Gel composite lithium metal electrode and preparation method and application thereof

A metal electrode and composite lithium technology, which is applied in the field of lithium-ion batteries, can solve the problems of gel layer and lithium negative electrode damage, and achieve the effect of simple and easy method, optimization of lithium deposition process, and improvement of lithium deposition cross section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

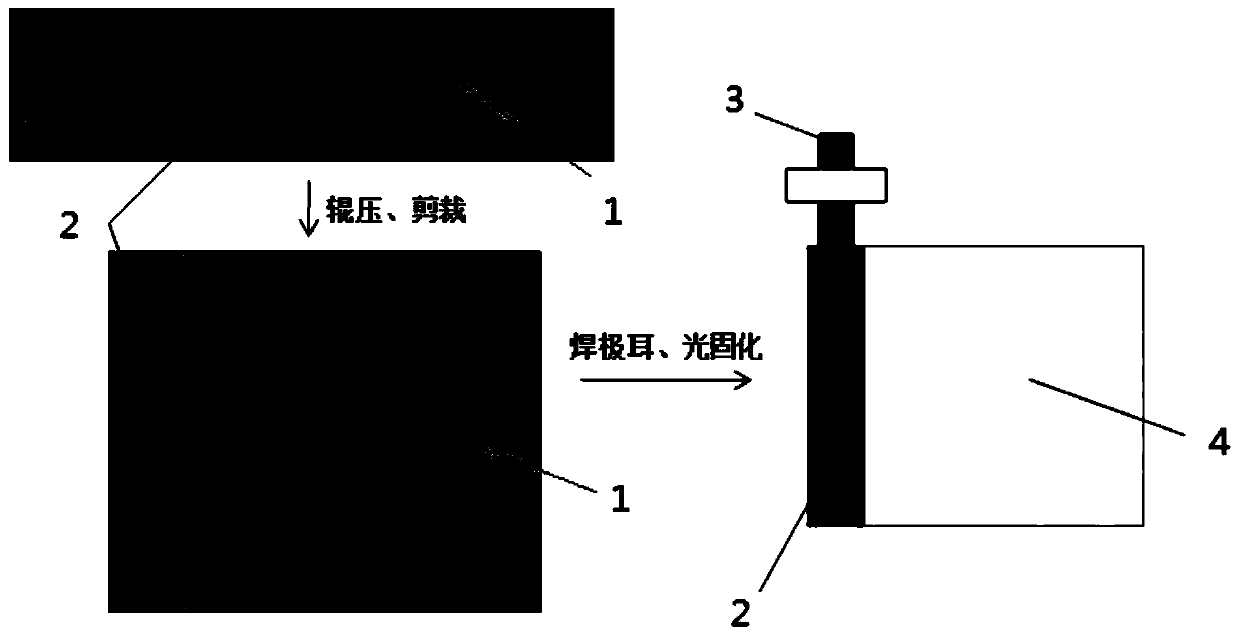

[0037] A preparation method of a gel composite lithium metal electrode, the method is as follows:

[0038] (1) Mix PVDF-HFP and ETPTA (containing 0.5wt% HMPP) in a mass ratio of 1:2, and add 1M LiClO that is 3 times the mass of the polymer mixture 4 TEGDME (triethylene glycol dimethyl ether) solution, and add the nanometer SiO of gross mass 5% 2 The powder is mixed and stirred evenly to make a photopolymerization precursor solution.

[0039] (2) Roll the lithium sheet (80μm) onto the copper foil (9μm), roll it to 70μm, cut the lithium sheet and copper foil together to 5*5cm, weld the negative tab on the copper foil, scrape the surface of the lithium sheet Apply the gel precursor solution with a scraping height of 120 μm.

[0040] (3) Set the wavelength of ultraviolet light to 365nm, and irradiate the gel precursor solution for photocuring for 30s, so as to prepare a single-sided gel composite lithium metal electrode.

Embodiment 2

[0042] A preparation method of a gel composite lithium metal electrode, the method is as follows:

[0043] (1) Mix PVDF-HFP and ETPTA (containing 1% HMPP) at a ratio of 1:3, add 0.6M LiTFSI&0.4M LiNO which is 1.5 times the mass of the polymer mixture 3 DOL / DME solution, and add 10% of the total mass of nano-Al 2 o 3 Powder, mix and stir evenly to make photopolymerization precursor solution.

[0044] (2) A layer of copper mesh (10 μm) is sandwiched between two lithium sheets (100 μm), and rolled to form a double-sided lithium sheet electrode. Using the spin coating method, the surface of the lithium wafer was spin-coated with a photopolymerization precursor solution with a thickness of 30 μm.

[0045] (3) Set the wavelength of ultraviolet light to 365nm, and irradiate the gel precursor liquid for photocuring for 20s. Flip the electrode over, apply the same gel precursor solution with a thickness of 30 μm on the other side, and light-cure for 20 seconds.

[0046] (4) Lead o...

Embodiment 3

[0054] Use the gel composite lithium metal electrode prepared in Example 1 as negative electrode, use 1M LiClO 4 The TEGDME solution is used as the electrolyte, and the carbon load is 1mg / cm 2 The Super-P electrode was used as an air electrode, and the assembled Li-O 2 Battery, set 0.1mA / cm 2 , constant volume 2mAh / cm 2 (ie 2000mAh / g) cycle. Such as Figure 7 As shown, the battery is stable for 20 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com