Preparation method of multi-color electrochromic thin film with tin dioxide/vanadium pentoxide core-shell structure

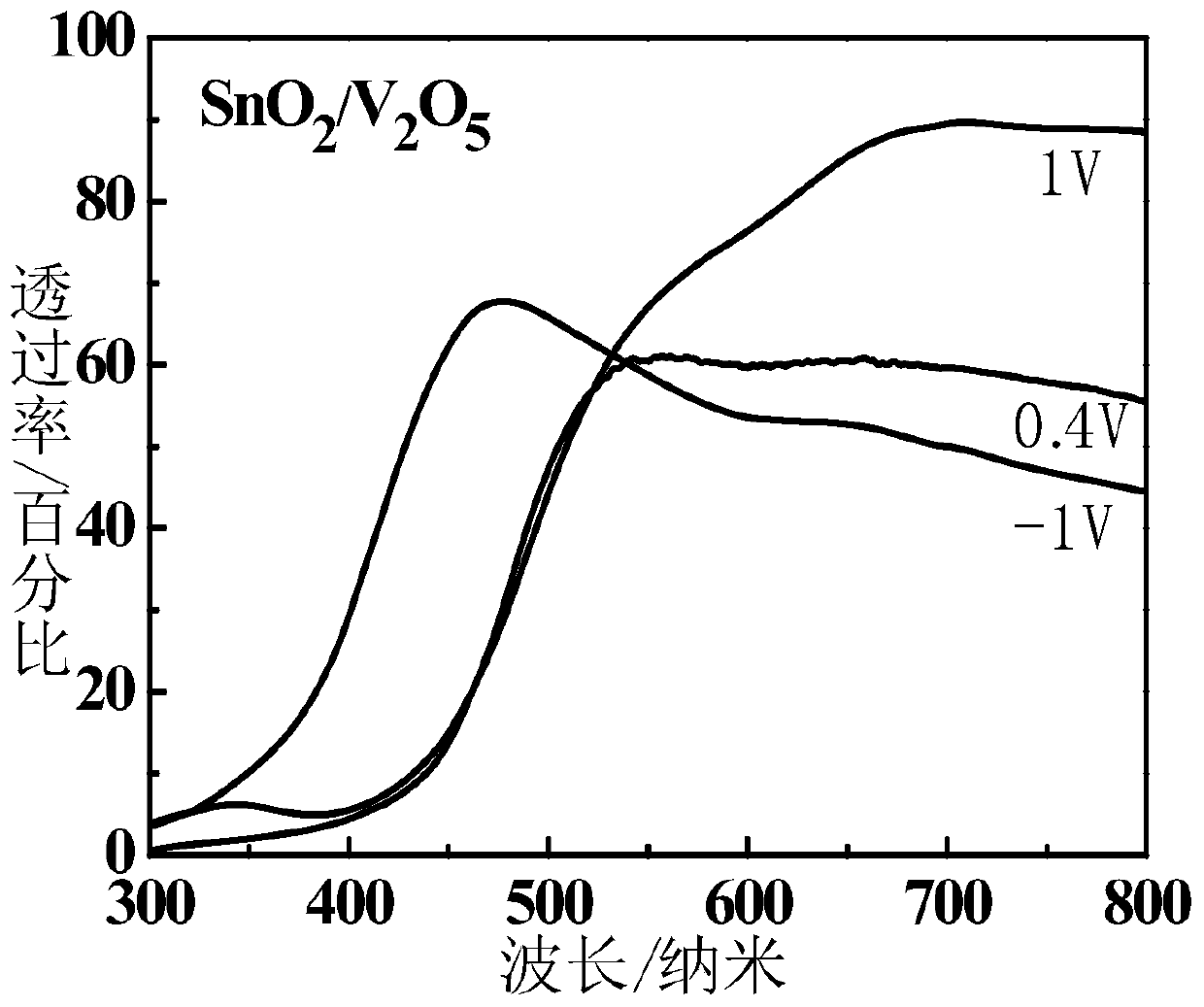

A technology of vanadium pentoxide and tin dioxide, which is applied in the field of preparation of multi-color electrochromic thin films, can solve the problems of low conductivity and ion diffusion coefficient, low coloring efficiency, poor cycle reversibility and stability, and achieve good Implementability, improved stability, and accelerated reaction kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

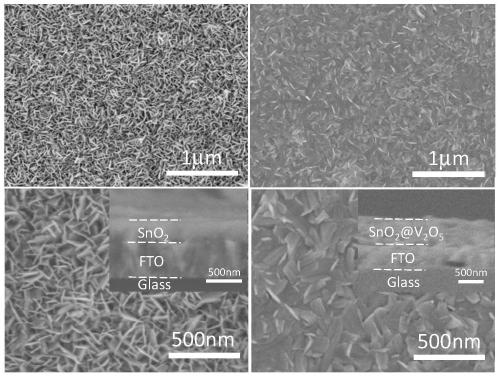

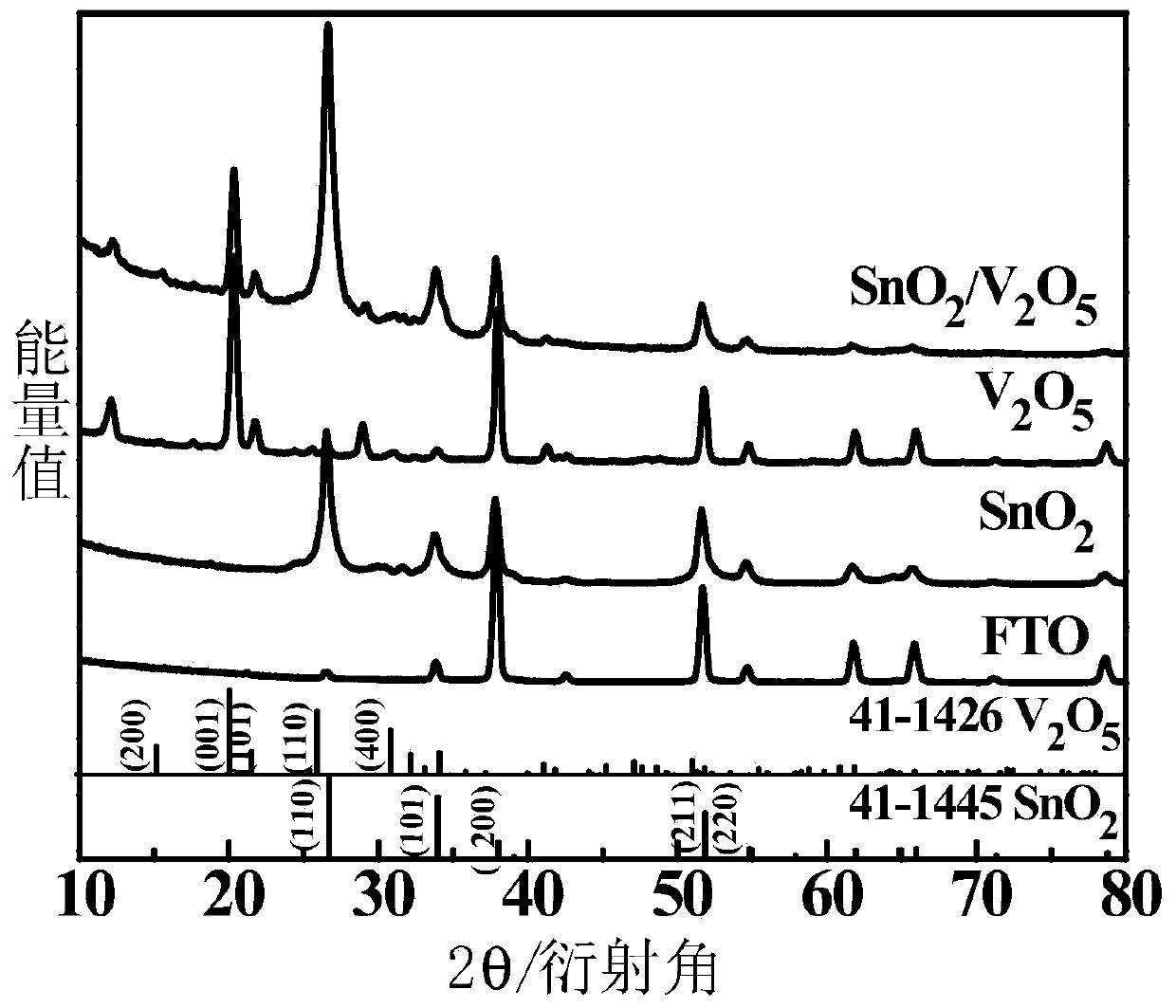

[0039] Preparation of multicolor electrochromic film with tin dioxide / vanadium pentoxide core-shell structure:

[0040] (1) FTO conductive glass (produced by Shenzhen Huanan Xiangcheng Technology Co., Ltd.) was ultrasonically cleaned in deionized water for 20 minutes, then dried in an oven at 60°C, and treated in a plasma cleaning machine for 5 minutes before use;

[0041] (2) Dissolve 1g urea, 1mL (37wt%) hydrochloric acid, and 20μL thioglycolic acid in 80mL deionized water successively, stir for 5 minutes, then add 0.2g of stannous chloride dihydrate to it, and stir for 10 minutes to form a uniform The precursor solution;

[0042] (3) The precursor solution in step (2) is added to the autoclave, and the conductive substrate is placed obliquely and immersed in the precursor solution with the FTO conductive surface facing down. Hydrothermal reaction was carried out in an oven at 120℃ for 6h. After the reaction was completed, the water was cooled to room temperature 25℃. The sample w...

Embodiment 2

[0047] Preparation of multicolor electrochromic film with tin dioxide / vanadium pentoxide core-shell structure:

[0048] (1) FTO conductive glass (produced by Shenzhen Huanan Xiangcheng Technology Co., Ltd.) was ultrasonically cleaned in deionized water for 20 minutes, then dried in an oven at 60°C, and treated in a plasma cleaner for 5 minutes before use:

[0049] (2) Dissolve 1g urea, 1mL (37wt%) hydrochloric acid, and 20μL thioglycolic acid in 80mL deionized water successively, stir for 5 minutes, then add 0.2g of stannous chloride dihydrate to it, and stir for 10 minutes to form a uniform The precursor solution;

[0050] (3) The precursor solution in step (2) is added to the autoclave, and the conductive substrate is placed obliquely and immersed in the precursor solution with the FTO conductive surface facing down. Hydrothermal reaction was carried out in an oven at 120℃ for 6h. After the reaction was completed, the water was cooled to room temperature 25℃. The sample was taken ...

Embodiment 3

[0055] Preparation of multicolor electrochromic film with tin dioxide / vanadium pentoxide core-shell structure:

[0056] (1) The conductive carbon cloth film was ultrasonically cleaned in deionized water for 20 minutes, then dried in an oven at 60°C, and treated in a plasma cleaner for 5 minutes before use:

[0057] (2) Dissolve 1g urea, 1mL (37wt%) hydrochloric acid, and 20μL thioglycolic acid in 80mL deionized water successively, stir for 5 minutes, then add 0.2g of stannous chloride dihydrate to it, and stir for 10 minutes to form a uniform The precursor solution;

[0058] (3) The precursor solution in step (2) is added to the autoclave, and the conductive substrate is placed obliquely and immersed in the precursor solution with the FTO conductive surface facing down. Hydrothermal reaction was carried out in an oven at 120℃ for 6h. After the reaction was completed, the water was cooled to room temperature 25℃. The sample was taken out, rinsed and dried overnight, and heat treated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com