A kind of preparation method of phosphorus organosilicon type flame retardant

A technology of organosilicon and flame retardants, which is applied in the field of preparation of phosphorus-based organosilicon flame retardants, can solve the problems of affecting the physical properties of materials, poor use effects, and poor flame retardant properties, and achieves obvious flame retardant effects, Low cost and improved physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

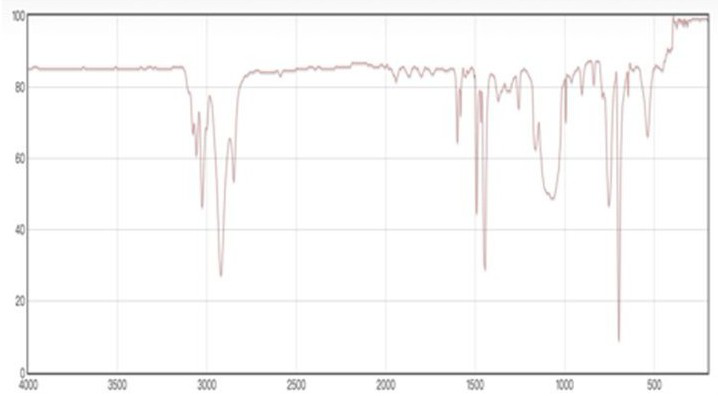

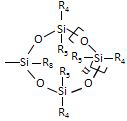

Image

Examples

Embodiment 1

[0020] A preparation method of a phosphorus-based organosilicon type flame retardant is carried out according to the following scheme:

[0021] In terms of parts by mass, 20 parts of p-aminophenyldimethoxysilane, 35 parts of diethoxysilane and 100 parts of toluene, 0.03 parts of tris[N,N-bis(trimethylsilane)amine] Add erbium into the pressure reactor, control the temperature at 50°C, stir for 35 minutes, then pump inert gas through the reactor for 3 times after vacuuming, and add 1.5 parts of water and 2.5 parts of porous boron-containing organic base solid catalyst to the reaction kettle after removing the air. In the kettle, stir and heat up to 70°C, keep warm for 24 hours; after the reaction is completed, heat up to 113°C, use a water separator to separate the water, and then slowly add 40 parts of toluene solution containing 5.8 parts of phosphorus oxychloride to the reaction kettle , then add 0.01 part of tetramethylguanidine perfluoroethane sulfonate, control the tempera...

Embodiment 2

[0027] A preparation method of a phosphorus-based organosilicon type flame retardant is carried out according to the following scheme:

[0028] In terms of parts by mass, 10 parts of p-aminophenyldimethoxysilane, 30 parts of diethoxysilane and 80 parts of toluene, 0.01 part of tris[N,N-bis(trimethylsilane)amine] Add erbium into the pressure reactor, control the temperature at 40°C, stir for 30 minutes, then pump inert gas through the reactor for 3 times after vacuuming, and add 0.5 parts of water and 0.1 part of porous boron-containing organic base solid catalyst to the reaction kettle after removing the air. In the kettle, stir and raise the temperature to 60°C, keep the temperature for 18h; after completing the reaction, raise the temperature to 110°C, use a water separator to separate the water, and then slowly add 20 parts of toluene solution containing 3.5 parts of phosphorus oxychloride to the reaction kettle , then add 0.06 part of tetramethylguanidine perfluoroethane s...

Embodiment 3

[0034]A preparation method of a phosphorus-based organosilicon type flame retardant is carried out according to the following scheme:

[0035] According to the number of parts by mass, 30 parts of p-aminophenyldimethoxysilane, 40 parts of diethoxysilane and 120 parts of toluene, 0.06 parts of tris[N,N-bis(trimethylsilane)amine] Add erbium into the pressure reactor, control the temperature at 60°C, stir for 40 minutes, then pump inert gas through the reactor for 3 times after vacuuming, and add 3.5 parts of water and 5 parts of porous boron-containing organic base solid catalyst to the reaction kettle after removing the air. In the kettle, stir and heat up to 80°C, keep the temperature for 30h; after completing the reaction, heat up to 115°C, use a water separator to separate the water, and then slowly add 50 parts of toluene solution containing 10.6 parts of phosphorus oxychloride to the reaction kettle , then add 0.06 part of tetramethylguanidine perfluoroethane sulfonate, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com