Preparation method for composite sound absorption material

A technology of sound-absorbing materials and raw materials, which is applied in the field of preparation of composite sound-absorbing materials, can solve the problems of poor sound-absorbing effect of sound-absorbing materials, and achieve the effect of good sound insulation effect and good void ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

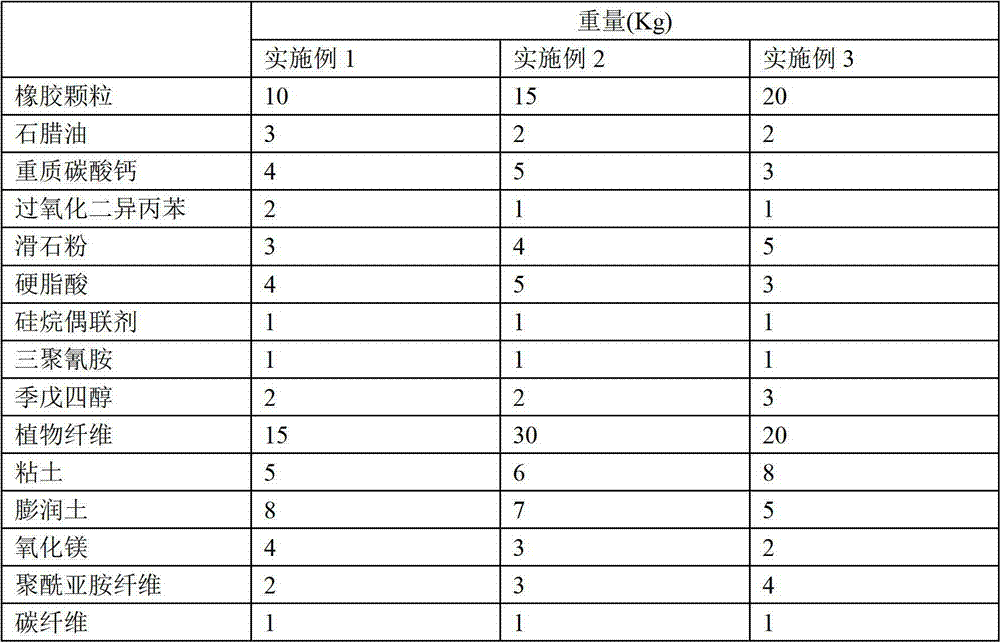

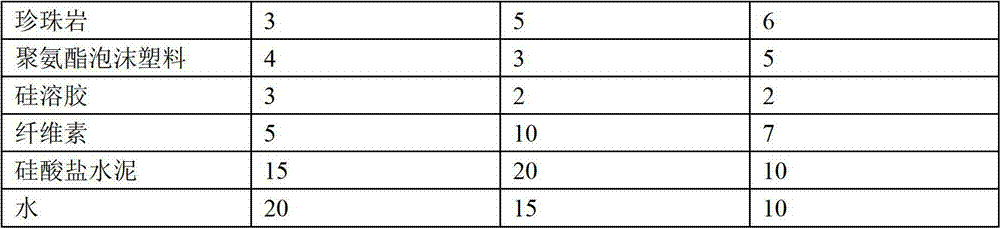

Embodiment 1

[0024] The preparation method is:

[0025] S1: Take rubber particles, paraffin oil, heavy calcium carbonate, dicumyl peroxide, talcum powder, stearic acid, silane coupling agent, melamine, and pentaerythritol, and mix them uniformly at a temperature of 90°C;

[0026] S2: Send the mixture obtained in step S1 into an extruder, and extrude at a temperature of 120°C; granulate;

[0027] S3: Mix the particles obtained in S2 with plant fiber, clay, bentonite, magnesium oxide, polyimide fiber, carbon fiber, perlite, polyurethane foam, silica sol, and cellulose;

[0028] S4: Add cement and water to the mixture obtained in S3, stir evenly, pour it into a mold, solidify and form it, and obtain a finished product.

[0029] The particle size of the granulation in S4 is preferably 1-2 mm.

Embodiment 2

[0031] The difference between the preparation method and Example 1 is that the temperature in the S1 step is 95°C, and the temperature in the S2 step is 125°C.

Embodiment 3

[0033] The difference between the preparation method and Example 1 is that the temperature in the S1 step is 100°C, and the temperature in the S2 step is 130°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com