Air Self-Breathing Membraneless Microfluidic Fuel Cell with Integral Cylindrical Anode

A fuel cell and self-breathing technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as large fuel evaporation chamber, short residence time, and limited reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

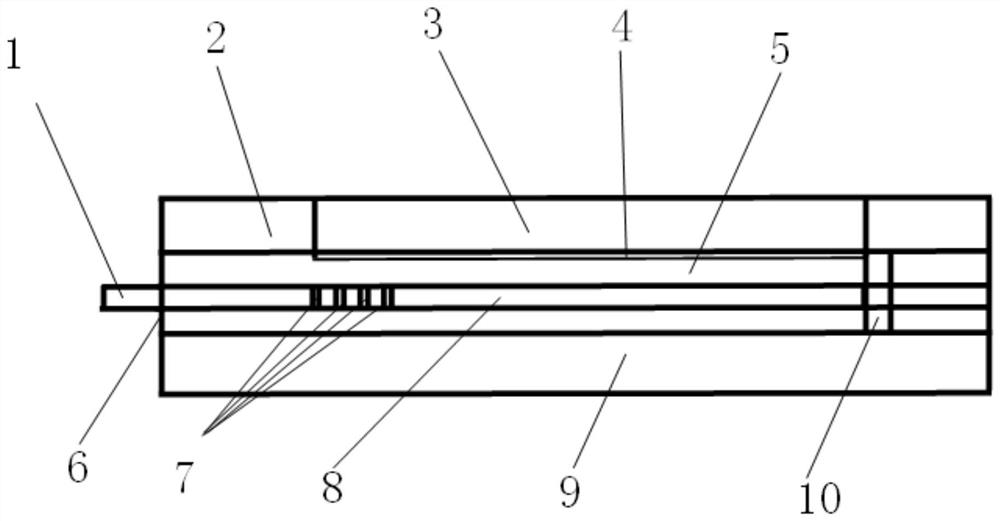

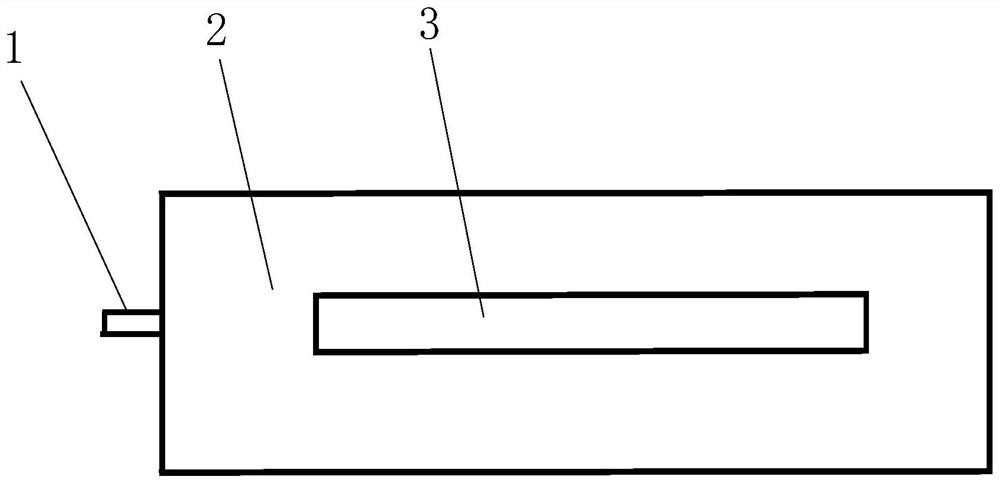

[0026] see Figure 1 to Figure 4, an air self-breathing membraneless microfluidic fuel cell with an integral cylindrical anode, comprising a membraneless microfluidic fuel cell main body, the membraneless microfluidic fuel cell main body comprising a cathode cover plate 2, an air self-breathing cathode 4, a flow Channel 5, cylindrical anode 8 and battery bottom plate 9, the cathode cover plate, flow channel and battery bottom plate 9 are all made of plastic; the cathode cover plate 2 is provided with a cathode air breathing hole 3, and the cathode air breathing hole 3 is arranged on Air is self-breathing above the cathode 4; the flow channel 5 is arranged between the cathode cover plate 2 and the battery bottom plate 9; the front end of the flow channel 5 is provided with an electrolyte inlet 6, and a metal round tube 1 is arranged in the flow channel 5; The outer surface of the metal round tube 1 is coated with a Pd / Nafion catalytic layer by repeated electrochemical depositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com