Modified polyurethane foam and preparation method and applications thereof

A polyurethane and foam technology is applied in the field of resource utilization of foam materials to achieve the effects of improved mechanical properties and mechanical properties, low experimental consumables, and high resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Preparation of polyurethane foam

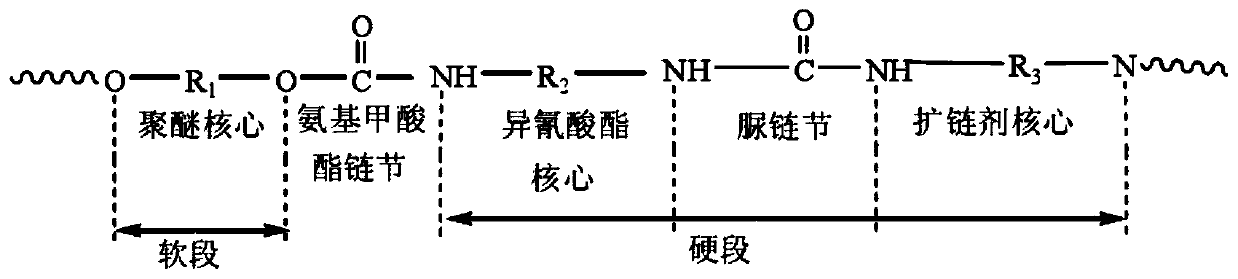

[0059] According to the ratio, polyurethane black material (forming the hard segment of polyurethane foam) and polyurethane white material (forming the soft segment of polyurethane foam) are mixed under stirring at 250 rpm to obtain a polyurethane foam prepolymer, and then the polyurethane Foaming prepolymer The polyurethane foaming prepolymer is poured into a mold, and left to stand at room temperature for 10 minutes, demolded to obtain a sample, and the sample is aged at room temperature for 24 hours to obtain a polyurethane foam.

[0060] In this comparative example, adding polyurethane black material, polyurethane white material mass ratio is 2:8, 5:5, 6:4, 7:3, 8:2 respectively, finally obtains 5 groups of polyurethane foams, the obtained polyurethane foam The mass ratio of the hard and soft segments in the foam is 2:8, 5:5, 6:4, 7:3, and 8:2 respectively. Observe whether the shape of the polyurethane foam with the above ratio of ...

Embodiment 2

[0062] Preparation of Modified Polyurethane Foam

[0063] Mix polyurethane black material, polyurethane white material, expanded perlite, and rice husk ash according to the ratio under stirring at 250 rpm to obtain a polyurethane foam prepolymer, and then make the polyurethane foam prepolymer polyurethane foam prepolymer Pour the body into the mold, let it stand at room temperature for 10 minutes, then add the hydroxyl-terminated polyepichlorohydrin solution, then place it in an oven at 110°C for 24 hours, demould to obtain a sample, and mature the sample for 24 hours at room temperature to obtain the modified polyurethane foam. bubble body.

[0064] The mass ratio of the polyurethane black material and the polyurethane white material is 5:5.

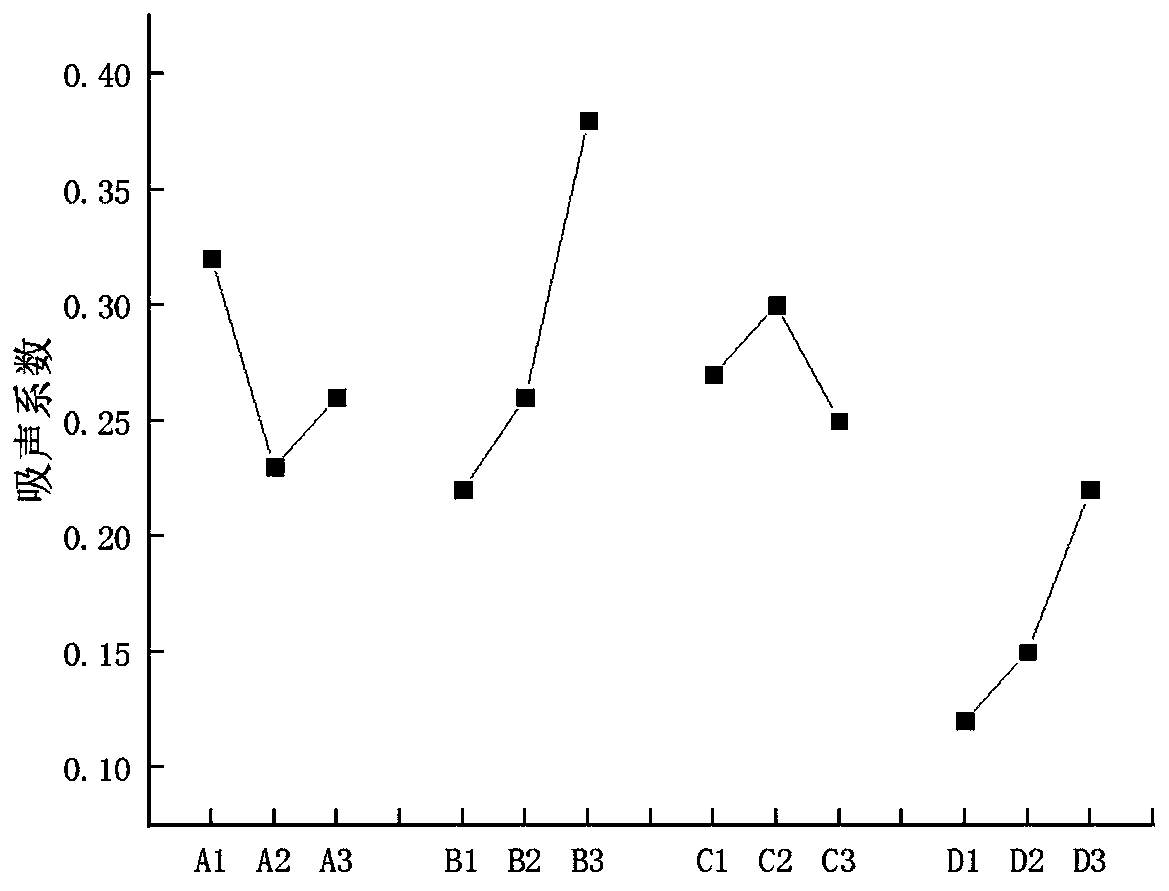

[0065] The dosage of described expanded perlite, the dosage of rice husk ash and the dosage of terminal hydroxyl polyepichlorohydrin are divided into three groups: in the first group, the dosage of expanded perlite is 5% of the polyure...

Embodiment 3

[0069] Preparation of Modified Polyurethane Foam

[0070] Mix polyurethane black material, polyurethane white material, expanded perlite, and rice husk ash according to the ratio under stirring at 250 rpm to obtain a polyurethane foam prepolymer, and then make the polyurethane foam prepolymer polyurethane foam prepolymer Pour the body into the mold, let it stand at room temperature for 10 minutes, then add the hydroxyl-terminated polyepichlorohydrin solution, then place it in an oven at 110°C for 24 hours, demould to obtain a sample, and mature the sample for 24 hours at room temperature to obtain the modified polyurethane foam. bubble body.

[0071] The mass ratio of the polyurethane black material and the polyurethane white material is 6:4.

[0072] The amount of expanded perlite and the amount of rice husk ash are divided into three groups: the amount of expanded perlite in the first group is 5% of the quality of the polyurethane foam material, and the amount of rice husk ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com