Composition, preparation method and application of composition to ion battery positive electrode material

A composition and raw material technology, applied in the field of lithium-ion batteries, can solve problems such as complex process and high cost, and achieve the effects of simple and reliable process, improved processing performance, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

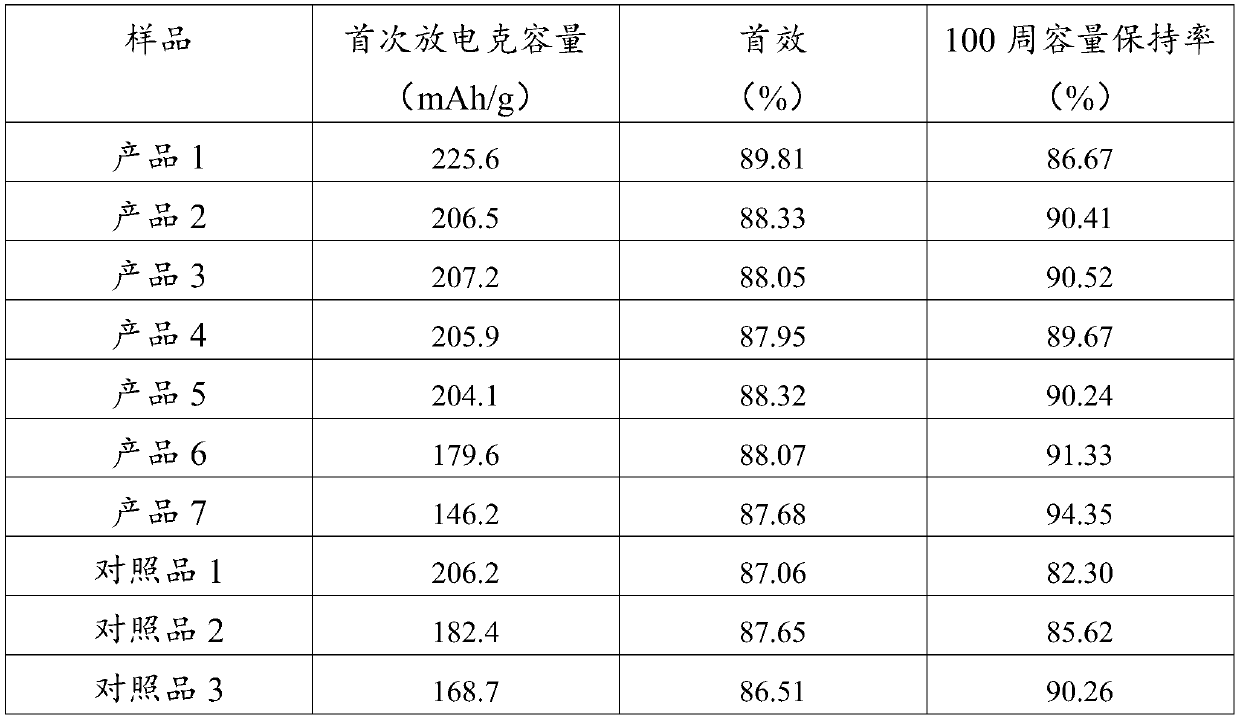

Embodiment 1

[0027] After 100g lithium nickel cobalt manganese oxide 1 is mixed with 100g liquid phase solvent 1, stir 30min with the rotating speed of 1500r / min, add 10g nano zirconium sol (solid content 20%, pH is less than 7) and stir 40min with the rotating speed of 1000r / min, Obtain slurry 1. In this embodiment, the molar ratio of nickel, cobalt, and manganese in nickel-cobalt lithium manganese oxide 1 is 90:5:5, and the liquid phase solvent 1 is deionized water.

[0028] Slurry 1 was filtered, dried and heat-treated in sequence to obtain Product 1. In this embodiment, the heat treatment method is as follows: in an oxygen atmosphere, treat at 900° C. for 8 hours and then cool to room temperature.

Embodiment 2

[0030] After 90g lithium nickel cobalt manganese oxide 2 is mixed with 80g liquid phase solvent 2, stir 10min with the rotating speed of 1000r / min, add 5g nano aluminum sol (solid content 20%, pH is less than 7) and stir 30min with the rotating speed of 1000r / min, Obtain slurry 2. In this embodiment, the molar ratio of nickel, cobalt, and manganese in nickel-cobalt lithium manganate 2 is 80:10:10, and the liquid phase solvent 2 is ethanol.

[0031] Slurry 2 is filtered, dried and heat-treated in sequence to obtain product 2. In this embodiment, the heat treatment method is as follows: in an oxygen atmosphere, treat at 300° C. for 12 hours and then cool to room temperature.

Embodiment 3

[0033] After 100g lithium nickel cobalt manganese oxide 3 is mixed with 150g liquid phase solvent 3, stir 5min with the rotating speed of 800r / min, add 15g nano-titanium sol (solid content 20%, pH is less than 7) after stirring 20min with the rotating speed of 1500r / min, Obtain slurry 3. In this embodiment, the molar ratio of nickel, cobalt, and manganese in nickel-cobalt lithium manganate 3 is 80:10:10, and the liquid phase solvent 3 is propanol.

[0034] Slurry 3 was filtered, dried and heat-treated in sequence to obtain product 3. In this embodiment, the heat treatment method is as follows: in an oxygen atmosphere, treat at 300° C. for 6 hours and then cool to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com