PEC system for treating ammonia and generating electricity by photoelectrically activating persulfate through transitional bimetallic oxidation composite catalytic materials

A technology for oxidizing composite catalytic materials and activating persulfate, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, air quality improvement, etc., can solve secondary heavy metal pollution and cannot be easily separated And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

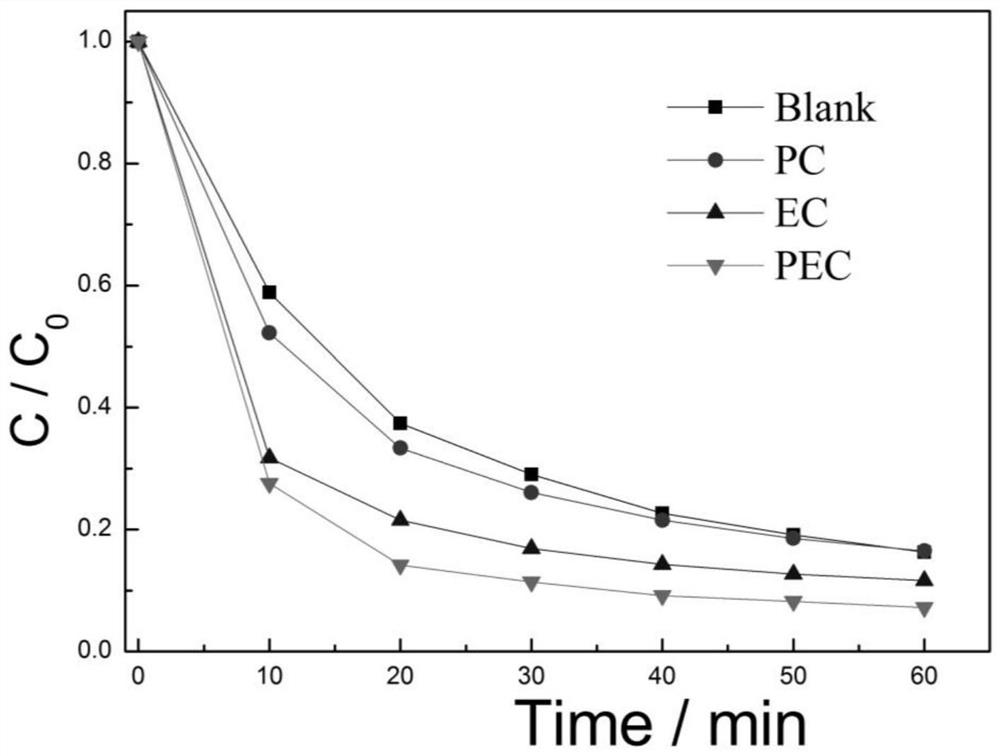

[0018] Example 1: PEC system photocatalytic removal of ammonia

[0019] The whole system is composed of ammonia gas generation part, photoelectric catalysis part, illumination part, circuit part and detection part. Specifically, it is as follows: a membrane module, a lamp, and a fan are placed in a stainless steel airtight reactor with a volume of 3.5 L, and after the lid is closed, 2 μL of NH is injected into the reactor. 3 ·H 2 O(100ppm NH 3 ), the fixed small fan in the system is turned on before the reaction, so that the injected ammonia water can be quickly volatilized in a short time and mixed evenly in the reactor. The rod corrodes in the electrolyte as the anode; the other chamber consists of CuO-Co 3 o 4 Catalyzed activated persulfate film is used as the cathode, and the two stages are connected to the external resistance through wires to form a closed circuit, and light is added after the reaction starts. During the treatment process, the ammonia gas concentrati...

Embodiment 2

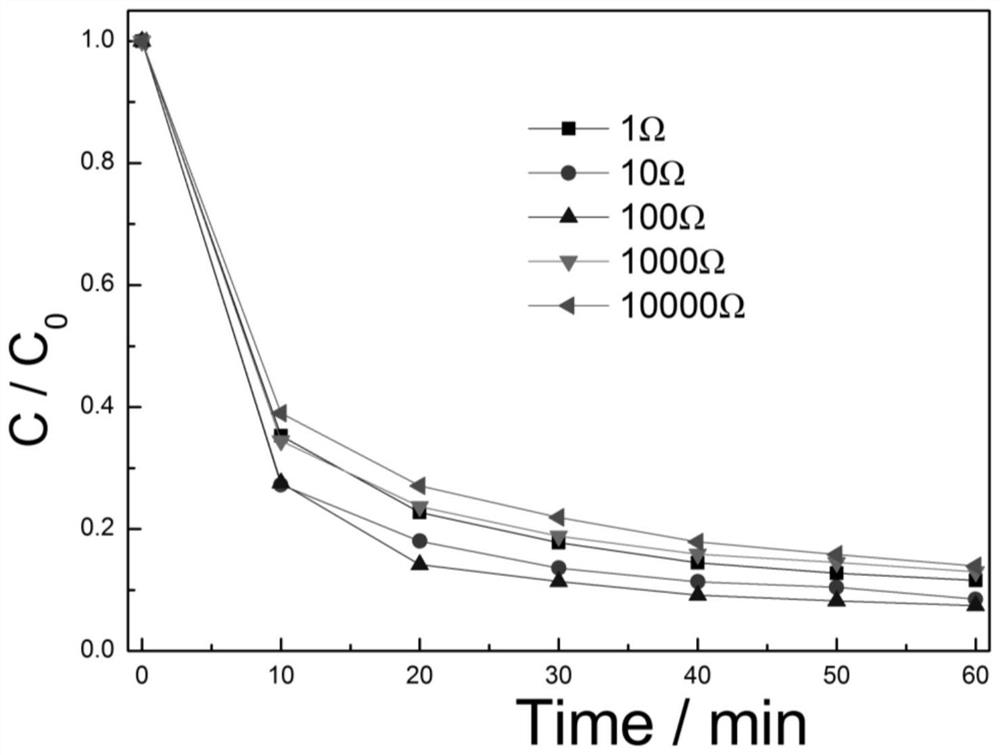

[0021] Example 2: Electrocatalytic system for treating toxic ammonia

[0022] The prepared CuO-Co 3 o 4The catalytically activated persulfate membrane is fixed on the membrane module, electrolyte and copper rod are added to the other pole of the membrane module, the membrane module is placed in a stainless steel reactor, the circuit is connected, the system is sealed, and 2.0uL ammonia water (100ppmNH 3 ), the fan in the reactor was turned on before the reaction, and after the reaction started, the ammonia concentration in the system was detected by a portable ammonia detector every 10 minutes, and the reaction time was 1 hour, and the removal efficiency of ammonia was calculated.

[0023] figure 2 Among them, under the conditions of different external resistances connected to the circuit, the electrocatalytic system treats ammonia. When the external resistance is 100Ω, the degradation efficiency of the system is the highest, which can reach 92.86%. Moreover, the electrici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com