Remote monitoring system for engineering machinery equipment data

A remote monitoring system and equipment data technology, applied in the transmission system, force/torque/power measuring instrument, measuring device, etc., can solve the problems of high misoperation rate, slow measurement process, large reading error, etc., and achieve a breakthrough in geographical restrictions , facilitate quality management, and improve execution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

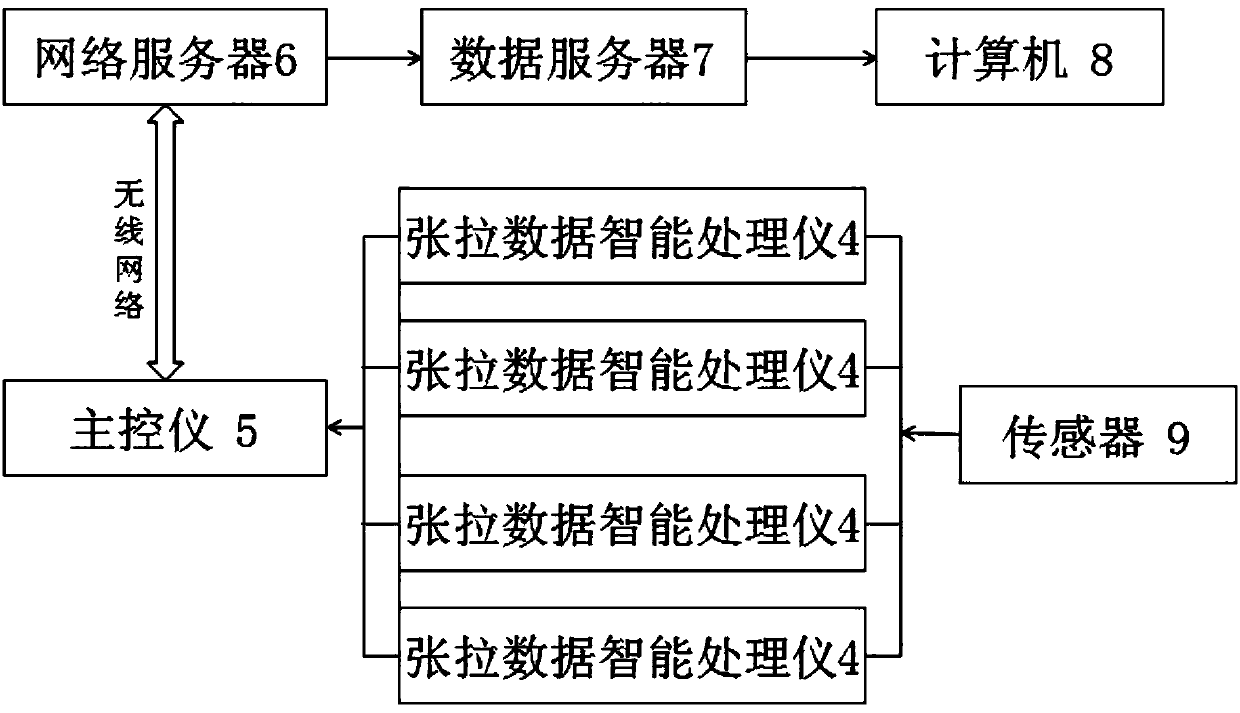

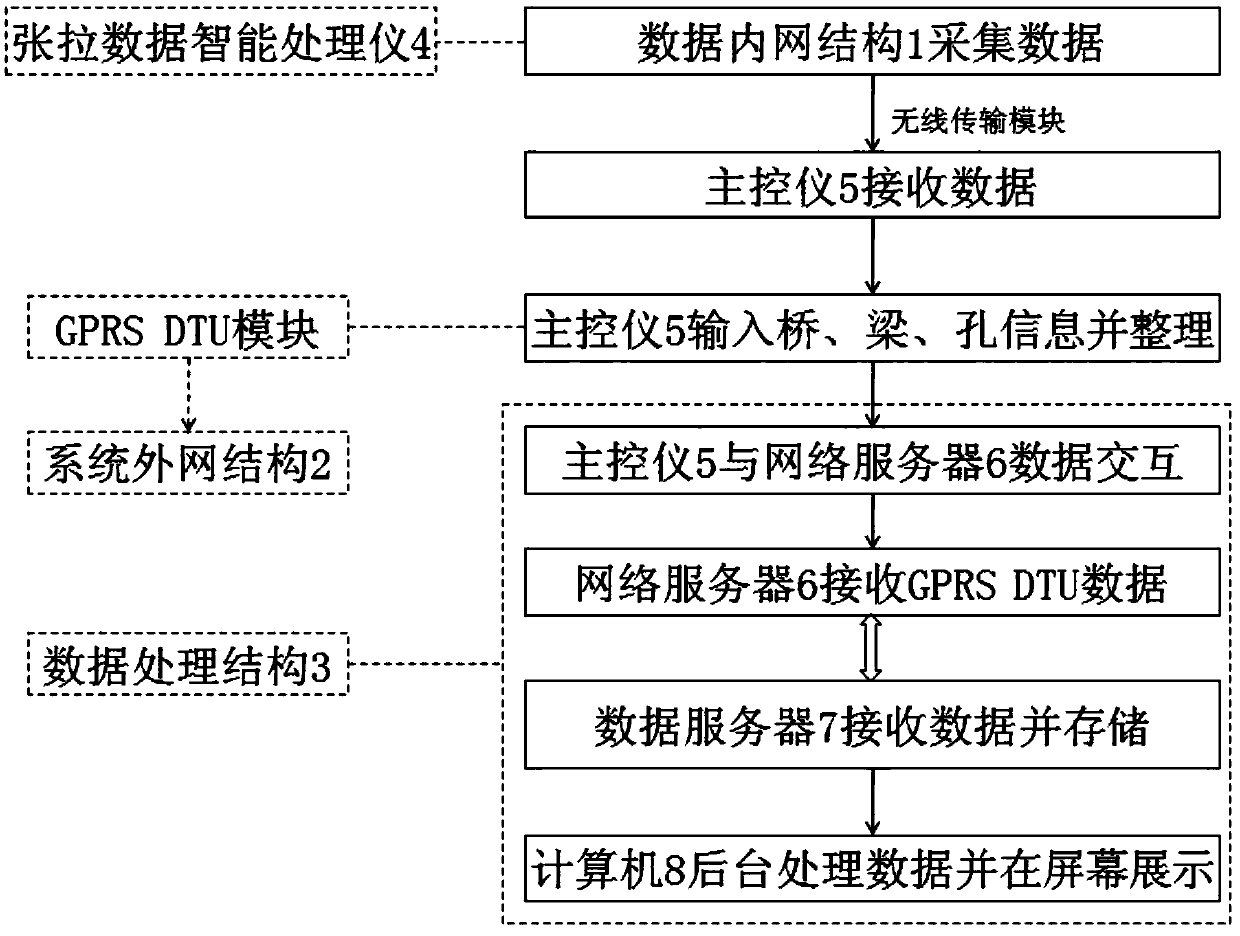

[0032] like Figure 1-2 The shown remote monitoring system for construction machinery equipment data includes a data intranet structure 1, which is used for data collection in the working process of the entire system;

[0033] The system external network structure 2 is used to transmit the data collected by the data internal network structure 1;

[0034] Data processing structure 3, used for data processing and display;

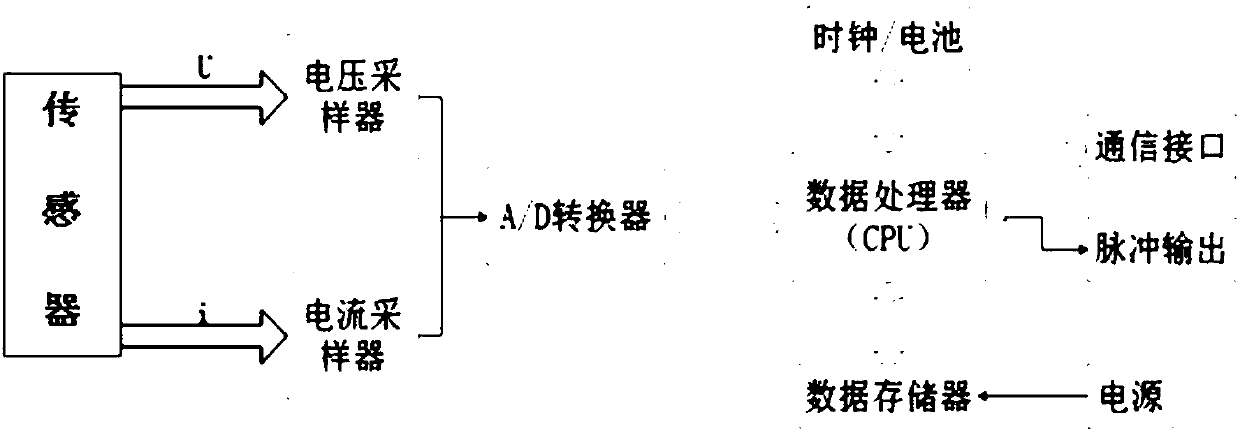

[0035] The data intranet structure 1 includes several tension data intelligent processing instruments 4;

[0036] Further, the system external network structure 2 includes the GPRSDTU module embedded in the main controller 5; the main controller 5 adopts a 7-inch large screen for data input according to the on-site environment and operation requirements, which greatly improves the input of bridge basic information. Efficiency, also adopts aluminum alloy material withholding structure.

[0037] Further, the data processing structure 3 includes a network ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com