Louver leaf coating and preparation method thereof

A technology for blinds and blades, which is applied to coatings, devices for coating liquid on surfaces, and pre-treated surfaces, etc. It can solve the problems of poor bending resistance and single function of the coating of shutter blades, and achieve improved waterproof performance and decomposition The best effect, the effect of improving the bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A louver blade coating provided by the invention includes: coating on the woven fabric blade, including an inner coating film and an outer coating film; the formula of the inner coating film contains modified polyvinyl acetate polymer Stiffening agent and water of polymer, wherein the percentage by weight of stiffening agent is 20%; In the prescription of described outer coating film, comprise waterproofing agent, nanometer titanium dioxide and water, wherein the weight percent of organic fluororesin C6 waterproofing agent, nanometer titanium dioxide are respectively 3% and 0.3%.

Embodiment 2

[0030] A louver blade coating provided by the invention includes: coating on the woven fabric blade, including an inner coating film and an outer coating film; the formula of the inner coating film contains modified polyvinyl acetate polymer Stiffening agent and water of polymer, wherein the percentage by weight of stiffening agent is 30%; In the formula of described outer coating film, comprise waterproofing agent, nanometer titanium dioxide and water, wherein the weight percent of organic fluororesin C6 waterproofing agent, nanometer titanium dioxide are respectively 8% and 0.8%.

Embodiment 3

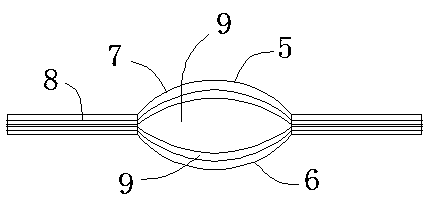

[0032] like figure 1 , figure 2 Shown; The present invention also provides a kind of preparation method of louver blade coating, comprises the following steps:

[0033] 1) Mix the stiffening agent and water according to the ratio to form the inner coating film mixture;

[0034] 2) The louver blades are dipped, and the inner coating film mixture is evenly coated on the surface of the blades and the inside of the weaving gap; then baked at 60-℃ for 3 minutes to form a hardened inner coating film;

[0035] 3) Mix waterproofing agent, nano-titanium dioxide and water in proportion to form an outer coating film mixture;

[0036] 4) Dip the louver blades with the hardened inner coating film to evenly coat the coating on the surface of the protective film; then bake at 60°C for 3 minutes to form a hardened outer coating film.

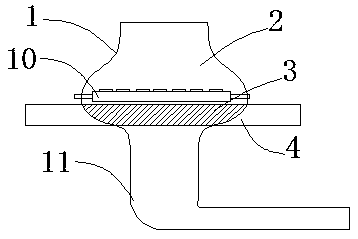

[0037] The baking in step 2) and step 4) is carried out in a baking device. The baking device includes a long box 1, and the box includes an inverted bucket-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com