High-efficiency oxygen-enriched bubble machine

An oxygen and high-efficiency technology, applied in the field of high-efficiency oxygen-enriched bubble machines, can solve the problems of insufficient ground water, waste of oxygen, limited contact area, etc., and achieve the effects of improving service life, increasing oxygen concentration, and increasing dissolved oxygen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

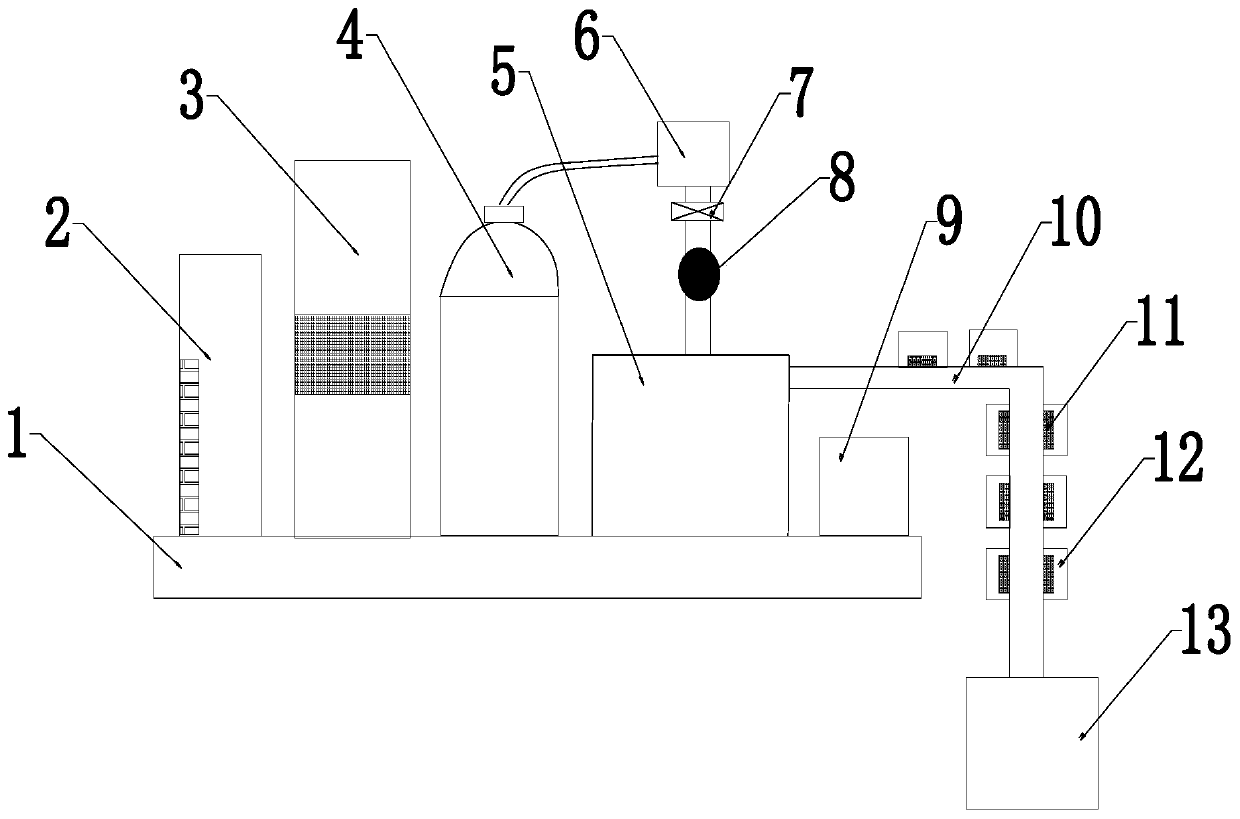

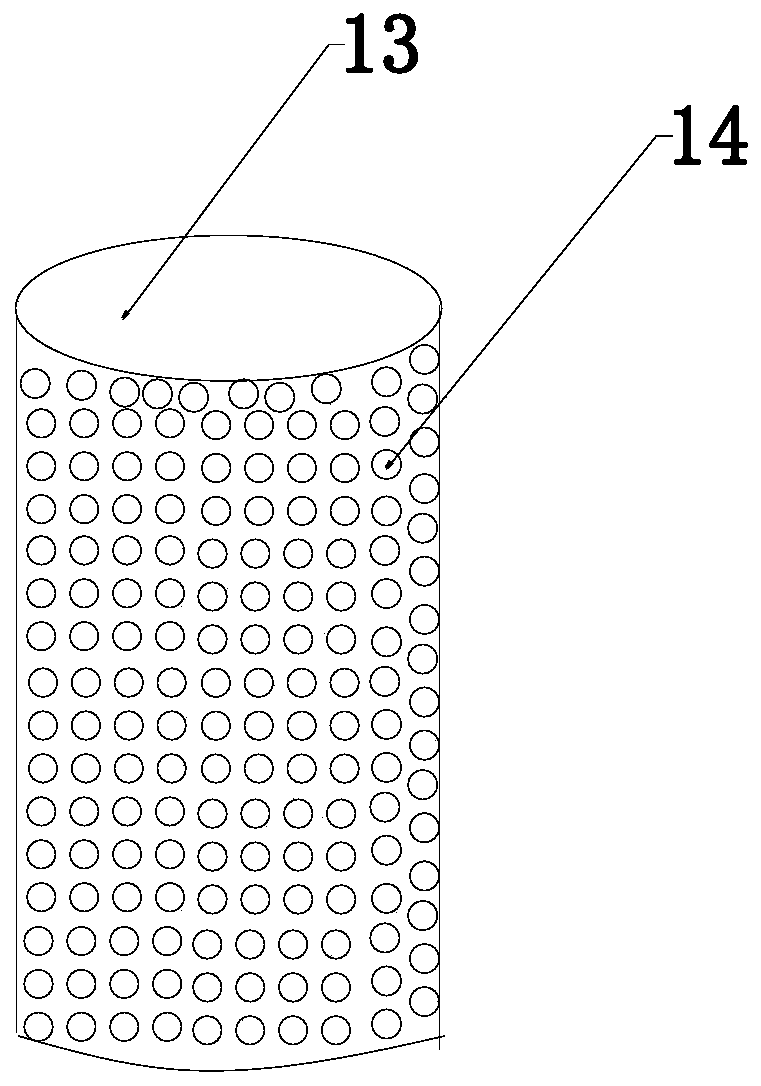

[0034] like figure 1 , figure 2 As shown, a high-efficiency oxygen-enriched bubble machine includes a bracket 1, a filter 2, a water pump 3, a mixer 5, an ultrasonic generator 9 and a dispersion chamber 13, and a filter 2, a water pump 3, and a mixer 5 are sequentially arranged on the bracket 1 And ultrasonic generator 9, ultrasonic generator 9 is located at the side close to dispersion chamber 13, and the output end pipeline of filter 2 is connected the input end of water pump 3, and the output end pipeline of water pump 3 is connected the input end of mixer 5, and mixer The output end of 5 is provided with ultrasonic pipeline 10, and at least one transducer 11 is arranged on the outer surface of ultrasonic pipeline 10, and the outlet end of ultrasonic pipeline 10 is connected with dispersion chamber 13, and the micropore 14 of matrix arrangement is established on the side wall of dispersion chamber 13, The upper end of the mixer 5 is connected to the oxygen storage tank 4 ...

Embodiment 2

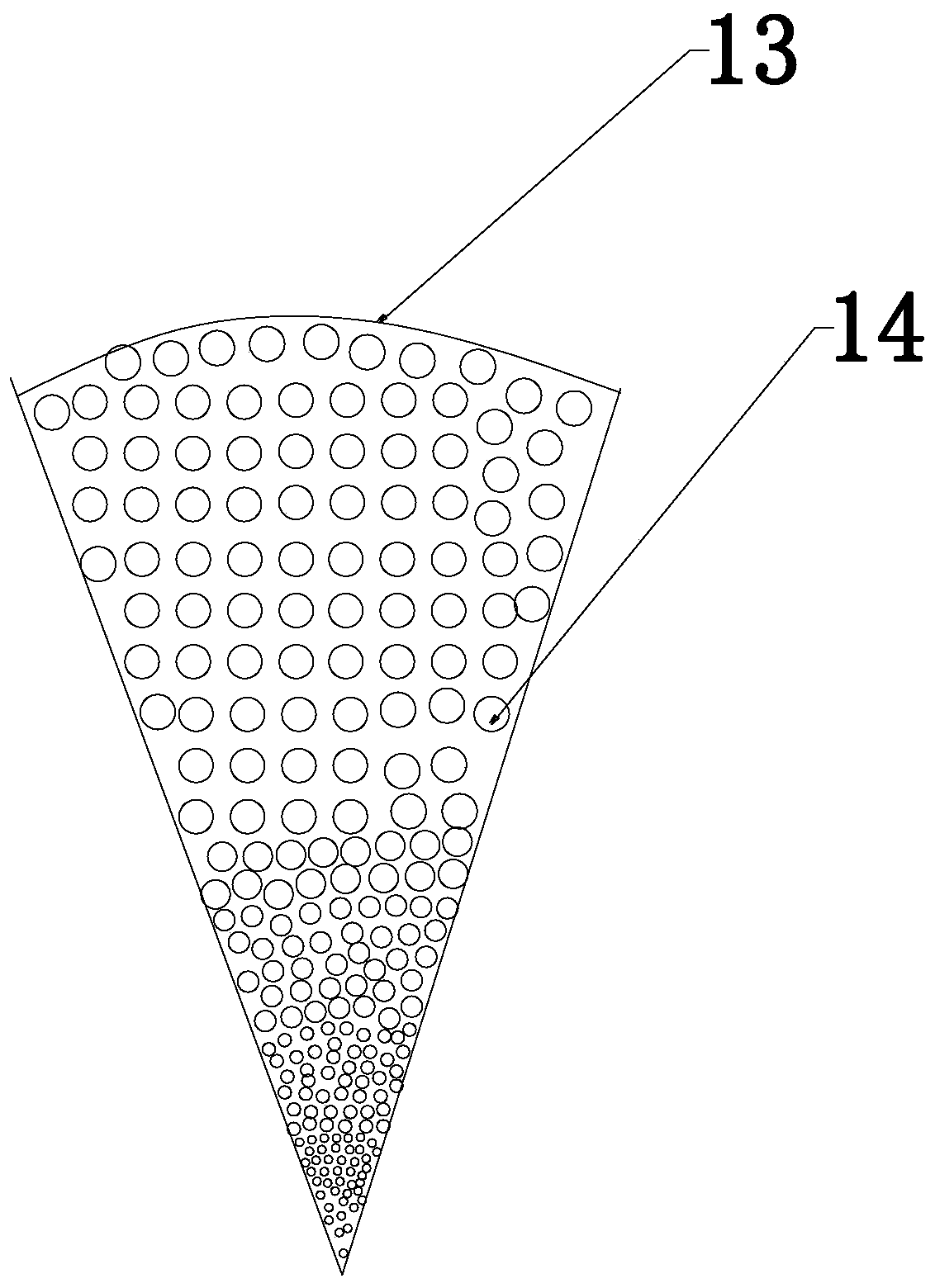

[0037] like figure 1 , image 3 As shown, a high-efficiency oxygen-enriched bubble machine includes a bracket 1, a filter 2, a water pump 3, a mixer 5, an ultrasonic generator 9 and a dispersion chamber 13, and a filter 2, a water pump 3, and a mixer 5 are sequentially arranged on the bracket 1 And ultrasonic generator 9, ultrasonic generator 9 is located at the side close to dispersion chamber 13, and the output end pipeline of filter 2 is connected the input end of water pump 3, and the output end pipeline of water pump 3 is connected the input end of mixer 5, and mixer The output end of 5 is provided with ultrasonic pipeline 10, and at least one transducer 11 is arranged on the outer surface of ultrasonic pipeline 10, and the outlet end of ultrasonic pipeline 10 is connected with dispersion chamber 13, and the micropore 14 of matrix arrangement is established on the side wall of dispersion chamber 13, The upper end of the mixer 5 is connected to the oxygen storage tank 4 t...

Embodiment 3

[0044] combine figure 1 , the gas and liquid are mixed in the Venturi mixer to form a gas-liquid mixed fluid, forming tiny bubbles. After the oscillation of the ultrasonic transducer on the ultrasonic pipeline, the tiny bubbles can be further decomposed into micro-nano bubbles by instantaneous stress. The ultrasonic transducer is used to convert electrical energy into mechanical energy, which becomes a mechanical oscillation of a certain frequency. The oscillation propagates in the gas-liquid mixed fluid, agitates the water body and gas, and greatly increases the dissolved oxygen in the water body. After ultrasonic oscillation The micro-nano bubbles generated in the end enter the dispersion chamber, and the micro-nano oxygen-enriched bubbles are branched into multiple channels through the micropores on the side wall of the dispersion chamber. Dissolved in the sewage to increase the oxygen concentration in the sewage, and finally achieve the purpose of purifying the sewage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com