Device for spraying pyrolyzing of copper nitrate solution and application method thereof

A technology of spray pyrolysis and copper nitrate, which is applied in the directions of combined devices, separation methods, chemical instruments and methods, can solve problems such as difficulty in comprehensive utilization of copper nitrate solution, achieve good economic benefits and resource and environmental benefits, realize precise control, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

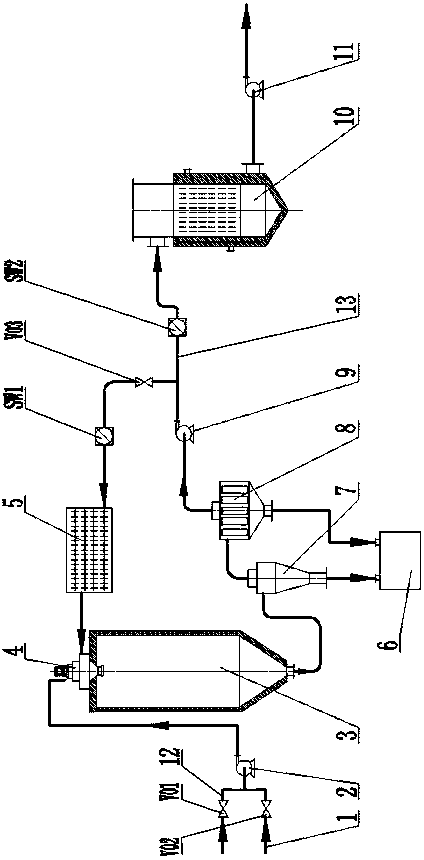

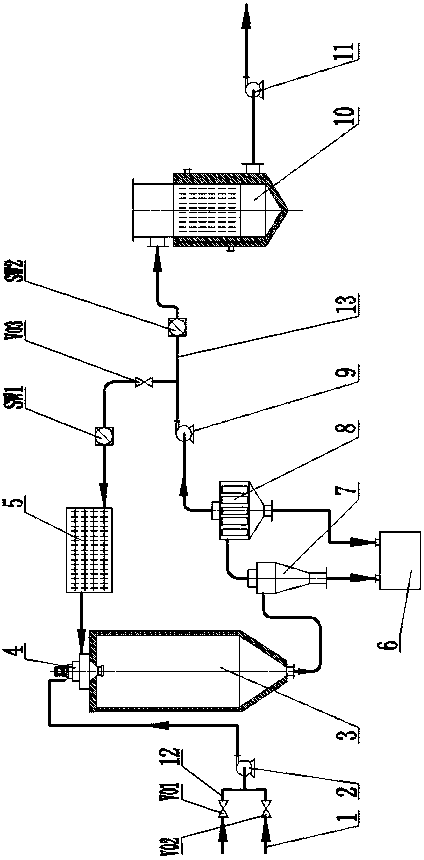

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] Such as figure 1 As shown, a device for spray pyrolysis of copper nitrate solution includes atomizer 4, pyrolysis furnace 3, heater 5 and dust collection system, and also includes feed system and high-pressure blower 9, and feed system includes material Pipeline 1 and feed pump 2, material pipeline 1 is connected to the inlet of feed pump 2, material valve V02 is provided on material pipeline 1, and the outlet of feed pump 2 passes through the pipeline and atomizer 4 The atomizer 4 is located above the pyrolysis furnace 3, the lower end of the pyrolysis furnace 3 is connected to the dust collection system through a pipe, the air inlet of the high-pressure fan 9 is connected to the dust collection system, and the air outlet of the high-pressure fan 9 is connected to the heater 5 through a pipe Link to each other, heater 5 links to each other with pyrolysis fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com