Heat dissipation system for high-frequency high voltage power supply

A high-frequency high-voltage power supply and heat dissipation system technology, which is applied in the direction of transformer/inductor cooling, cooling/ventilation/heating transformation, etc., can solve the problems of polluting electronic components, transformer oil leakage, poor heat dissipation, etc., and achieve energy saving , prevent seepage, reduce the effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

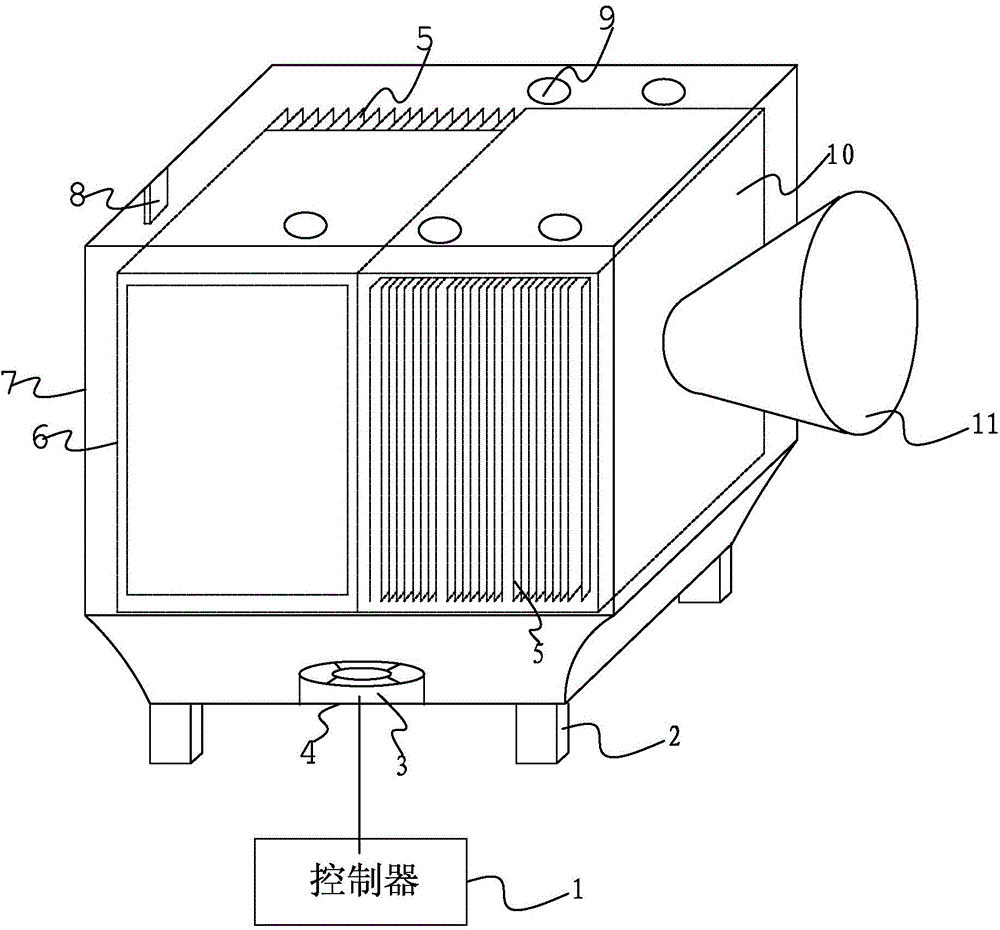

[0019] like figure 1 The heat dissipation system shown for high-frequency high-voltage power supply is applied to high-frequency high-voltage power supply. The high-frequency high-voltage power supply includes a casing, a fuel tank 10 and an inverter box placed in the casing; a high-voltage power supply is placed inside the fuel tank 10 Transformer; characterized in that it includes: a fan 3 installed on the bottom surface of the casing; an air inlet 4 arranged on the bottom surface of the casing corresponding to the position of the fan 3; a radiator 5 installed on the outer wall of the oil tank 10 and the inverter box; Inside the casing, a temperature sensor for monitoring temperature changes inside the casing; a plurality of cooling holes on the top of the casing; a detachable dust-proof net arranged outside the cooling holes; brackets 2 arranged at the four corners of the bottom of the casing; The input module used to receive the start-stop control command of the fan 3 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com