Milling method for controlling wall thickness uniformity of a thin-wall structural member

A thin-walled structural part, milling technology, applied in the direction of manufacturing tools, metal processing equipment, milling machine equipment, etc., can solve problems such as the inability to effectively control the wall thickness, and achieve the effect of reducing processing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

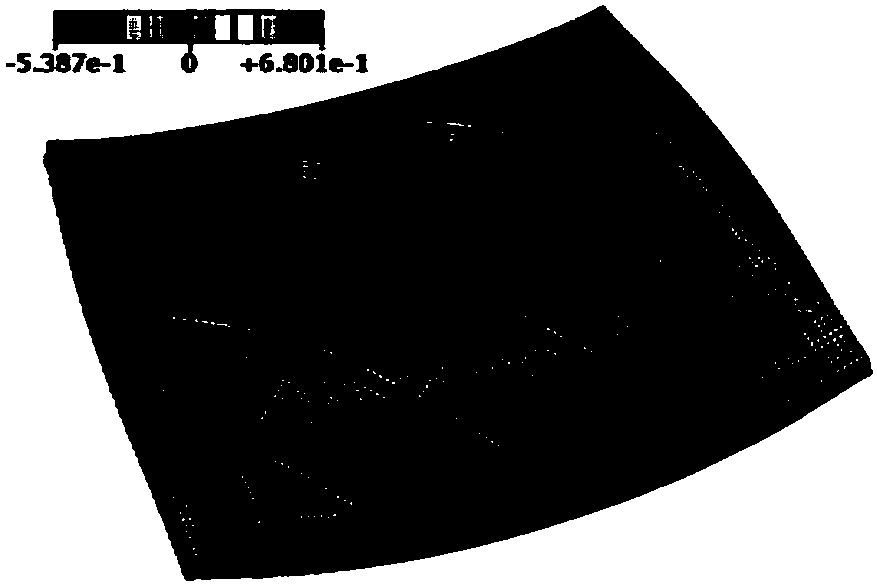

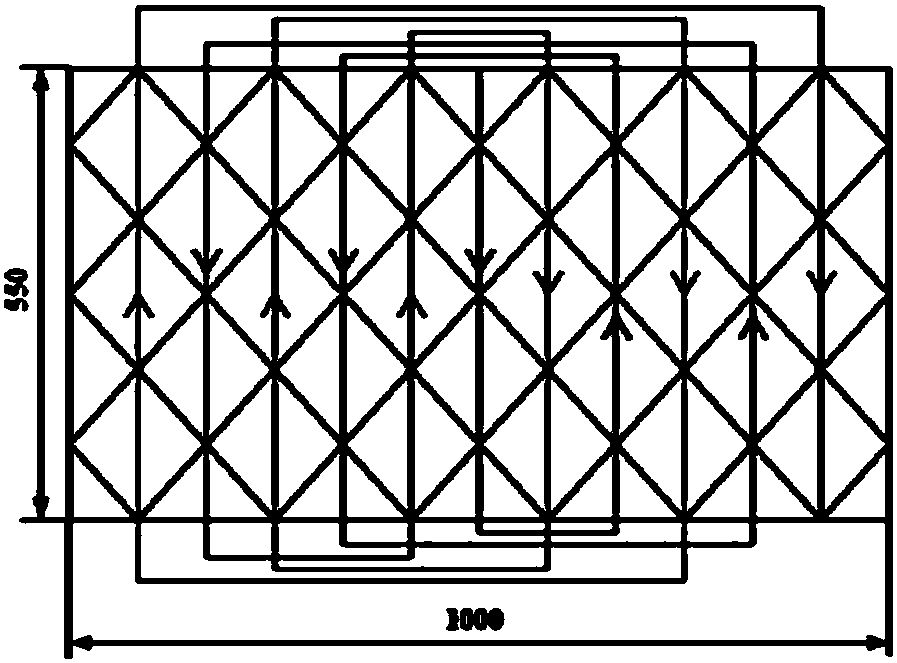

[0022] This embodiment is intended for figure 1 The wall thickness uniformity of the arc-shaped thin-walled wall plate structure shown in the milling process is controlled, that is, the spiral cutting method is used to cut into the workpiece, and the compound cutting method combining spiral cutting and cycloid cutting is adopted inside the cavity. The whole adopts a special way of cutting, processing layer by layer, and milling the grid-shaped cavity of thin-walled panels.

[0023] This embodiment is specifically realized through the following steps:

[0024] The first step is to analyze the dynamic mechanical behavior of the structural material through the Hopkinson compression bar experiment, and establish the J-C constitutive model of the 2219 aviation aluminum alloy as follows: Among them: A=376; B=230; C=0.0011; m=2.86; n=0.10; T m =816K.

[0025] The second step is to determine the optimal milling process parameters through the high-speed milling test: conduct a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com