Degradable hollow fiber membrane and application thereof

A fiber membrane and hollow technology, which is applied to degradable hollow fiber membranes and their application fields to achieve the effects of good surface smoothness, good biocompatibility, and adjustable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

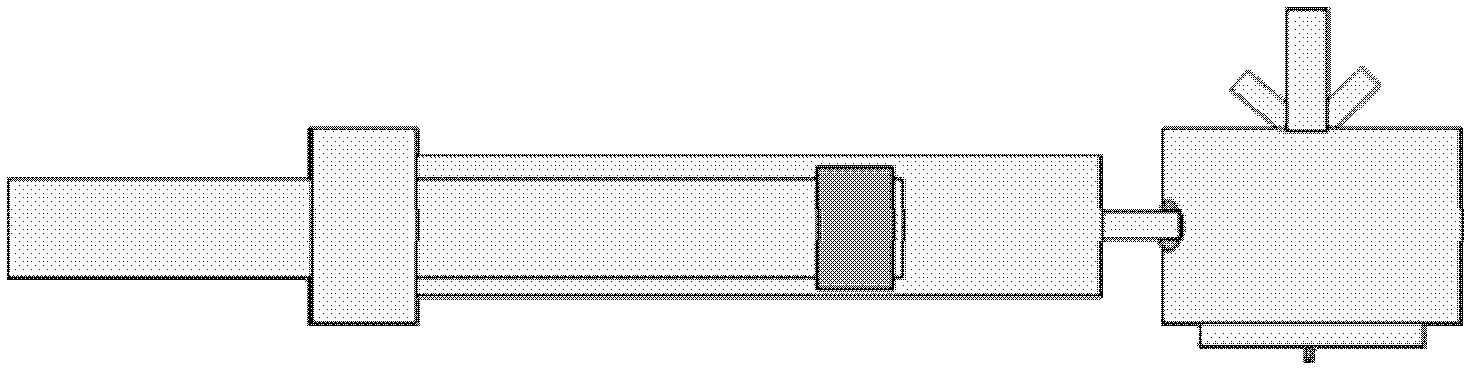

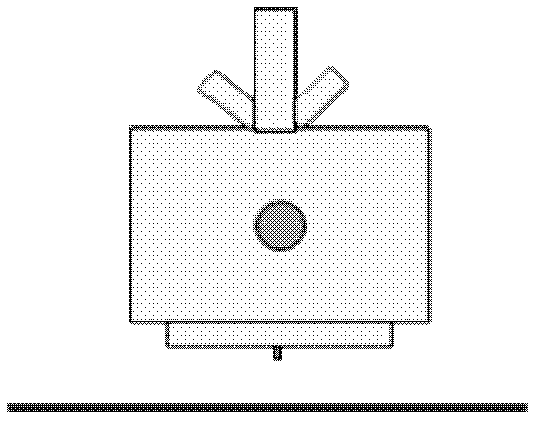

Image

Examples

Embodiment 1

[0038] (1) After pulverizing and drying polybutylene carbonate (PBC) with a molecular weight of 60,000, add polyethylene glycol (PEG) with a molecular weight of 8,000, and add the mixed raw materials to N,N-dimethylformamide , heated to 50°C, stirred and dissolved to form a solution, in which PBC accounted for 20% of the total mass, PEG accounted for 5% of the total mass, filtered the solution, and vacuum defoamed for 5 hours;

[0039] (2) Put the spinning solution into a barrel with heating and heat preservation function, keep the temperature at 50°C, extrude it with a spinneret for spinning hollow fibers, and solidify and shape it by wet spinning process. The parameters are: air layer Height 0cm, coagulation bath water, temperature 20°C; single-stage stretching, warm water bath as stretching medium, warm water bath temperature is 25°C, stretching ratio is 1.5 times; then remove solvent and porogen in warm water, in nitrogen Drying under protection, after sterilization treatm...

Embodiment 2

[0042] (1) After pulverizing and drying polybutylene carbonate (PBC) with a molecular weight of 100,000, add polyvinyl alcohol (PVA) with a molecular weight of 75,000, and add the mixed raw materials to N,N-dimethylformamide , heated to 40°C, stirred and dissolved to make a solution, in which PBC accounted for 25% of the total mass, and PVA accounted for 12% of the total mass, filtered the solution, and vacuum defoamed for 7h;

[0043](2) Put the spinning solution into a barrel with heating and heat preservation function, keep the temperature at 40°C, extrude it with a spinneret for spinning hollow fibers, and solidify and shape it by dry-wet spinning process. The parameters are: Air layer height 7cm, coagulation bath water, temperature 20°C; the stretching is carried out in two stages, the warm water bath is used as the stretching medium, the temperature of the warm water bath is 35°C, and the stretching ratio is 4 times; The pore agent is air-dried and sterilized to obtain t...

Embodiment 3

[0046] (1) After pulverizing and drying polybutylene carbonate (PBC) with a molecular weight of 150,000, adding sodium chloride micropowder with a diameter of 0.8 μm, adding the mixed raw materials into acetone, heating to 55°C, stirring and dissolving to prepare into a solution, in which PBC accounts for 25% of the total mass, sodium chloride micropowder accounts for 2% of the total mass, the solution is filtered, and vacuum degassed for 5 hours;

[0047] (2) Put the spinning solution into a barrel with heating and heat preservation function, keep the temperature at 50°C, extrude it with a spinneret for spinning hollow fibers, and solidify and shape it by wet spinning process. The parameters are: spinneret There is no air layer between the head and the coagulation bath, the coagulation bath water, the temperature is 10°C; the stretching is carried out in three stages, the warm water bath is used as the stretching medium, the temperature of the warm water bath is 30°C, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com