Antibacterial anti-mildew self-cleaning nanometer antifouling coating material, preparation method and applications thereof

A technology for antibacterial, antifungal and antifouling coatings, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc. , limited antibacterial and antifungal effects, and achieve excellent self-cleaning performance, long antibacterial cycle, and improved antibacterial and antifungal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Another aspect of the embodiments of the present invention provides the preparation method of the aforementioned antibacterial, antifungal, self-cleaning nano-antifouling coating, which includes:

[0046] Disperse and mix organic fluorine resin and diluent evenly, then add organic-inorganic composite nano-antibacterial agent, nano-ceramic particles, nano-titanium dioxide, pigments and fillers, anti-sedimentation agent, dispersant and leveling agent, and mix evenly to form component A;

[0047] The A component and the B component curing agent are uniformly mixed to form an antibacterial, antifungal, self-cleaning nano antifouling coating.

[0048] In some specific embodiments, the preparation method may include:

[0049] Disperse and mix organic fluorine resin and diluent evenly, then add organic-inorganic composite nano-antibacterial agent, nano-ceramic particles, nano-titanium dioxide, pigments and fillers, anti-sedimentation agent, dispersant and leveling agent, stir ...

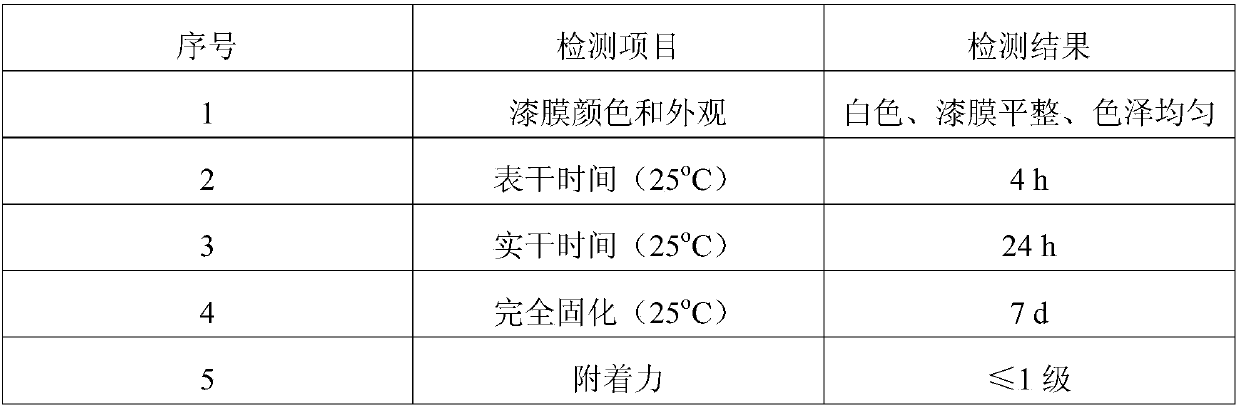

Embodiment 1

[0072] The present embodiment provides an antibacterial, mildew-proof, self-cleaning nano-antifouling coating (referred to as nano-antifouling coating), and its preparation method comprises:

[0073] (1) According to mass percentage (if not specified below, all refer to the mass percentage content of each component in A component), respectively take 40% of F-510 organic fluororesin, 10% of organic-inorganic composite nano antibacterial agent (nano Composition of silver and carboxybetaine type zwitterionic polymer with a mass ratio of 1:10), nano-ceramic particles 10% (a composition of nano-alumina and nano-zirconia with a mass ratio of 1:10), anatase type Nano titanium dioxide 5%, titanium dioxide 20%, organic bentonite 1%, dispersant 1%, leveling agent 1% and xylene 12%. Disperse and mix uniformly in a high-speed dispersing tank to prepare component A; take HDI as component B of isocyanate curing agent;

[0074] (2) Weigh 50% of component A and 50% of component B in the disp...

Embodiment 2

[0077] The present embodiment provides an antibacterial, mildew-proof, self-cleaning nano-antifouling coating (referred to as nano-antifouling coating), and its preparation method comprises:

[0078] (1) According to mass percentage (if not specified below, all refer to the mass percentage content of each component in A component), respectively take 50% of HY-F organic fluorosilicone resin and 1% of organic-inorganic composite nano-antibacterial agent ( Nano-silver and sulfobetaine-type zwitterionic polymer with a mass ratio of 0.1:1), nano-ceramic particles 5% (a composition of nano-alumina and nano-zirconia with a mass ratio of 0.1:1), anatase Type nano titanium dioxide 10%, talc powder 17%, anti-sedimentation agent 5%, dispersant 5%, silicone leveling agent 2% and n-butyl acetate 5%. Disperse and mix uniformly in a high-speed dispersing tank to prepare component A; take HDI three concrete as component B of isocyanate curing agent;

[0079] (2) Weigh 91% of A component and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com