Liquid blocking device for direct-liquid type pen

A straight-liquid, liquid-blocking technology, used in writing instruments, ink pens with an ink storage tube in the pen, printing, etc., can solve the problem of easy overflow from the airflow channel into the liquid-blocker, etc., and achieves novel design and reasonable conception. , avoid wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

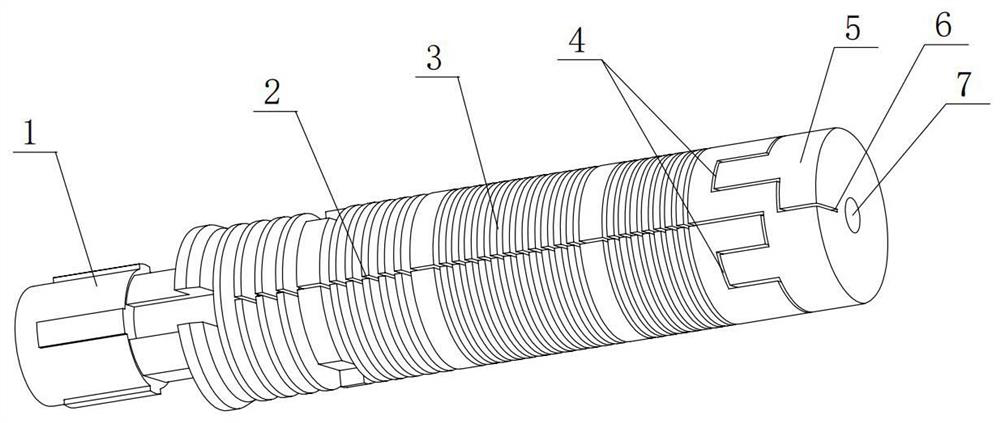

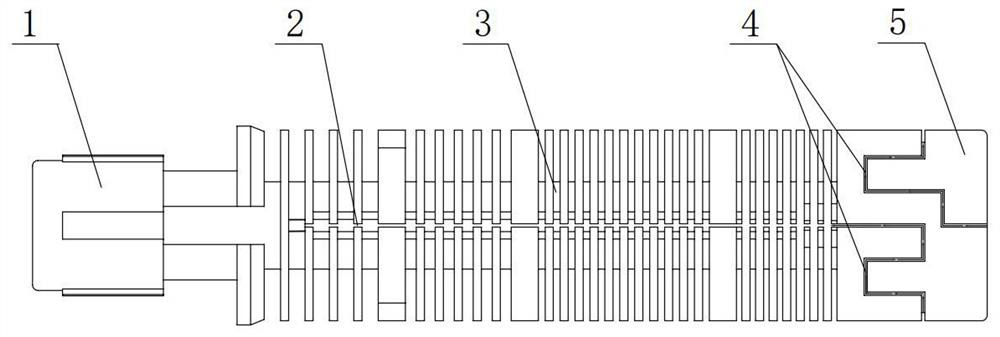

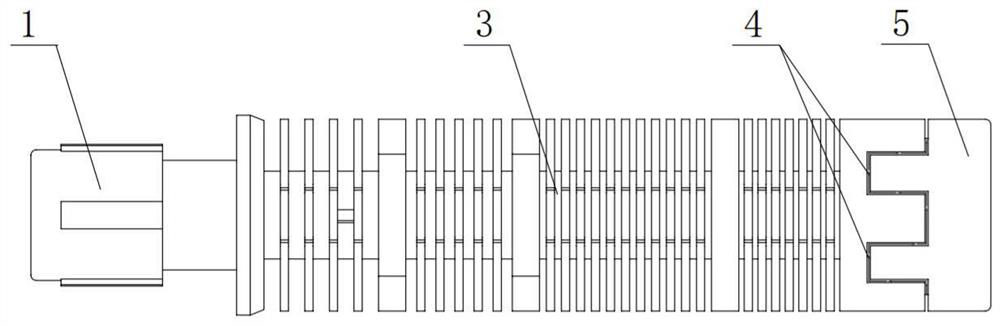

[0018] As shown in the figure, it is a straight liquid pen stopper, which is composed of the nib connecting end 1 at the front, the leaf grid group 3 at the middle, and the cylindrical seat 5 at the tail in sequence, and the nib connecting end 1 is used for Install the nib, the bottom surface of the cylindrical seat 5 cooperates with the ink tank 8, and the center of the bottom surface of the cylindrical seat 5 is provided with the water inlet hole 7 matched with the water outlet of the ink tank 8. When in use, the ink of the ink tank 8 enters the liquid blocking hole through the water inlet hole 7. The ink channel in the device reaches the nib; the leaf grid group 3 is longitudinally provided with a straight groove 2, and the cylindrical surface of the cylindrical seat 5 is matched with a zigzag groove 4, and the zigzag groove 4 is formed by at least two waves along the circumference. The direction is evenly distributed, and one end of the zigzag groove 4 is connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com