Method for conditioning and promoting excess sludge to produce methane through sodium ferrous chlorophyllin

A technology for excess sludge and chlorophyll, applied in biological sludge treatment, gas fuel, waste fuel, etc., can solve the problems of cumbersome operation, large amount of reagents, reagent residue, etc., and achieve simple operation, low dosage and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

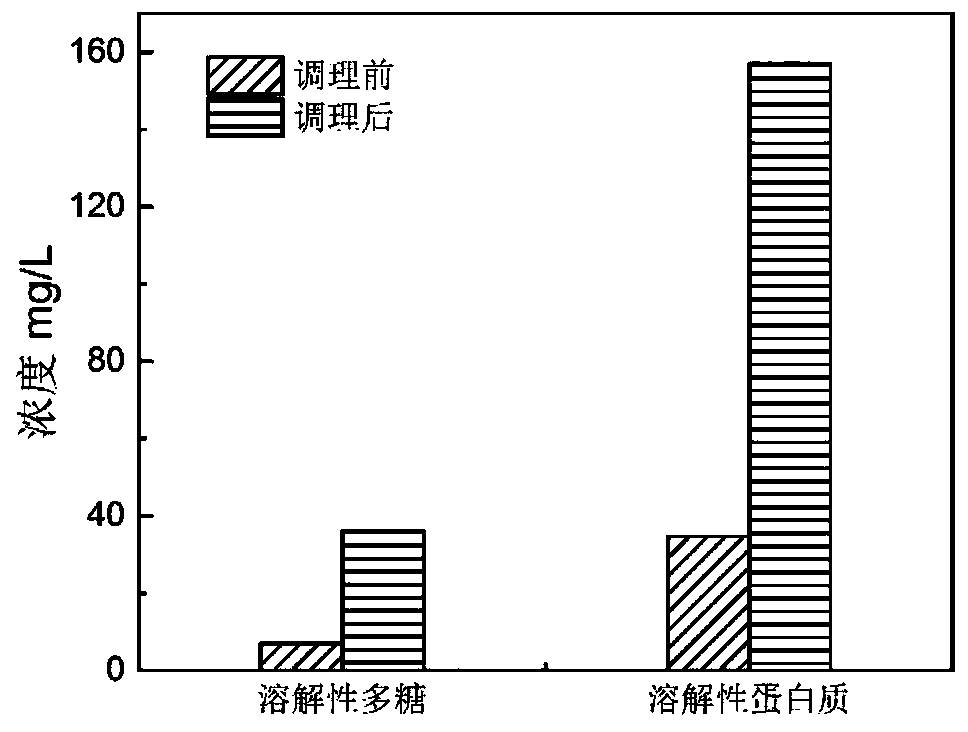

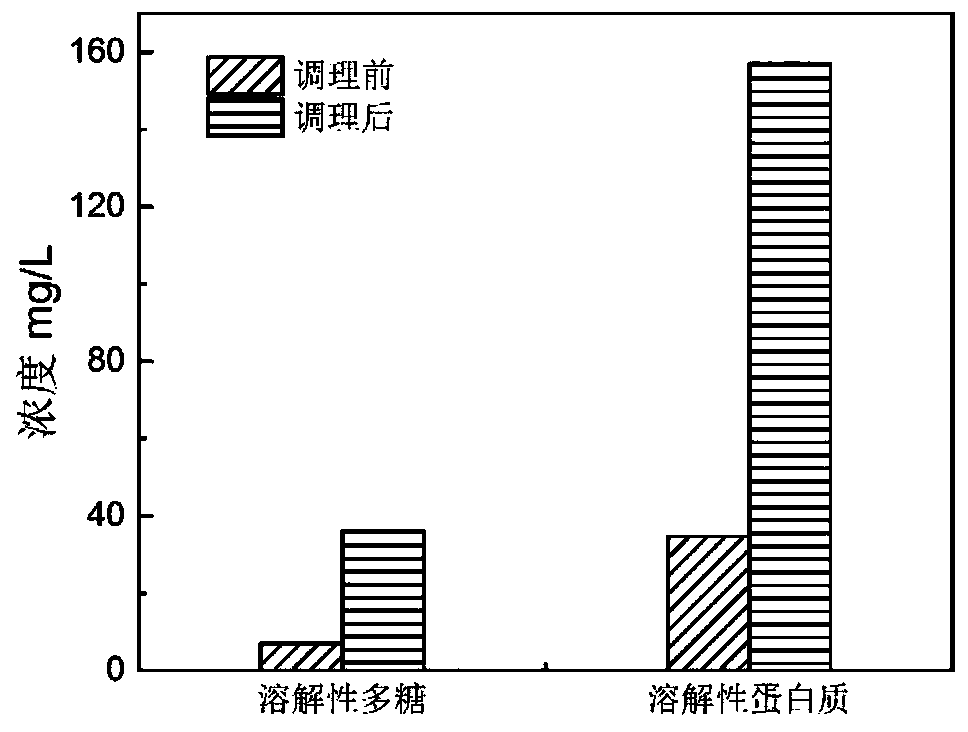

[0027] (I) Condition excess sludge with ferric chlorophyllin sodium salt: take 50mL residual sludge with a moisture content of 96.5% and place it in a beaker, place the beaker on a magnetic stirrer and stir at a speed of 500rpm, weigh 0.0071g of ferric chlorophyllin sodium salt into the beaker, and after stirring for 5 minutes, add 0.09 mL of 30% H 2 o 2 solution, stirred and conditioned for 100 min.

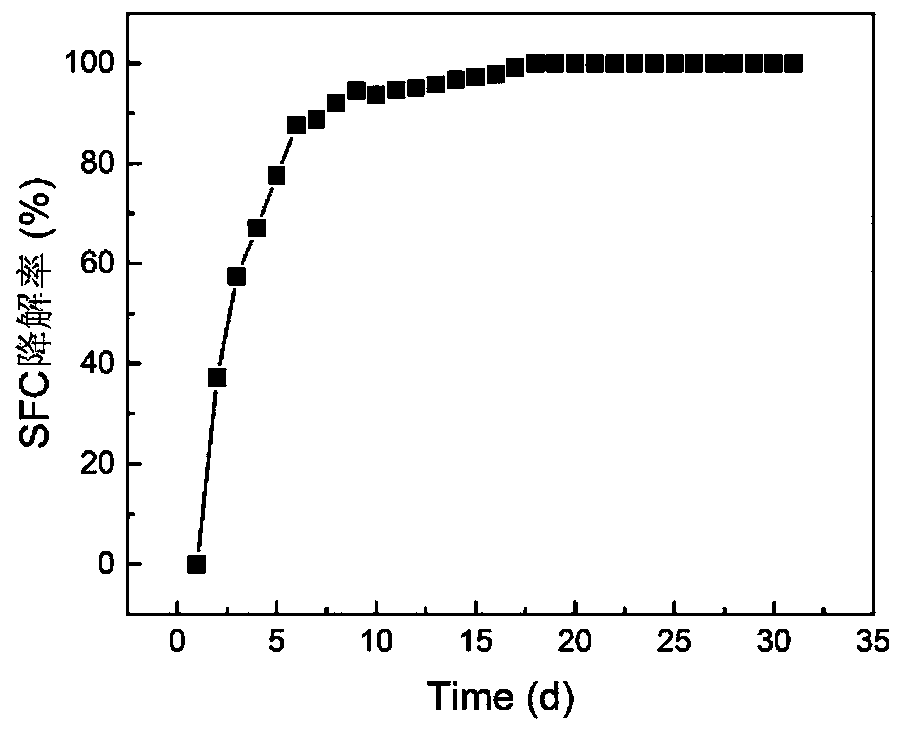

[0028] (II) Anaerobic digestion for methane production: mix the conditioned residual sludge with the mature anaerobic granular sludge in the brewery in step (I), and the inoculum amount of the anaerobic granular sludge is 10% of the total dry matter mass , the fermentation concentration is 5%, and the total volume of the anaerobic digestion reactor is 100mL. The reactor adopts a high boron glass container, and the opening is sealed with a silicone plug and silicone rubber. The anaerobic digestion reactor is placed in a constant temperature shaking incubator, and a water bath ...

Embodiment 2

[0030] (I) Condition excess sludge with ferric chlorophyllin sodium salt: take 100mL residual sludge with a moisture content of 99.5% and place it in a beaker, place the beaker on a magnetic stirrer and stir at a speed of 200rpm, weigh 0.013g of ferric chlorophyllin sodium salt into the beaker, and after stirring for 2 minutes, add 0.065mL of 30% H 2 o 2solution, stirring and conditioning for 140min. After conditioning, the capillary water absorption time of the sludge was 487.7s, compared with 184.4s of the original sludge, the sludge was fully degraded, and the floc cracking effect was good.

[0031] (II) Anaerobic digestion for methane production: mix the conditioned residual sludge with the mature anaerobic granular sludge in the brewery in step (I), and the inoculum amount of the anaerobic granular sludge is 10% of the total dry matter mass , the fermentation concentration is 5%, and the total volume of the anaerobic digestion reactor is 200mL. The reactor adopts a hig...

Embodiment 3

[0033] (I) Condition excess sludge with ferric chlorophyllin sodium salt: take 500mL residual sludge with a moisture content of 98.5% and place it in a beaker, place the beaker on a magnetic stirrer and stir at a speed of 400rpm, weigh 0.013g of ferric chlorophyllin sodium salt into the beaker, and after stirring for 4 minutes, add 0.16mL of 30% H 2 o 2 Solution, stirring and conditioning for 160min. After conditioning, the capillary water absorption time of the sludge was 447.6s, compared with 184.4s of the original sludge, the sludge was fully degraded, and the floc cracking effect was good.

[0034] (II) Anaerobic digestion for methane production: mix the conditioned residual sludge with the mature anaerobic granular sludge in the brewery in step (I), and the inoculation amount of the anaerobic granular sludge is 20% of the total dry matter mass , the fermentation concentration is 5%, and the total volume of the anaerobic digestion reactor is 550mL. The reactor adopts a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com