Drilling fluid bridging particle, preparation method thereof, and drilling fluid plugging agent

A technology of drilling fluid and lost circulation agent, which is applied in the fields of plugging agent for drilling fluid and bridging lost circulation agent for drilling fluid. The effect of reducing the leakage amount and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

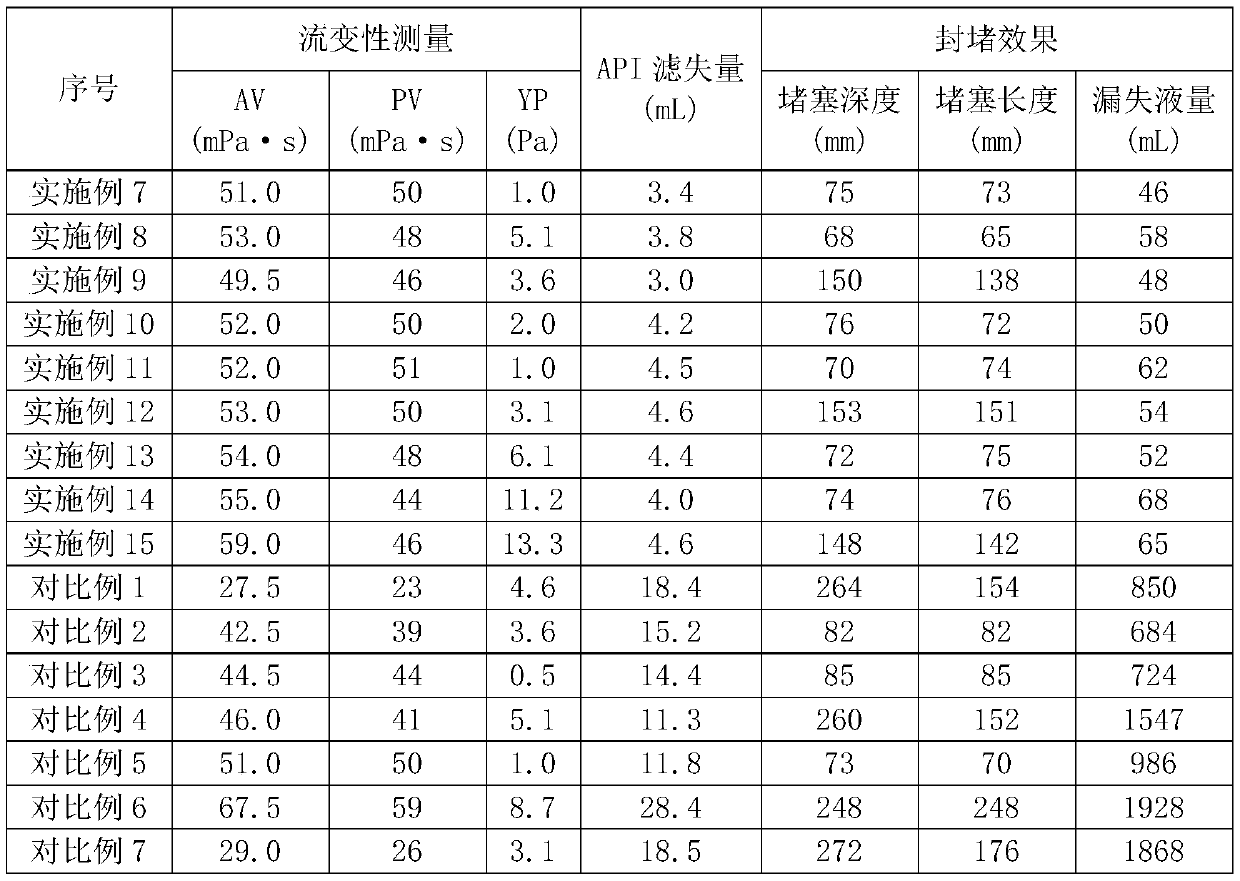

Examples

Embodiment 1

[0033] The bridging and plugging agent for drilling fluid in this embodiment comprises: by weight percentage, 40% of sand and 60% of filling material; wherein, the sand includes primary sand with a particle diameter of 0.2mm, and the particle diameter is 0.1mm The mass ratio of the primary sand to the secondary sand is 1:0.8, and the filling material includes a rigid material and a variable material with a mass ratio of 1:0.8, and the rigid material has a particle size of 0.02mm ultrafine calcium carbonate powder, and the variable material is graphite powder with a particle diameter of 0.01mm.

Embodiment 2

[0035] The bridging and plugging agent for drilling fluid of the present embodiment includes: by weight percentage, 60% of sand and 40% of filling material; wherein, the sand includes primary sand with a particle diameter of 0.25mm, and the particle diameter is 0.2mm The mass ratio of the primary sand grains to the secondary sand grains is 1:1, and the filling material includes a rigid material and a variable material with a mass ratio of 1:1.2, and the rigid material has a particle size of 0.08mm silica powder, the variable material is asphalt powder with a particle size of 0.06mm.

Embodiment 3

[0037] The bridging and plugging agent for drilling fluid of the present embodiment comprises: by weight percentage, 55% of sand grains and 45% of filling materials; wherein, the sand grains include primary sand grains with a grain diameter of 0.24mm, and the grain diameter is 0.12mm The mass ratio of primary sand to secondary sand is 1:1.2. The filling material includes rigid material and variable material with a mass ratio of 1:1. The rigid material has a particle size of 0.06mm ultrafine calcium carbonate powder, the variable material is elastic graphite powder with a particle diameter of 0.03mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com