Cooling system used for high-frequency high-voltage power supply

A high-frequency high-voltage power supply and heat dissipation system technology, which is applied in the direction of temperature control by electric means, auxiliary controller with auxiliary heating device, etc., can solve the problems of wasting electric energy, high integration, small size, etc. Exudation, ensure normal operation, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

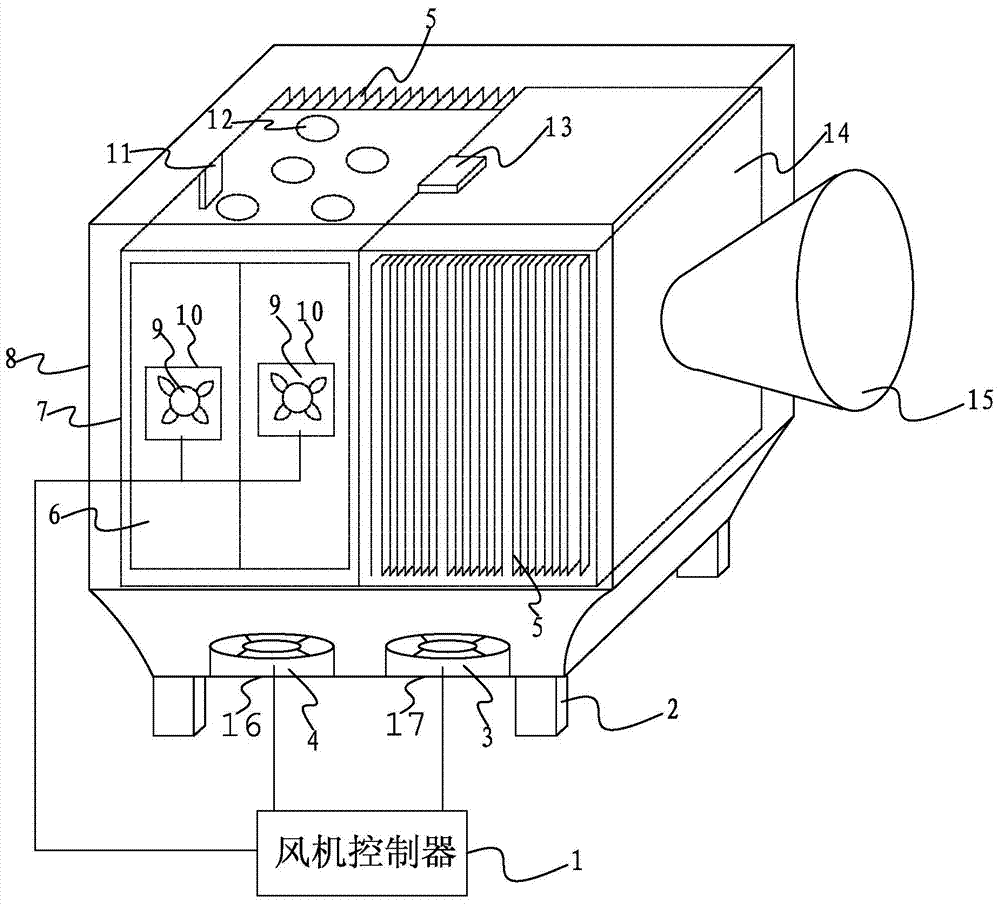

[0022] Such as figure 1 The heat dissipation system for a high-frequency high-voltage power supply shown is applied in a high-frequency high-voltage power supply. The high-frequency high-voltage power supply includes a casing 8, an oil tank 14 placed in the casing 8, and an inverter box 7; the inside of the fuel tank 14 A high-voltage transformer is placed; the side wall of the inverter box 7 is provided with an inverter box door 6, including: a first fan 3 and a second fan 4 installed on the bottom surface of the casing 8; The air inlet I17 corresponding to the position of the first fan 3; the air outlet 16 corresponding to the position of the second fan 4 arranged on the bottom surface of the casing 8; the radiator 5 installed on the outer wall of the oil tank 14 and the inverter box 7; installed on the oil tank 14 On the cover, the first temperature sensor 13 for monitoring the temperature change of the high-voltage transformer; installed in the inverter box 7, the second t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com