High-performance glass fiber coating and preparation method thereof

A glass fiber coating, high-performance technology, applied in the field of coating and coating, coating, can solve the problems of poor alkali resistance, poor storage stability, etc., and achieve the effect of improving alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

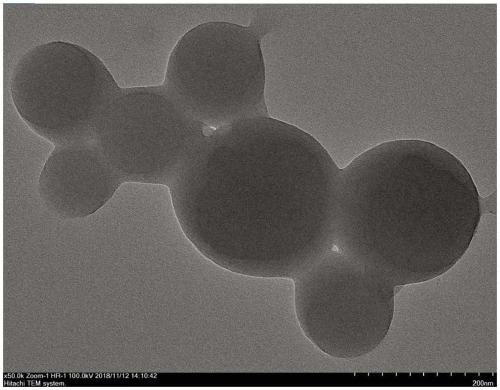

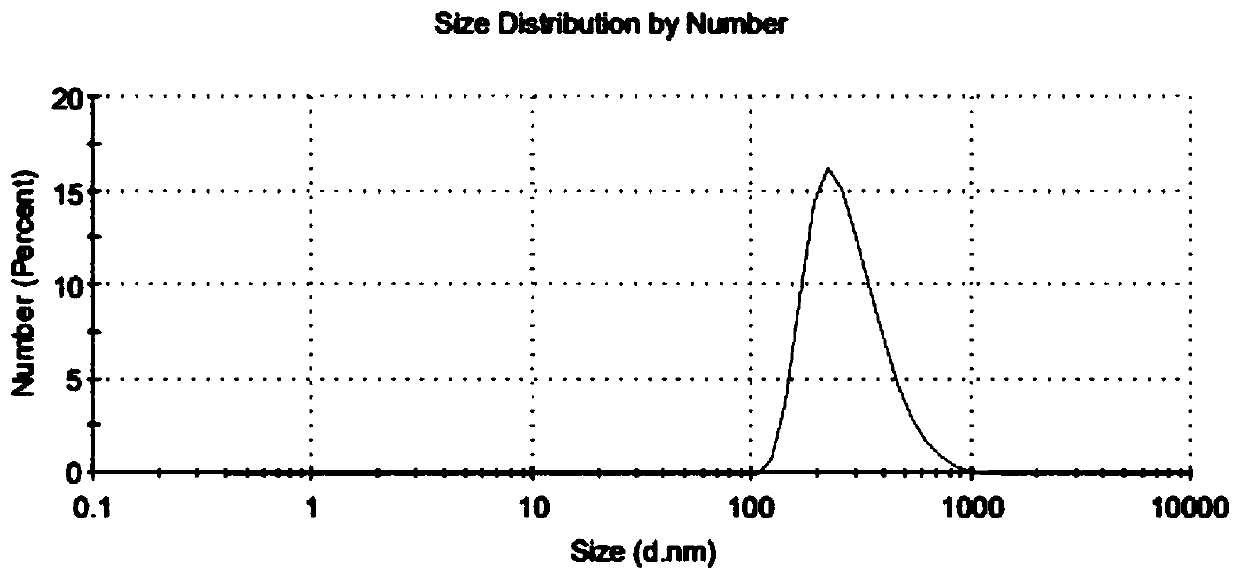

Image

Examples

preparation example Construction

[0062] 2. Preparation of modified micro-crosslinked urea-formaldehyde resin adhesive

[0063] (1) The raw material ratio of modified urea-formaldehyde resin adhesive

[0064] Wherein, the molar ratio of formaldehyde: urea: melamine: acrylamide: azobisisobutamidine hydrochloride to the total amount used is 2:1.4:0.4:0.2:0.002.

[0065] (2) The formula of modified urea-formaldehyde resin is shown in Table 2 below:

[0066] Table 2. Formula of modified urea-formaldehyde resin adhesive

[0067] raw material name Dosage (kg) formaldehyde171.5 Urea (1)67.2 Urea (2)16.8 Acrylamide14 Melamine50.4 Azodiisobutamidine hydrochloride0.45 20% sodium hydroxide Right amount 15% hydrogen chloride Right amount water Right amount

[0068] (3) Preparation process of modified urea-formaldehyde resin adhesive

[0069] Add the first batch of formaldehyde to the reactor and adjust its pH to 8.5-9, then add the first batch of urea to it, heat to 90°C and react for 30 minutes, then adjust its pH to 4...

Embodiment 1

[0071] A preparation method of urea-formaldehyde resin modified acrylate cationic emulsion and its interpenetrating network structure polymer includes the following steps (the following proportions are parts by weight, and the unit is kg):

[0072] 1) Preparation of cationic seed emulsion

[0073] The seed emulsion ratio is: cationic starch glue (25%) is 7.4, CTAB is 0.95, AIBA is 0.3, water is 160, St is 7.2, BA is 5.4, and HEA is 2.0.

[0074] Add the bottoming water to the reaction kettle, add dispersant (cationic starch dispersion with a mass concentration of 25%), emulsifier (cationic emulsifier or cationic reactive emulsifier), azobisisobutamidine hydrochloride during stirring After vacuum degassing, nitrogen is blown to drive oxygen and the temperature is raised. The primer monomer is added dropwise at 70°C. After dripping and keeping for 30 minutes, the primer seed emulsion is prepared.

[0075] 2) Preparation of pre-emulsion

[0076] The ratio of emulsification (water phase) o...

Embodiment 2

[0085] A preparation method of urea-formaldehyde resin modified acrylate cationic emulsion and its interpenetrating network structure polymer includes the following steps (the following proportions are parts by weight, and the unit is kg):

[0086] 1) Preparation of cationic seed emulsion

[0087] The seed emulsion ratio is: cationic starch glue (25%) is 7.4, CTAB is 0.95, AIBA is 0.3, water is 160, BA is 12.6, and HPA is 2.0.

[0088] Add the bottoming water to the reaction kettle, add dispersant (cationic starch dispersion with a mass concentration of 25%), emulsifier (cationic emulsifier or cationic reactive emulsifier), azobisisobutamidine hydrochloride during stirring After vacuum degassing, nitrogen is blown to drive oxygen and the temperature is raised. The primer monomer is added dropwise at 70°C. After dripping and keeping for 30 minutes, the primer seed emulsion is prepared.

[0089] 2) Preparation of pre-emulsion

[0090] The ratio of the emulsification (water phase) of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com