Catalyst for preparing biological aircraft fuel component from barbados nut oil and preparation method of biological aircraft fuel component

A technology of aviation fuel and catalyst, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of reducing the calorific value and chemical stability of fuel oil, achieve good industrial application prospects, simple preparation process, The effect of high fuel yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

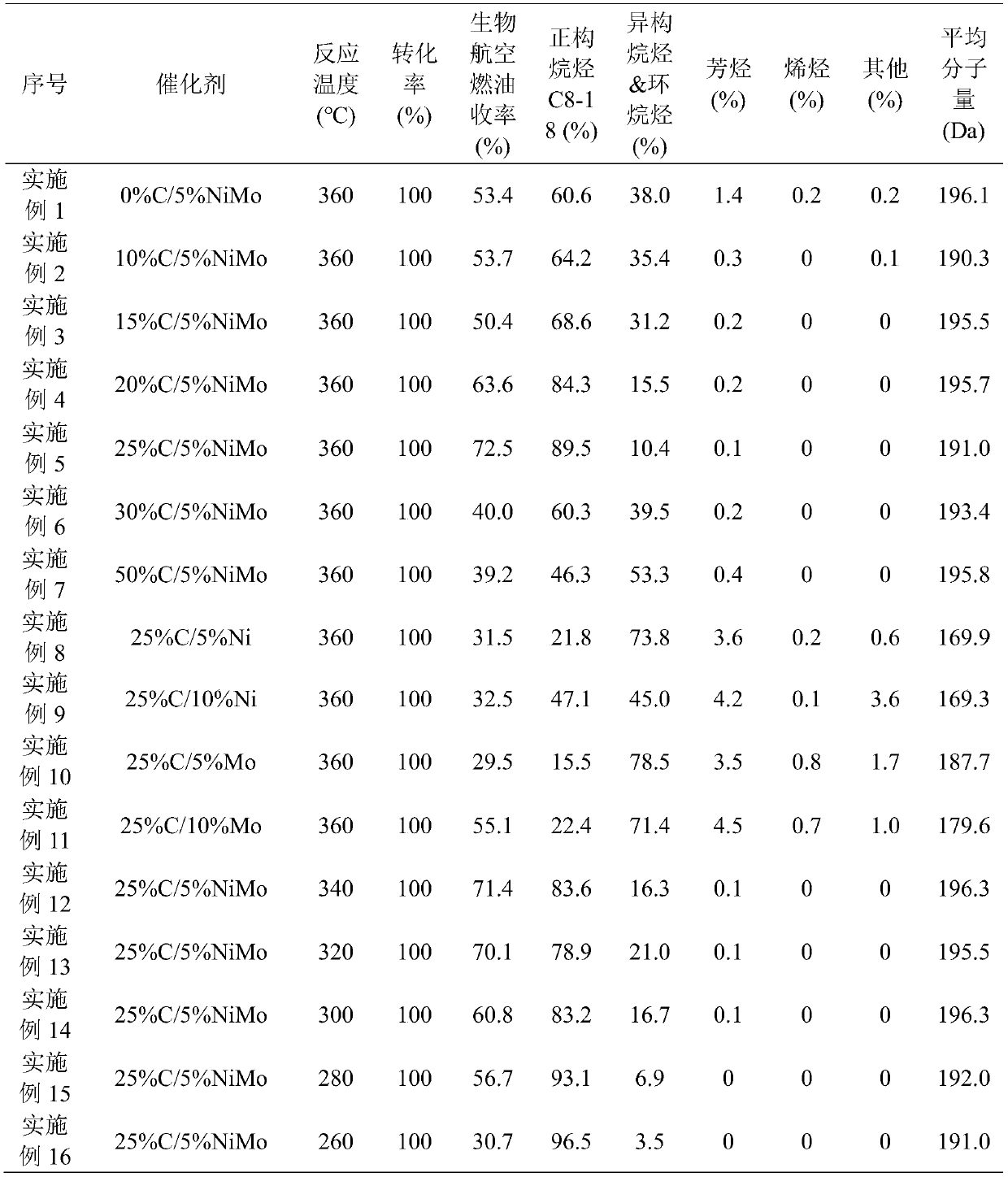

Examples

Embodiment 1

[0021] The preparation of embodiment 1.0%C / 5%NiMo catalyst

[0022] (1) Take the calculated amount of nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 2 o 24 4H 2 O) Aqueous solution (the mass fractions of Ni and Mo are respectively 5% of the mass fraction of the MCM-41 carrier) is added to the carrier MCM-41, and the conventional impregnation method is used to ultrasonicate for 30 minutes in a KQ-300E ultrasonic cleaner, and the Stir with a magnetic stirrer for 4 hours, soak overnight, evaporate to dryness in an oil bath at 80°C, place in an oven at 100-110°C for 3 hours, heat up to 600°C at 2°C / min, and roast for 4 hours to obtain a Ni / Mo / MCM-41 precursor .

[0023] (2) Take a certain amount of Ni / Mo / MCM-41 precursor prepared in (1) and put it in the fixed bed reduction tube, N 2After purging the air path, under the hydrogen atmosphere (40mL / min), the temperature was raised to 350°C at room temperature at 5°C / min, an...

Embodiment 210

[0025] The preparation of embodiment 2.10%C / 5%NiMo catalyst

[0026] (1) Take the calculated amount of nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 2 o 24 4H 2 O) Aqueous solution (the mass fractions of Ni and Mo are respectively 5% of the mass fraction of the MCM-41 carrier) is added to the carrier MCM-41, and the conventional impregnation method is used to ultrasonicate for 30 minutes in a KQ-300E ultrasonic cleaner, and the Stir with a magnetic stirrer for 4 hours, soak overnight, evaporate to dryness in an oil bath at 80°C, place in an oven at 100-110°C for 3 hours, heat up to 600°C at 2°C / min, and roast for 4 hours to obtain a Ni / Mo / MCM-41 precursor .

[0027] (2) Take a certain amount of Ni / Mo / MCM-41 precursor prepared in (1) and put it in the fixed bed reduction tube, N 2 After purging the air path, under the hydrogen atmosphere (40mL / min), the temperature was raised to 350°C at room temperature at 5°C / min, ...

Embodiment 315

[0029] The preparation of embodiment 3.15%C / 5%NiMo catalyst

[0030] (1) Take the calculated amount of nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 2 o 24 4H 2 O) Aqueous solution (the mass fractions of Ni and Mo are respectively 5% of the mass fraction of the MCM-41 carrier) is added to the carrier MCM-41, and the conventional impregnation method is used to ultrasonicate for 30 minutes in a KQ-300E ultrasonic cleaner, and the Stir with a magnetic stirrer for 4 hours, soak overnight, evaporate to dryness in an oil bath at 80°C, place in an oven at 100-110°C for 3 hours, heat up to 600°C at 2°C / min, and roast for 4 hours to obtain a Ni / Mo / MCM-41 precursor .

[0031] (2) Take a certain amount of Ni / Mo / MCM-41 precursor prepared in (1) and put it in the fixed bed reduction tube, N 2 After purging the air path, under the hydrogen atmosphere (40mL / min), the temperature was raised to 350°C at room temperature at 5°C / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com