Device and method for rapid finishing of high-hardness coating surface

A high-hardness, coating technology, used in grinding/polishing equipment, machine tools designed for grinding the rotating surface of workpieces, metal processing equipment, etc., can solve the problems of fast wear, low processing efficiency, and easy to produce vibration , to achieve high efficiency, good surface quality, and the effect of eliminating vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing and example.

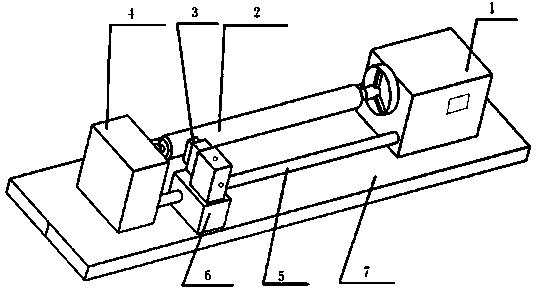

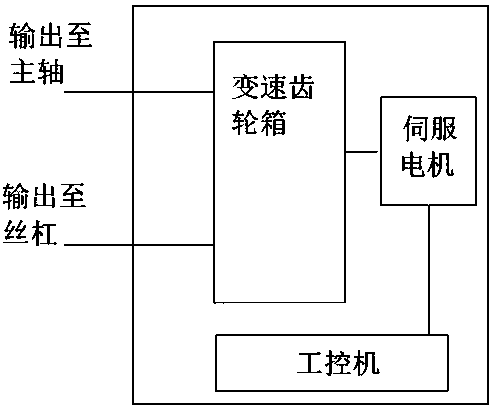

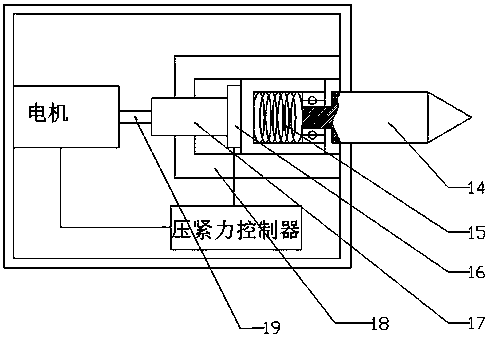

[0035] Such as figure 1 , 2 As shown, the present invention includes a high-speed rotary machine tool, a rotary bed headstock 1, a flexible diamond grinding head, a tailstock 4, a reciprocating machine 6, and a lead screw 5. The base plate 7 of the turntable is made of integrally polished steel plates. Its structure is a cuboid with mounting holes processed on it to fix the headstock 1 and tailstock 4 of the turntable. At the same time, the flatness of the overall plane allows the reciprocating machine 6 For the smoothness of movement, the flatness of the turntable base plate 7 is required to be no more than 0.1mm / m. The movable top 14 on the tailstock 4 and the spindle chuck on the headstock 1 of the turntable clamp and fix the high-hard coating workpiece 2 . Thus, the turntable forms a rigid platform, which can be placed on a stable platform with a suitable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com