Vehicle lamp light source device and vehicle lamp module

A light source and vehicle lamp technology, which is applied in the automotive field, can solve the problems of reducing the visible distance of road signs, weakening, and reducing driving safety, etc., and achieves the effects of improving the visible distance, high safety factor, and reducing heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

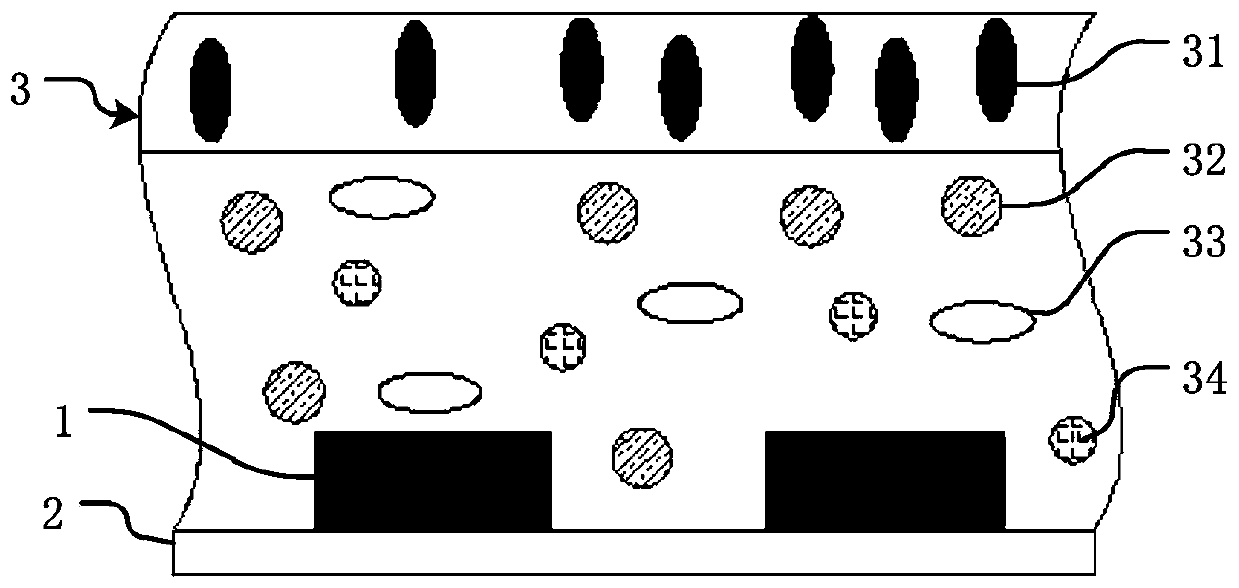

[0082] The light source adopts a formally installed NUV crystal element 1 and is placed in the PLCC / ceramic multi-bowl holder 2. The NUV crystal element 1 is fixed on the positive and negative electrodes at the bottom of the PLCC / ceramic multi-bowl holder 2 through crystal bonding glue, and is respectively connected by metal wires 11. Connect the positive and negative terminals 21 of the NUV crystal unit 1 and the internal electrode of the PLCC / ceramic multi-bowl cup holder 2, the phosphor silica gel layer 3 is filled with the PLCC / ceramic multi-bowl cup holder 2, and the layering methods of phosphors of different colors are set as described above . Its installation structure is as Figure 8 , Figure 11 shown.

Embodiment 2

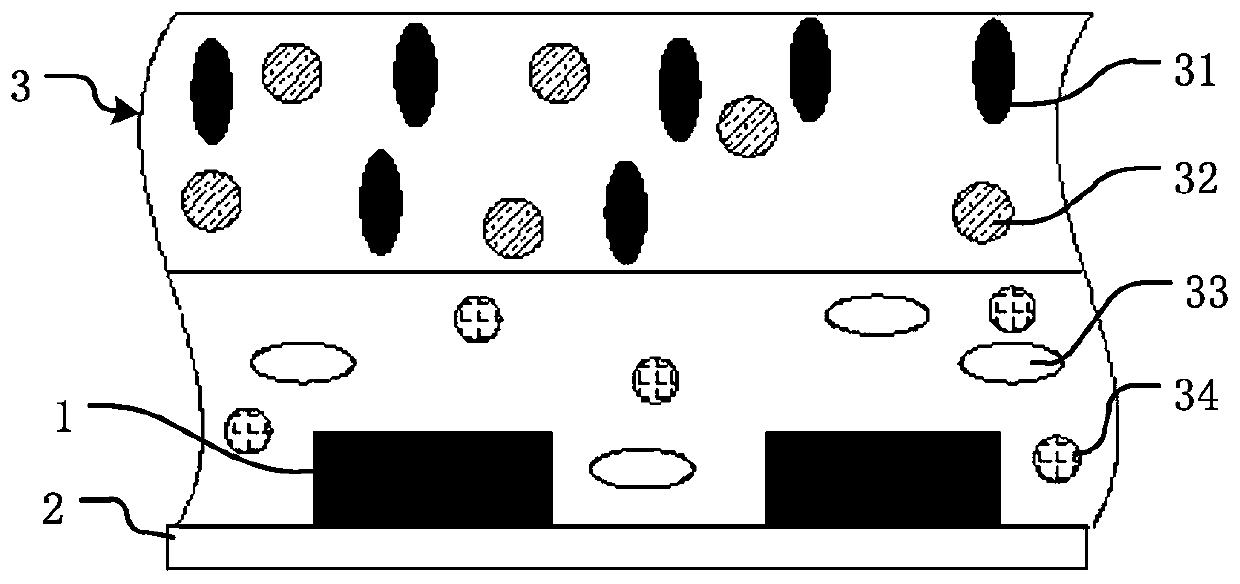

[0084] The light source is placed in the PLCC / ceramic multi-bowl cup holder 2 by flip-chip NUV crystal unit 1, and the NUV crystal unit 1 is connected to the internal positive and negative electrodes 21 of the electrodes of the PLCC / ceramic multi-bowl cup holder 2 through soldering tin, and the phosphor powder silica gel layer 3 is filled The PLCC / ceramic multi-bowl support 2 is filled, and a white glue reflective layer (optional) 8 is coated between the fluorescent powder silica gel layer 3 and the bottom of the PLCC / ceramic multi-bowl support 2 . Its installation structure is as Figure 9 , Figure 12 shown.

Embodiment 3

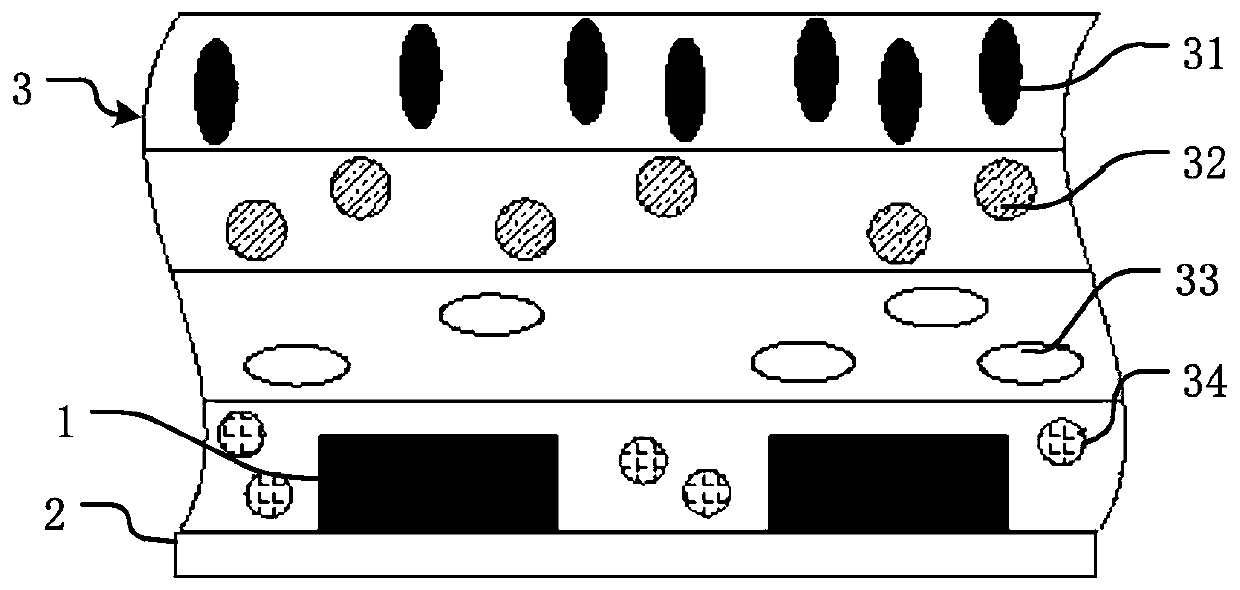

[0086] The light source is placed in the PLCC / ceramic multi-bowl holder 2 by flip-chip NUV crystal unit 1, and the NUV wafer 1 is respectively connected to the internal positive and negative electrodes 21 of the electrodes of the PLCC / ceramic multi-bowl holder 2 through the solder cap 121 of the copper pillar 12, Phosphor powder silica gel layer 3 is filled with PLCC / ceramic multi-bowl cup support 2, and the metal surface at the bottom of PLCC / ceramic multi-bowl cup support 2 is plated with a highly reflective metal coating, such as a silver layer, or in phosphor silica gel layer 3 and PLCC / A white glue reflective layer is coated between the bottoms of the multi-bowl support 2 of the ceramics. Its installation structure is as Figure 10 , Figure 13 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com