Self-reinforced multi-mode nano-structured thermal barrier coating with stable phase and preparation method thereof

A nanostructure and thermal barrier coating technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of coating failure, cracks in the coating, etc., and achieve good repeatability, process stability, Realize the effect of simple and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a phase-stabilized self-reinforced multi-mode nanostructure thermal barrier coating and a preparation method thereof, comprising the following steps:

[0032] (1) Yttria-stabilized zirconia (YSZ) spherical particle agglomerates are used as spraying raw materials; wherein, the diameter of the yttria-stabilized zirconia YSZ particle agglomerates is 30-70 μm, and the phase composition is a tetragonal phase structure. The internal grain size of YSZ spherical particle aggregates is 20-60nm.

[0033]The present invention uses nanostructured YSZ spherical particle agglomerates as spraying raw materials. One is based on the Hall-Petch empirical relationship, which clearly proposes that when the grain size is reduced to the nanometer scale (less than 100nm), the strength and hardness of the material will be greatly improved. . Based on this idea, the present invention applies nanostructured materials in the thermal spraying deposition process. By comprehe...

Embodiment 1

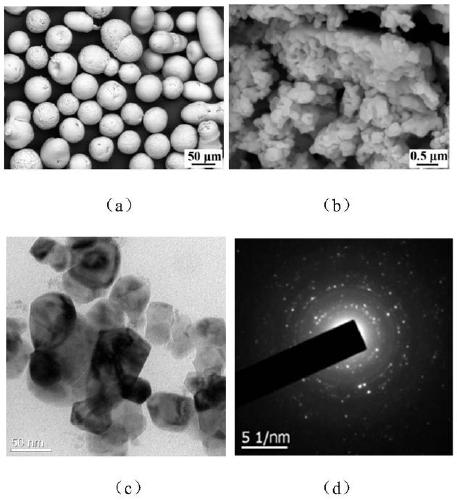

[0043] (1) The yttrium oxide partially stabilized zirconia YSZ particle aggregate structure in all embodiments of the present invention is as follows figure 1 Shown in (a), among the present invention, yttria partially stabilized zirconium dioxide YSZ particle agglomerates are used as spraying raw materials, figure 1 It can be seen that the diameter of the aggregate is 30-70 μm, and the mass fraction of yttrium oxide in the spraying raw material is 7% to 8%; the inside of the aggregate is analyzed, such as figure 1 In (b) and (c), it can be seen that the interior is composed of nanostructures with a grain size of 20-60nm, and further from figure 1 The SAED in (d) shows that its phase composition is a tetragonal phase structure.

[0044] (2) In the preparation process of thermal barrier coatings, firstly, superalloys and alloy powders are selected as the substrate and bonding layer raw materials of thermal barrier coatings (TBCs) system, and stacked layer by layer on the bondi...

Embodiment 2

[0049] Different from Example 1, the technological parameters of adopting the supersonic plasma spraying method in the step (3) are: arc current 550A, arc voltage: 150V, main gas flow (Ar): 155slpm, secondary gas flow (H 2 and N 2 ): 40slpm, spraying distance: 110mm, powder feeding rate 50g / min, Spray Watch 2i spray particle online monitoring system test results in particle flight speed of 700m / s, temperature 3700K. The contents of microcracks, rough cracks, melted and recrystallized zone pores, and unmelted nanometer zones in the coating were 9%, 12%, 1.5%, and 10%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com