A kind of transparent conductive silver mesh film and preparation method thereof

A transparent conductive and thin film preparation technology, which is applied in the manufacture of cables/conductors, conductive layers on insulating carriers, circuits, etc., can solve the problem of large grid structure roughness of transparent conductive films, easy aggregation of nanowires into bundles, and low dispersion and other problems, to achieve the effect of low cost, simple and environmentally friendly method, and eliminate seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

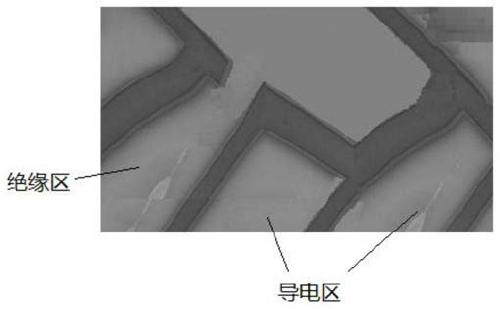

[0040] The present invention also provides a method for preparing a transparent conductive silver grid film using the particle-free silver ink, the film preparation method specifically comprising the following steps:

[0041] S1: Select the cracking liquid, and take an appropriate amount to coat it on the substrate, and control the temperature conditions to obtain the cracked plate.

[0042] The selected cracking fluid needs to have the characteristics of easy cracking after certain treatment, such as acrylic resin CA-600 emulsion, titanium dioxide sol, silica sol, crack nail polish, egg white and ice template, etc.

[0043] The substrate can be glass, polyethylene terephthalate (PET), polyimide (PI), polydimethylsiloxane (PDMS), photo paper substrate and the like.

[0044]In step S1, the appropriate amount of cracking solution is 20-100 μL.

[0045] In step S1, the coating treatment of the cracking liquid on the surface of the substrate may be drop coating, spin coating, spr...

Embodiment 1

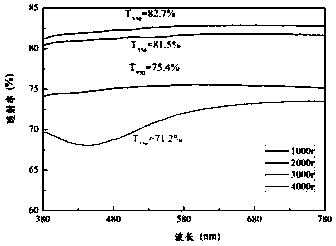

[0064] In this embodiment, the untreated water-soluble acrylic resin CA-600 emulsion is used as the cracking solution, and 50 μL of the acrylic resin CA-600 emulsion is spin-coated on the glass substrate. During the spin-coating process, the spin-coating parameters are set as The uniform coating speed is 500rpm, the uniform coating time is 15s, the spin coating speed is 1000-5000rpm, and the spin coating time is 20s. After heating at a heating rate of 200°C / h, keep it at 200°C for 1h to obtain the following: figure 2 The morphology of the cracked plate under different rotational speed conditions is shown, from figure 2 It can be seen from the morphology of the cracked plate formed by the cracking liquid under different rotating speed conditions: with the increase of the spin coating speed, the line width of the cracked plate gradually becomes smaller, and the number of meshes becomes denser. exist figure 2 Among them, when the spin coating speed is 5000rpm, the template th...

Embodiment 2

[0069] In this example, 20 μL, 40 μL, 70 μL, and 80 μL of water-soluble acrylic resin CA-600 emulsion were used to make cracked plates, and the cracking solution was spin-coated on the glass substrate at a speed of 5000 rpm during the production process, and the spin-coating time was 20s. , dried at a final temperature of 250 °C for 1 h at a heating rate of 200 °C / h, and observed as Figure 5 The cross-sectional views of cracked plates with different thicknesses are shown, where the thicknesses of the cracked templates are 18 μm, 7 μm, 5 μm, and 3 μm. From Figure 5 It can be concluded that: by controlling the coating amount of the water-soluble acrylic resin CA-600 emulsion template, the thickness of the template can be controlled, and then the thickness of the obtained transparent conductive silver grid structure film can be controlled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com