A kind of antibacterial oil-water separation nano-airgel composite material and its preparation method and application

A nano-aerogel and composite material technology is applied in the field of nano-aerogel composite materials for antibacterial oil-water separation and its preparation, which can solve the problems of loss of adsorption capacity, collapse of structure, and limited application of aerogels, and achieve a simple and convenient operation method. , The effect of short reaction time and few kinds of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

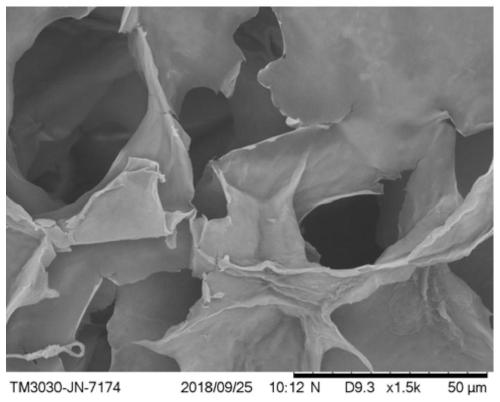

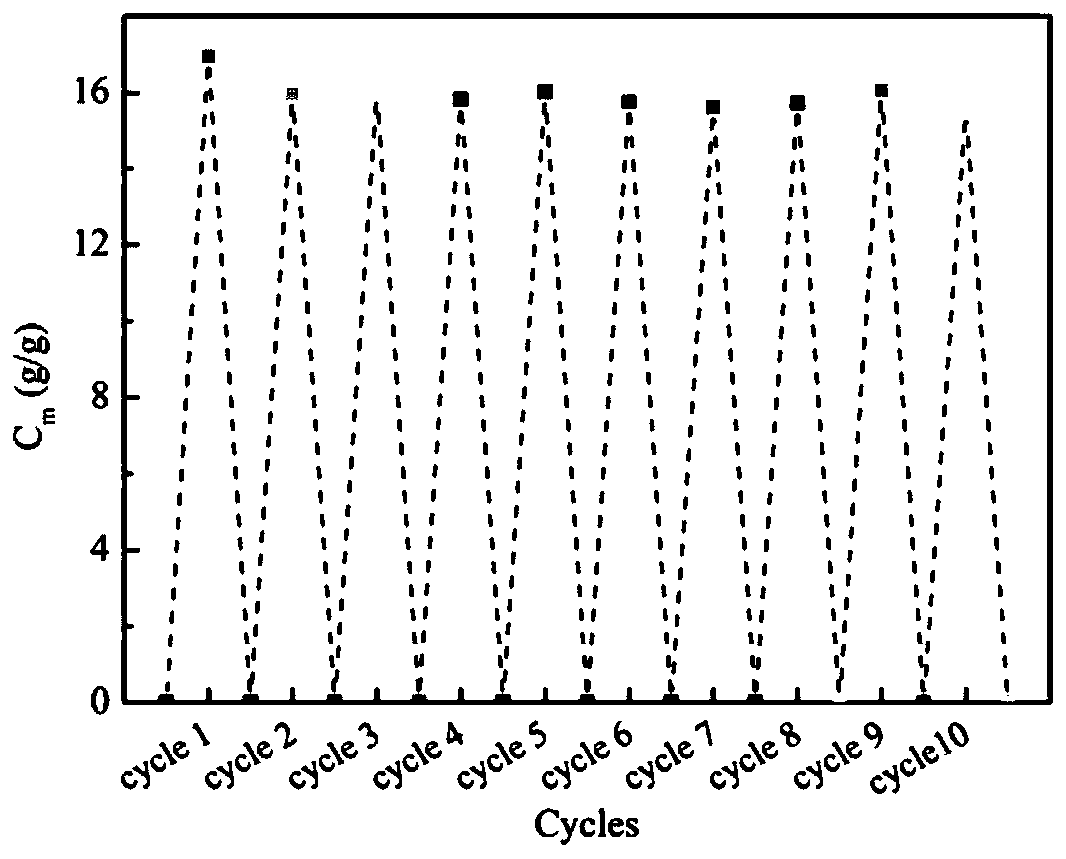

[0033] A nano-airgel composite material for antibacterial oil-water separation, the preparation method of which comprises the steps of:

[0034] (1) Add 1 g of nanocrystalline cellulose to 100 g of deionized aqueous solution, and ultrasonically disperse it into a homogeneous suspension with a mass fraction of 1 wt%, as Phase A;

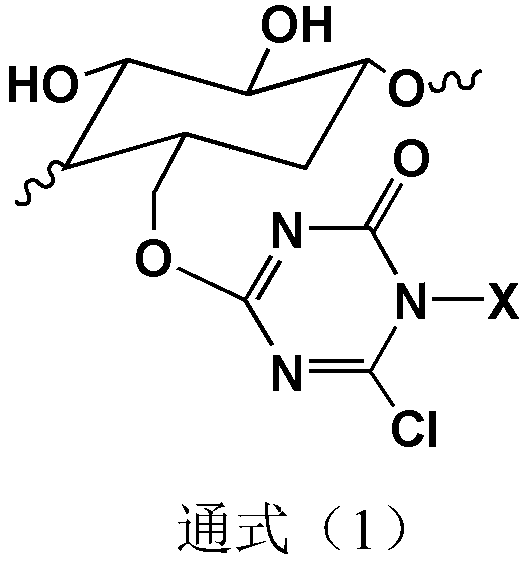

[0035] (2) Dissolve 2g of haloamine antibacterial agent precursor cyanuric chloride in 10ml of ethanol as phase B;

[0036] (3) At 0-5°C, use sodium bicarbonate solution to adjust the pH of Phase A to 8, slowly add Phase B to Phase A, keep stirring, and react for 1 hour. Centrifuge for 10 minutes, wash the obtained precipitate three times with deionized water, disperse the product in water, dialyze to neutrality with 8000 molecular weight dialysis bag, and then concentrate to a concentration of 2wt%, as phase C;

[0037] (4) Take 50 g of phase C, adjust the pH to 6 with sulfuric acid solution, raise the temperature to 60° C., slowly add 0.5 g of silo...

Embodiment 2

[0039] A nano-airgel composite material for antibacterial oil-water separation, the preparation method of which comprises the steps of:

[0040] (1) Add 3 g of nanocrystalline cellulose to 100 g of deionized aqueous solution, and ultrasonically disperse it into a homogeneous suspension with a mass fraction of 3 wt%, as phase A;

[0041] (2) Dissolve 4.5g of haloamine antibacterial agent precursor cyanuric chloride in 22.5ml of acetone, as phase B;

[0042] (3) At 0-5°C, use sodium carbonate solution to adjust the pH of Phase A to 9, slowly add Phase B to Phase A, keep stirring, and react for 2 hours. After the reaction, centrifuge the obtained solution at 10000rpm For 10 minutes, the obtained precipitate was washed three times with deionized water, and after the product was dispersed in water, it was dialyzed to neutrality with an 8000 molecular weight dialysis bag, and then concentrated to a concentration of 4 wt%, as phase C;

[0043] (4) Take 50 g of phase C, adjust the pH...

Embodiment 3

[0045] A nano-airgel composite material for antibacterial oil-water separation, the preparation method of which comprises the steps of:

[0046] (1) Add 6 g of nanocrystalline cellulose into 100 g of deionized aqueous solution, and ultrasonically disperse it into a homogeneous suspension with a mass fraction of 6 wt%, as phase A;

[0047] (2) Dissolve 6g of halamine antibacterial agent precursor cyanuric chloride in 10ml of ethanol as phase B;

[0048] (3) At 0-5°C, adjust the pH of phase A to 10 with sodium hydroxide solution, slowly add phase B into phase A dropwise, keep stirring, and react for 3.5 hours. After the reaction, the resulting solution was centrifuged at 10,000 rpm for 10 min, and the resulting precipitate was washed three times with deionized water. After the product was dispersed in water, it was dialyzed to neutrality with an 8,000 molecular weight dialysis bag, and then concentrated to a concentration of 6 wt%. as phase C;

[0049] (4) Take 50g of phase C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com