Device for testing shape memory performance of thermal response material based on bending deformation method

A technology of bending deformation and thermal response, applied in the direction of applying stable bending force to test the strength of materials, measuring devices, and analyzing materials. Image post-processing program, convenient for large-scale application, and the effect of improving the efficiency of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

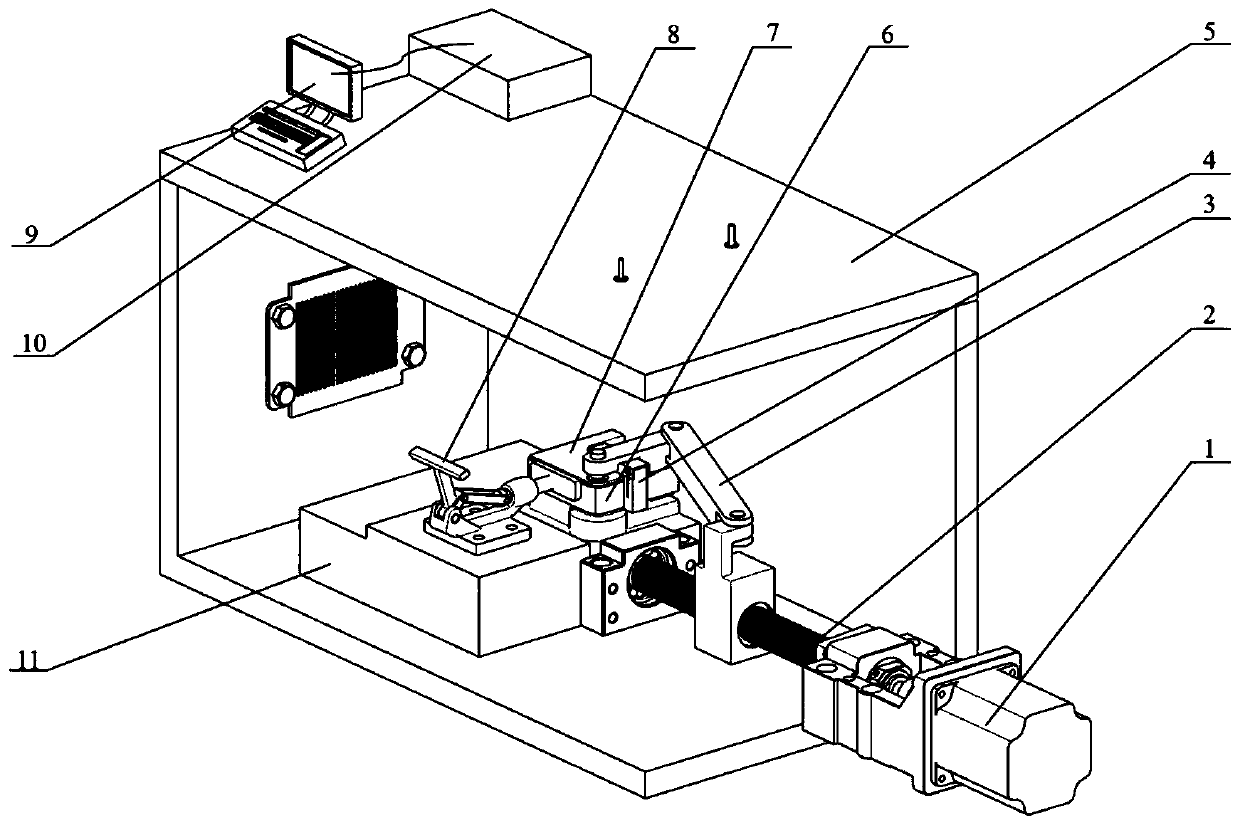

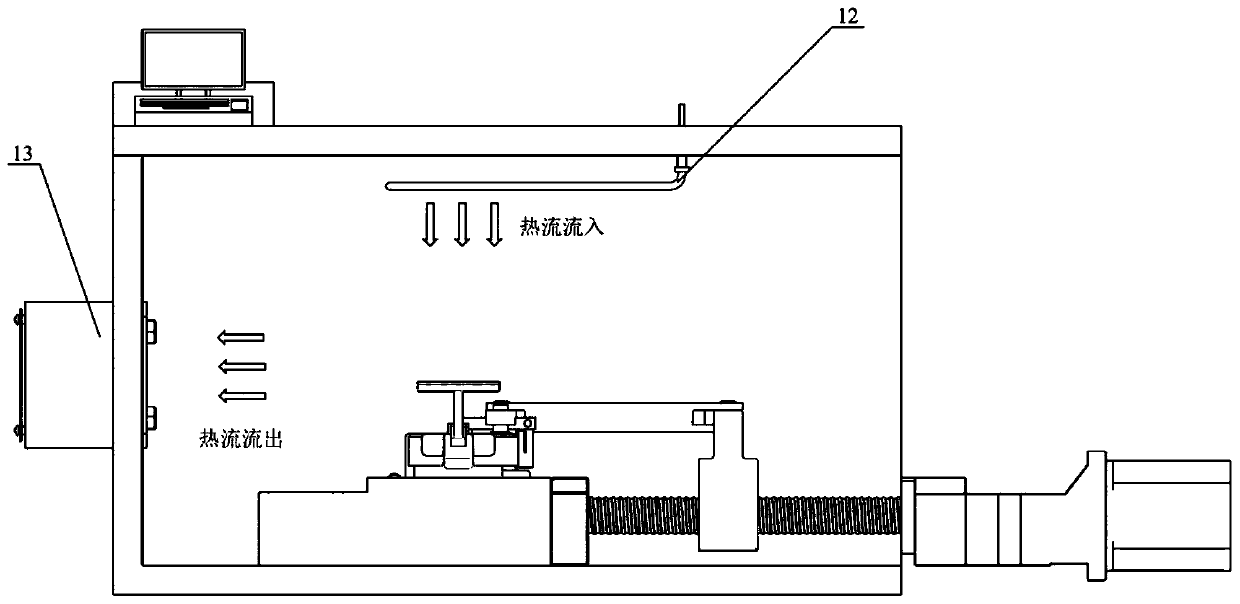

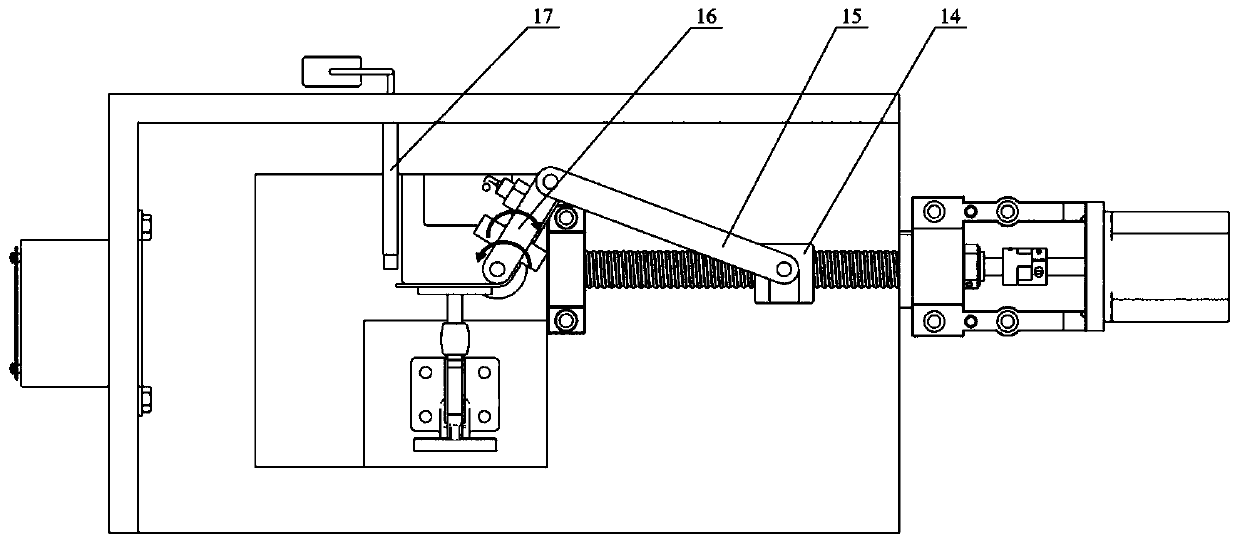

[0029] Such as figure 1 As shown, the device for testing the shape memory performance of thermally responsive materials based on the bending deformation method of the present invention includes an experiment box 5, a temperature control module, a bending deformation module, a measurement module, and a control and display module.

[0030] There is a test bench 11 in the test box 5, and a push-pull quick clamp 8 and a square block 7 are installed on the test bench 11 as a clamping device for fixing the sample 6. One end is fixedly clamped on the side of square block 7. During the test, the sample 6 was bent into an "L" shape and adhered to the two sides of the square block 7, and the characteristic values of the shape memory effect - shape fixation rate and shape recover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com