Intensive treatment method and system for complex high-concentration organic ammonia-nitrogen wastewater

A technology for the enhanced treatment of ammonia nitrogen wastewater, which is applied in the field of environmental engineering and can solve problems such as difficult treatment, slow effect, and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

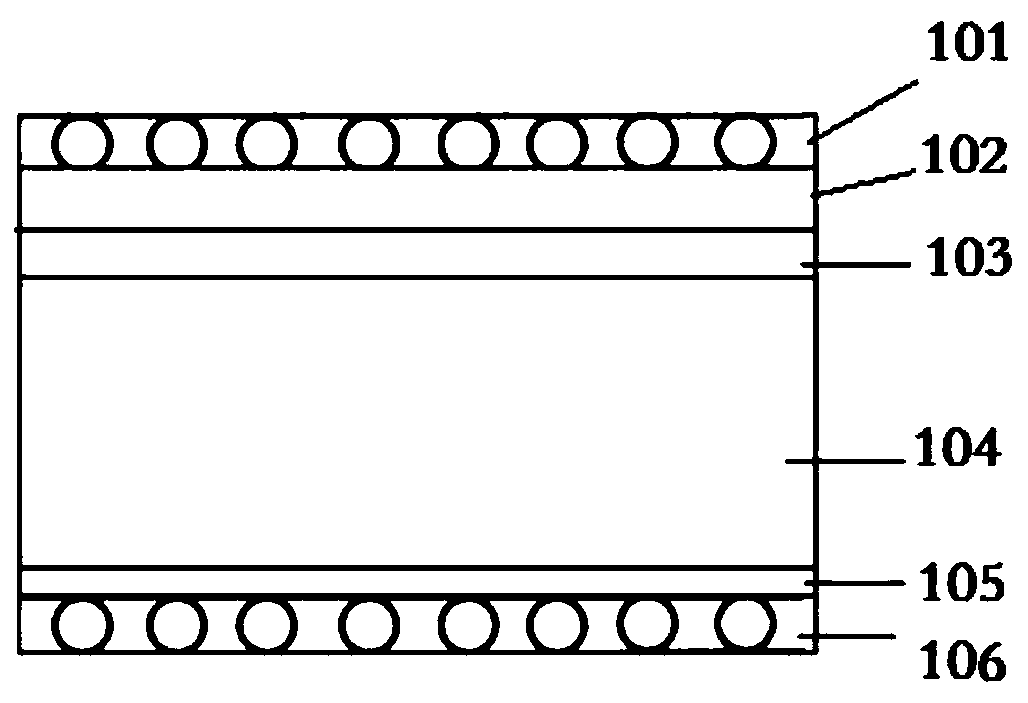

[0062] GY-4 type packing matrix, the preparation process is as follows:

[0063]1) Select the landfill that has been buried for 5 to 40 years, and after removing stones, broken glass, incompletely degraded rubber and plastic, wooden sticks, paper and other debris with particles larger than 10mm, the moisture content is 20 to 36%. mineralized waste; the abundances of Pseudomonas, Sphingomonas, Comamonadaceae and Hyphomicrobiaceae in the mineralized waste were as high as 12.73%, 12.29%, and 8.82% respectively. % and 6.40%.

[0064] 2) Choose an ellipsoid, with a particle size of 6-13mm and a bulk density of 0.9-1.5g / cm 3 , ceramsite with a porosity of 0.3-0.7;

[0065] 3) Mix the mineralized waste and ceramsite at a mass ratio of 1: (3~7), soak and stir in the nitrifying bacteria culture medium for 150 seconds, and mix well; every two days, replace with fresh nitrifying bacteria culture medium and mix well After culturing for 10 days, the primary packing matrix is completed...

Embodiment 2

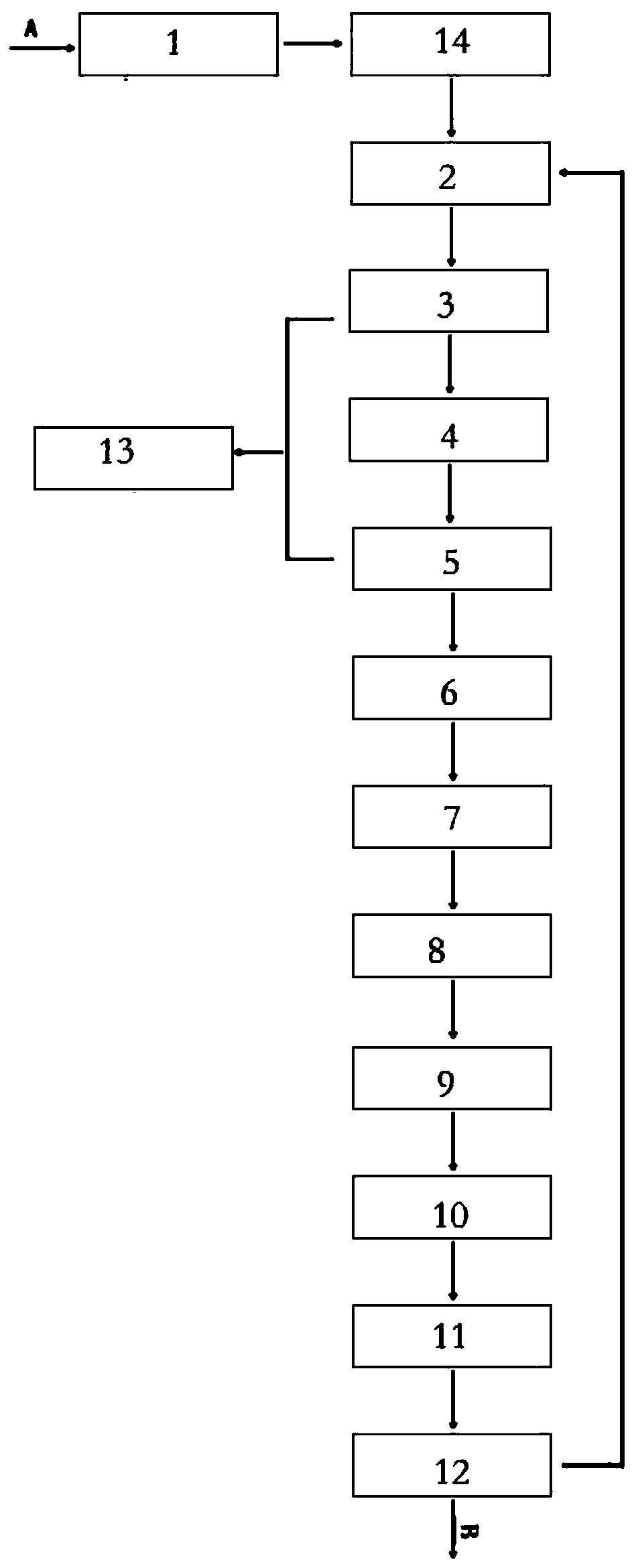

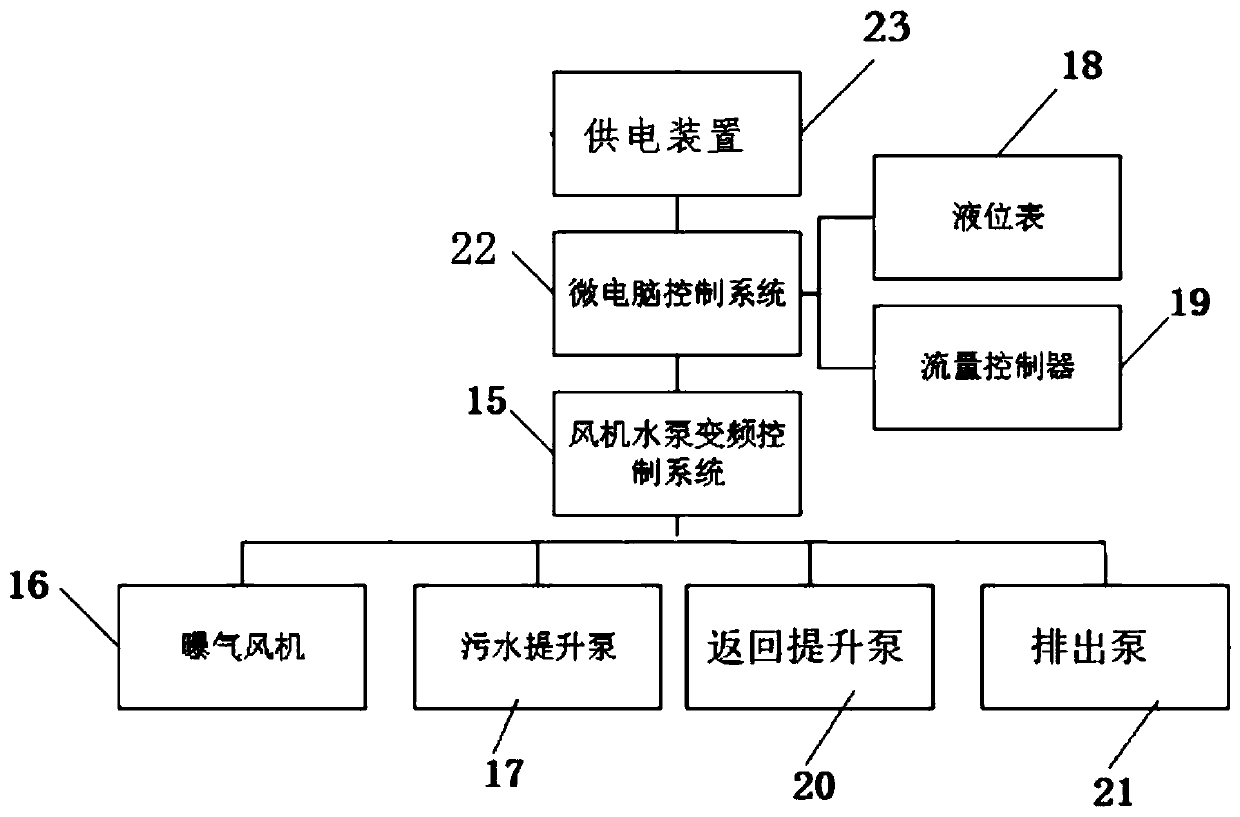

[0068] An enhanced treatment system for complex and high-concentration organic ammonia nitrogen wastewater, including water collection adjustment tank 1, grease trap 14, coagulation reaction tank 2, inclined tube sedimentation tank 3, Fenton reaction tank 4, air flotation device 5, biochemical adjustment tank 6 , A / O biochemical pool 7, MBR membrane pool 8, ultrafiltration system 9, co-position nitrification and denitrification filter bed 10, reverse osmosis system 11 and discharge pool 12 are connected in sequence, and the treatment system also includes: power supply device 23; microcomputer control System 22, the first end of the microcomputer control system 22 is electrically connected to the power supply device 23; the fan water pump frequency conversion control system 15, the first end of the fan water pump frequency conversion control system 15 is connected to the first end of the microcomputer control system 22 The two ends are electrically connected; the aeration fan 16...

Embodiment 3

[0076] The water quality of the leachate produced by a garbage dump in Wannian County, Jiangxi Province is shown in Table 1, and the scale of sewage treatment is 150m 3 / d. The garbage leachate produced in the garbage landfill area flows into the water collection adjustment tank through the special collection pipe through the mechanical grid, and then is processed by the process of the present invention. Compared with the traditional process, the treatment effect of the present invention is shown in Table 2. The main water quality indicators have all reached the limit values specified in GB16889-2008 "Standards for Pollution Control of Domestic Garbage Landfill Sites". Processing costs.

[0077] Table 1: Wannian landfill leachate water quality unit: mg / L (except pH)

[0078] project parameters

[0079] Table 2 adopts the actual effect of a landfill leachate treatment project based on the present invention in Wannian

[0080] index

[0081] Explanation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com