Railway Traction Transformer High Voltage Switchgear

A high-voltage switch and railway traction technology, which is applied in the setting of switchgear, switchgear, board/panel/desk of substation/switchgear, etc., can solve the problems of large volume, gas leakage and low safety of gas-insulated switchgear, etc. Achieve the effect of improving operational safety, improving reliability and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

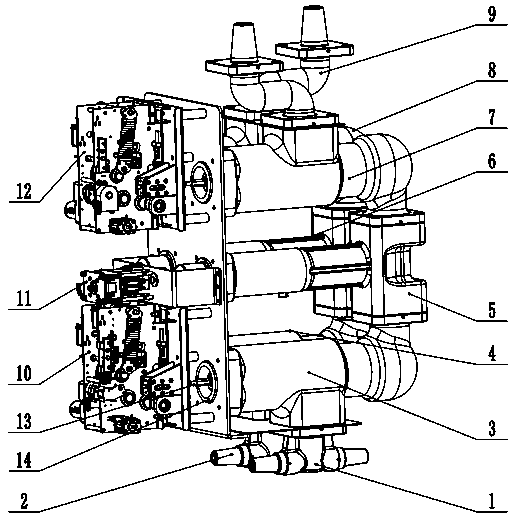

[0016] attached figure 1 For ease of illustration, housing parts have been removed. as attached figure 1 As shown, a railway traction transformer high-voltage switchgear includes a main incoming circuit breaker 3, a backup incoming circuit breaker 4, a main grounding switch 5, a backup grounding switch 6, a main bus circuit breaker 7, a backup bus circuit breaker 8, a main Incoming line bushing 1, spare incoming line bushing 2, busbar bushing 9, incoming circuit breaker operating mechanism 10, grounding switch operating mechanism 11, and busbar circuit breaker operating mechanism 12. The circuit breaker consists of a vacuum interrupter, copper conductors and solid insulation. The grounding switch can use a vacuum interrupter or an air switch. The non-connecting part on the surface of the solid insulating material is solidified with a semi-conductive shielding layer and connected to the shell. There are pressure equalizing parts at the connection of conductors to eliminate ...

Embodiment 2

[0023] The solid insulating material is epoxy resin. The pressure equalizer is made of 0.5 mm thick stainless steel mesh.

[0024] All the other are with embodiment 1.

Embodiment 3

[0026] The solid insulating material is EPDM rubber. The pressure equalizing part is made of carbon fiber through mold processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com