Preparation method of porous solid composite silk material

A composite wire, solid technology, applied in the direction of prosthesis, medical science, etc., can solve the problem of limiting wide application, and achieve the effect of simple process operation, firm combination and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

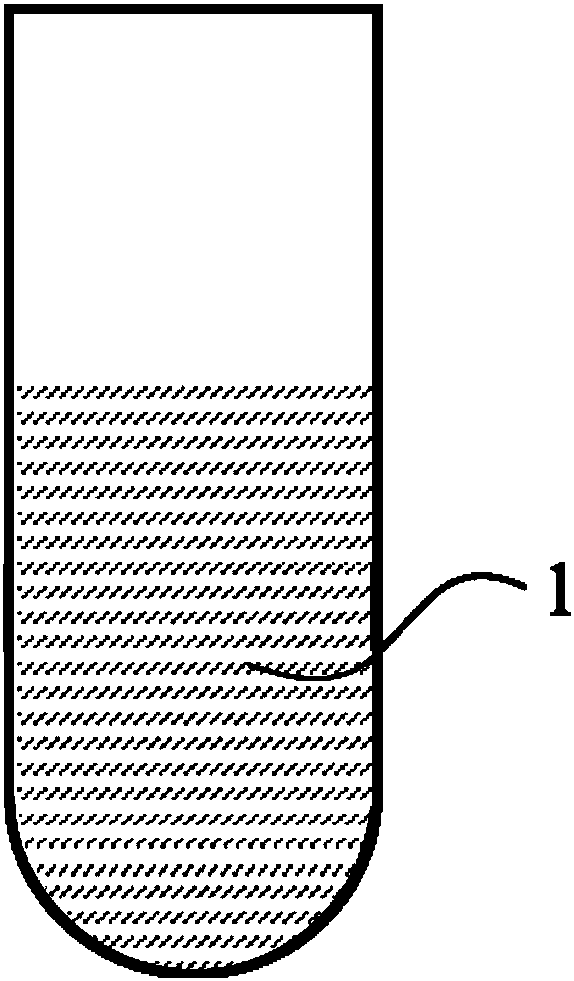

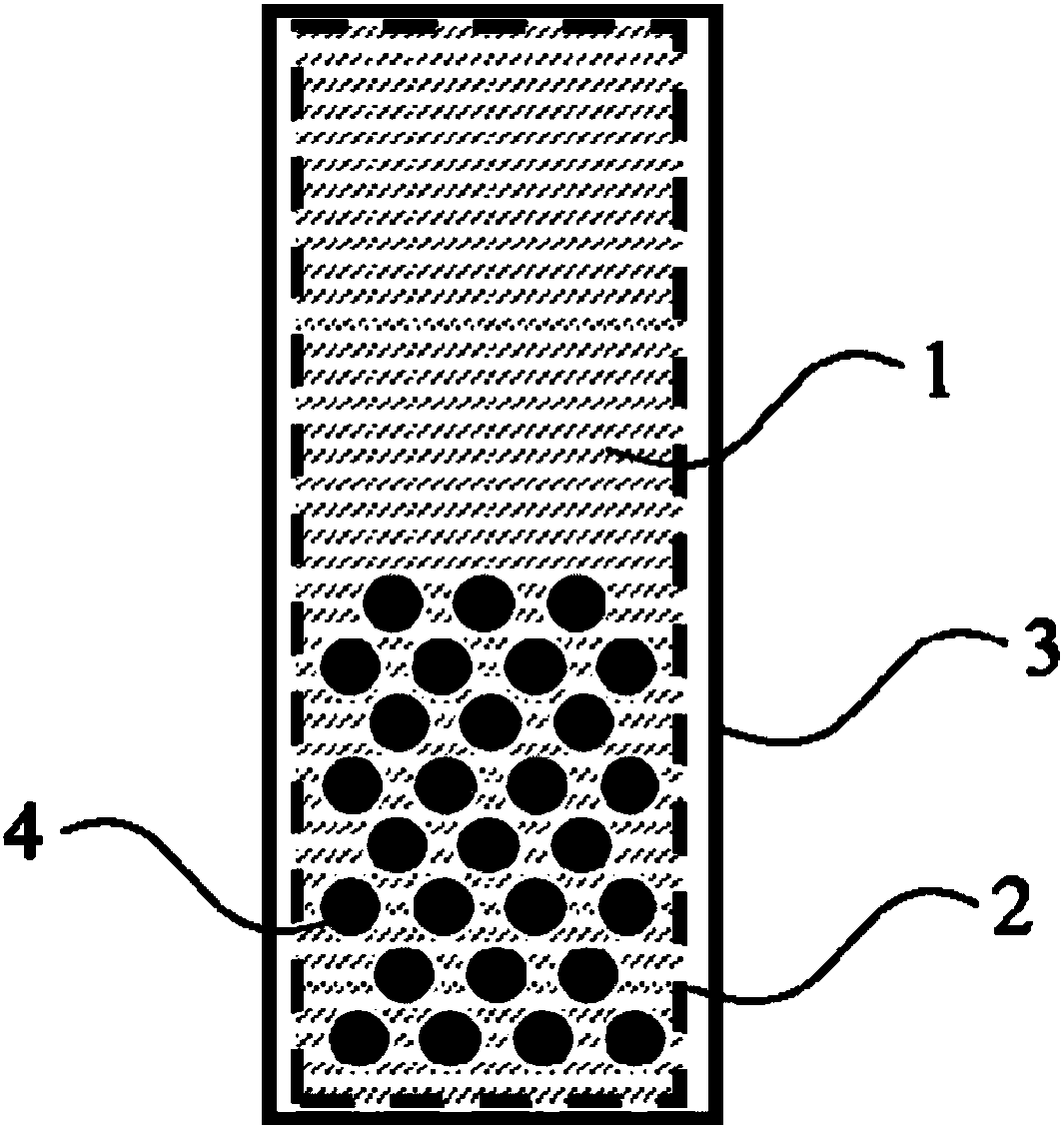

[0051] Embodiment 1 of the present invention provides a kind of porous-solid composite silk material preparation method, such as figure 1 As shown, the preparation method of the porous-solid composite silk material includes the following steps.

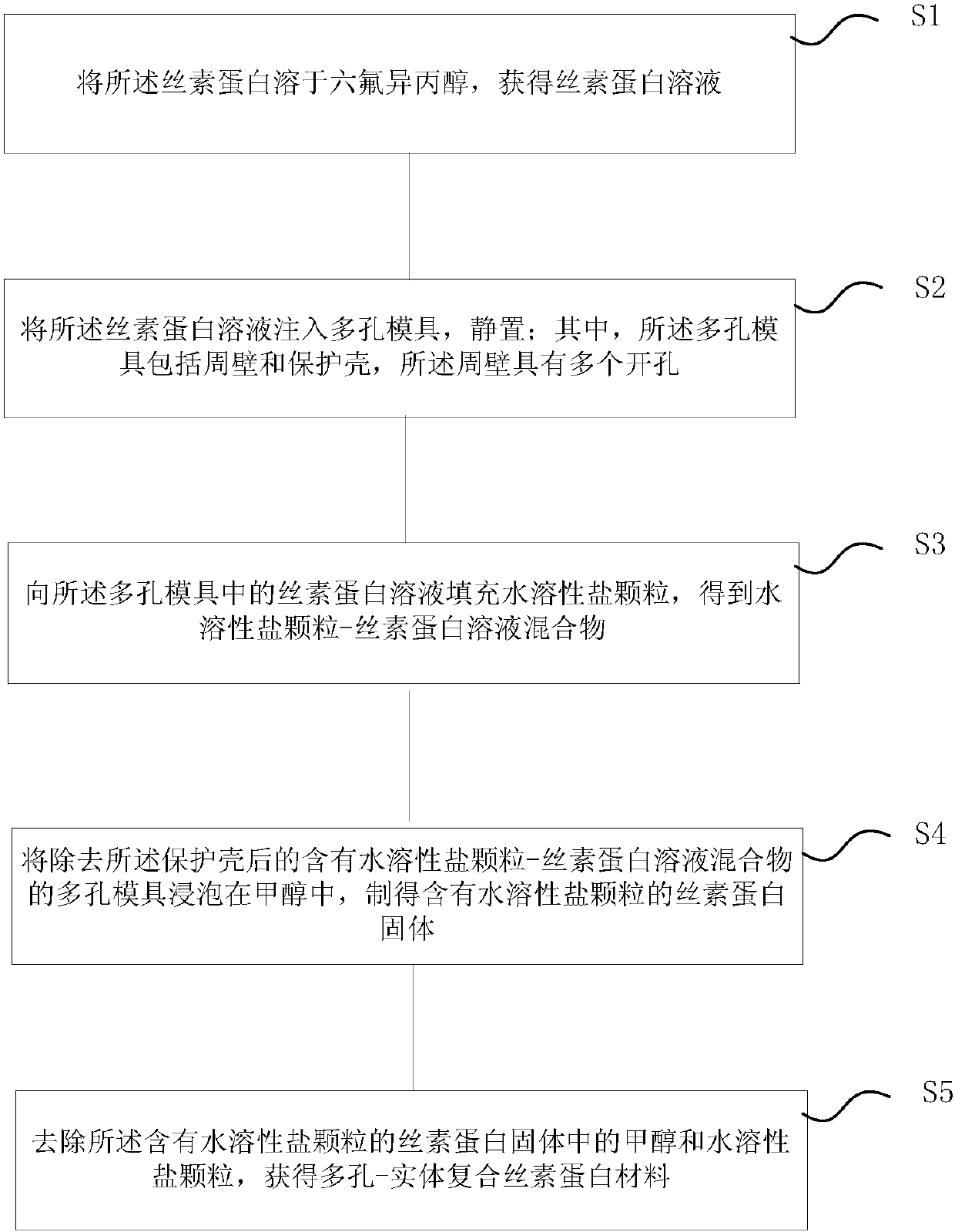

[0052] S1, the silk fibroin is dissolved in hexafluoroisopropanol to obtain the following figure 2 The silk fibroin solution 1 shown ( figure 2 1 in represents silk fibroin solution).

[0053] Specifically, each 10g cocoon was cut into pieces and placed in 4L of 2g / L sodium carbonate solution, heated to boil in an electric furnace and magnetically stirred at a speed of 200r / min, and the heating time was 60 minutes. Then, each portion of boiled silk is placed in 2L of ultrapure water, stirred, washed and kneaded dry, repeated 6 times, and then dried, the stirring speed is 200r / min, and the stirring time is 20min. The volume of ultrapure water changed each time is 2L, the drying method is 25°C and normal pressure (0.1MPa). Next, i...

Embodiment 2

[0071] In Example 2, the lithium bromide solution in S1 was replaced with a lithium thiocyanate solution, and other operations were the same as in Example 1.

[0072] The preparation method of the porous-solid composite silk material provided by the embodiment of the present invention provided in this example has simple process operation and is suitable for industrialization; the porous-solid composite silk material prepared by it has adjustable porosity and void diameter, porous structure and solid structure A porous-solid composite silk material that combines firmness, biodegradability, and adjustable mechanical properties.

Embodiment 3

[0074] In Example 3, the mass ratio of powdered silk fibroin to hexafluoroisopropanol is 1:1, and other operations are the same as in Example 1.

[0075] The preparation method of the porous-solid composite silk material provided by the embodiment of the present invention provided in this example has simple process operation and is suitable for industrialization; the porous-solid composite silk material prepared by it has adjustable porosity and void diameter, porous structure and solid structure A porous-solid composite silk material that combines firmness, biodegradability, and adjustable mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com