Method of preparing nanomaterials in multiple structures from iron-rich low-grade clay minerals

A technology of clay minerals and nanomaterials, which is applied in the direction of nanotechnology, magnetic materials, and nanotechnology for materials and surface science, can solve the problems of waste of resources, deep color of clay minerals, and many associated minerals, and achieve stable quality. Efficient conversion and utilization, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

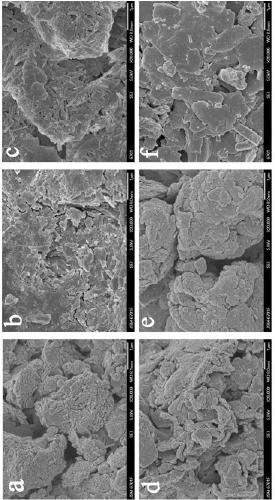

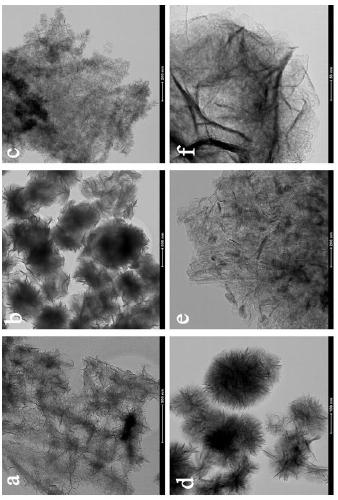

[0028] Red low-grade attapulgite clay mineral (SiO 2 Content 65%, Fe 2 o 3 Content 6%) crushed through a 200-mesh sieve. Take 1 kg and disperse it into 8 kg of 3.5 mol / L mixed acid (ascorbic acid: hydrochloric acid = 1:3 molar ratio) aqueous solution. After microwave hydrothermal treatment at 120 °C for 30 minutes, centrifuge and collect the supernatant to obtain solution B; the solid is dried , pulverized to obtain white powder A;

[0029] Weigh 200g of white powder A, disperse it into 3000g aqueous solution containing 90g of magnesium ions, add 40g of ammonium chloride, and then add ammonia water to adjust the pH value to 10, mix well, put it into a hydrothermal reaction kettle, seal it, and put it at a temperature of 160°C After reacting for 12 hours, cooling to room temperature, centrifuging, washing, and vacuum drying to obtain layered magnesium silicate nanomaterials;

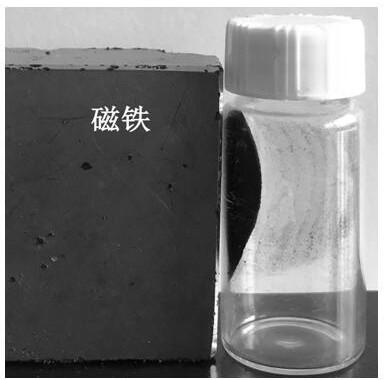

[0030] Add sodium hydroxide solution to solution B to adjust the pH value to 13, then reflux at 10...

Embodiment 2

[0032] Iron-rich low-grade bentonite (SiO 2 Content 50%, Fe 2 o 3Content 9.8%) crushed into powder and passed through 200 mesh sieve. Weigh 1 kg and disperse it into 8 kg of 3.5 mol / L mixed acid (ascorbic acid: hydrochloric acid = 1:3 molar ratio) aqueous solution. After microwave hydrothermal treatment at 120°C for 30 minutes, centrifuge and collect the centrifuged supernatant to obtain solution B. The solid was dried and pulverized to obtain white powder A;

[0033] Weigh 200g white powder A, disperse it into 3000g aqueous solution containing 240g zinc ions, add 200g ammonium sulfate, then add ammonia water to adjust the pH value to 12, mix well, put it into a hydrothermal reactor, seal it, and react at a temperature of 120°C 12h, after cooling to room temperature, centrifuge, wash, and vacuum-dry to obtain zinc silicate nanomaterials with nanoflower-like morphology;

[0034] Add sodium hydroxide solution to solution B, adjust the pH value of the solution to 10, then rea...

Embodiment 3

[0036] Iron-rich sepiolite (SiO 2 Content 56%, Fe 2 o 3 Content 7.8%) crushed into powder and passed through 200 mesh sieve. Weigh 1 kg, disperse it into 8 kg of 3.5 mol / L mixed acid (ascorbic acid: hydrochloric acid = 1:3 molar ratio) aqueous solution, and after microwave hydrothermal treatment at 120°C for 30 minutes, centrifuge and collect the centrifuged supernatant to obtain a solution B; The solid is dried and pulverized to obtain a white powder A;

[0037] Weigh 200g of white powder A, disperse it into 3000g of aqueous solution containing 200g of nickel ions, add 100g of ammonium nitrate, then add ammonia water to adjust the pH value to 11, mix well and put it into a microwave hydrothermal reaction kettle, seal it, and store it at a temperature of 140°C After reacting for 12 hours, cooling to room temperature, performing centrifugation, washing, and vacuum drying to obtain nanomaterials with nano-cluster morphology;

[0038] Add sodium hydroxide solution to solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com