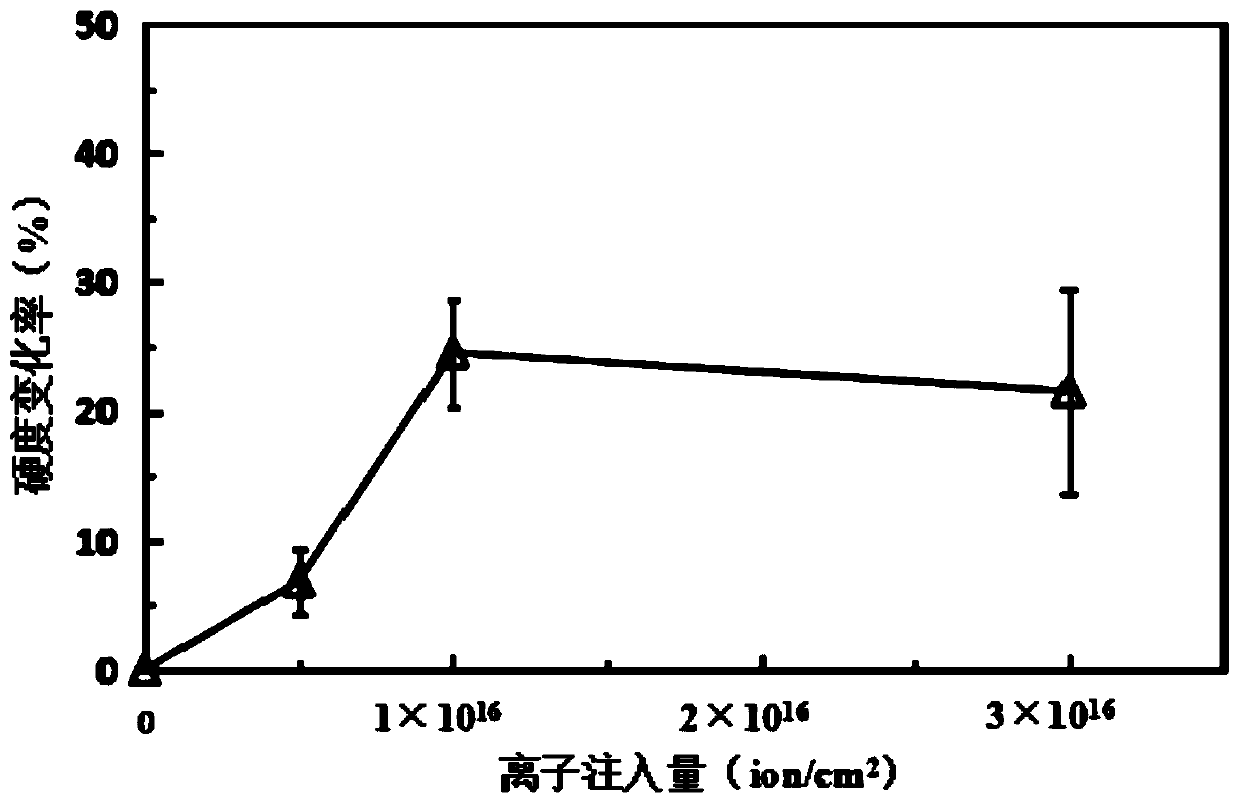

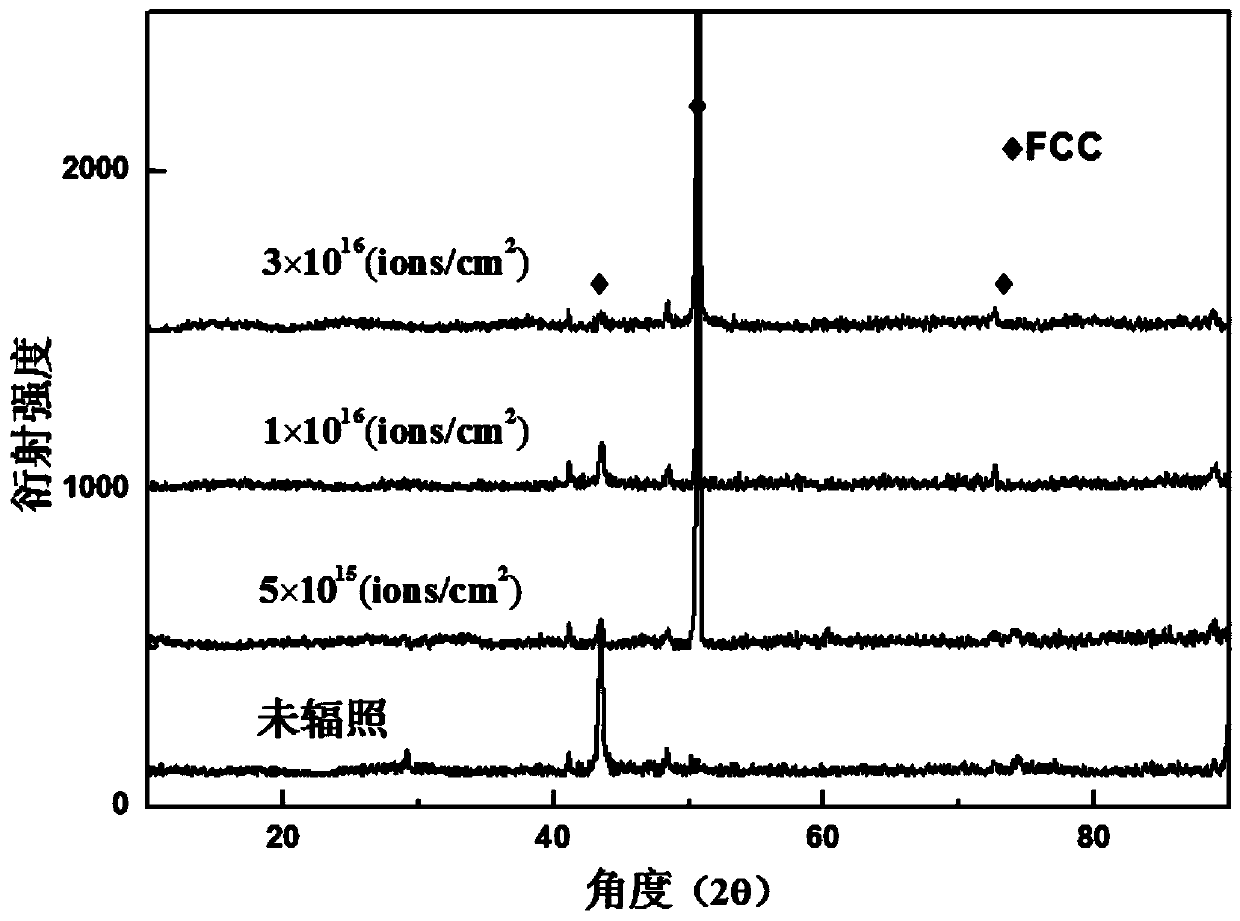

[0028] figure 1 It is the relationship between the average nano-indentation hardness and the indentation depth before and af...

Embodiment 2

[0032] This embodiment discloses a high-entropy alloy with a radiation-resistant FCC structure, whose general formula is FeCoNiVMoTi 0.15 Cr 0.15 . The preparation method of the radiation-resistant high-entropy alloy in this example is the same as that in Example 1.

[0033] After testing this embodiment FeCoNiVMoTi 0.15Cr 0.15 and Example 1 FeCoNiVMoTi 0.1 Cr 0.1 It also has excellent mechanical properties and radiation resistance, and can be widely used as fuel cladding materials in nuclear power plant reactors or key metal parts of nuclear power plants.

[0034] The present invention is not limited to the description of the radiation-resistant high-entropy alloy described in any one of Examples 1-2, wherein changes in x and y and changes in the preparation method are within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com