Composite conductive paste, preparation method and use thereof

A technology of composite conductive and conductive paste, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problems of limiting battery performance, poor dispersion, poor conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

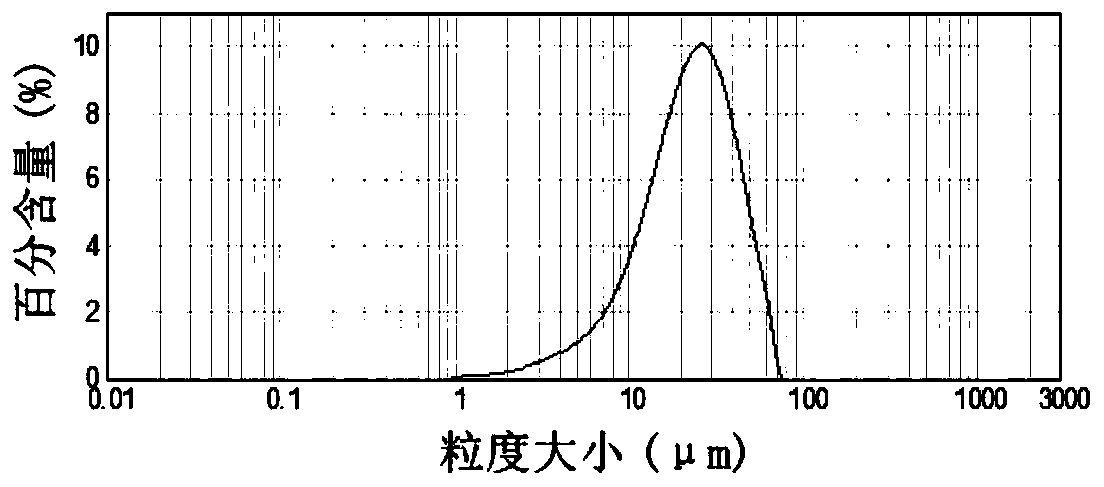

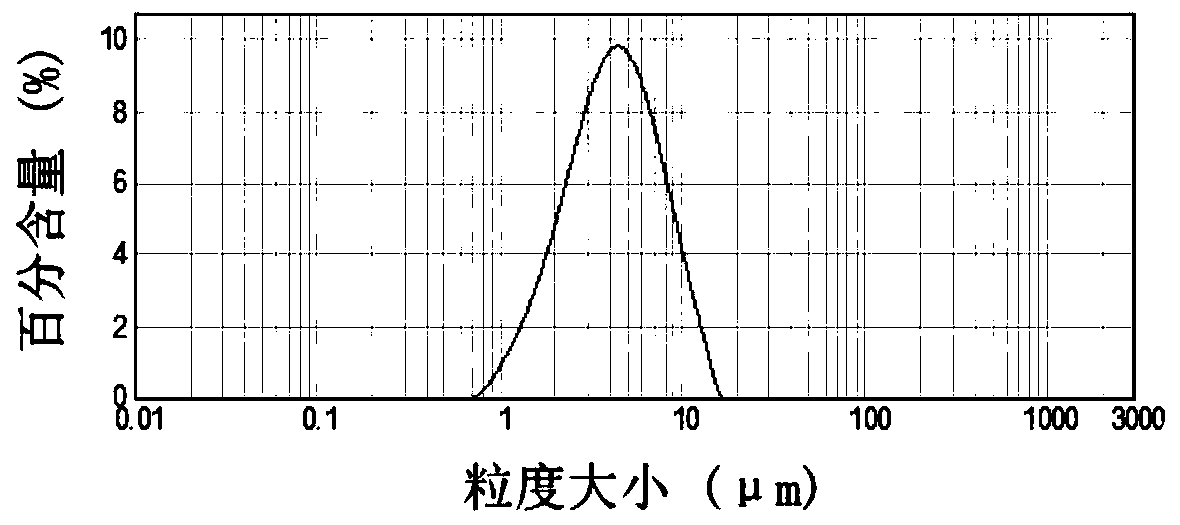

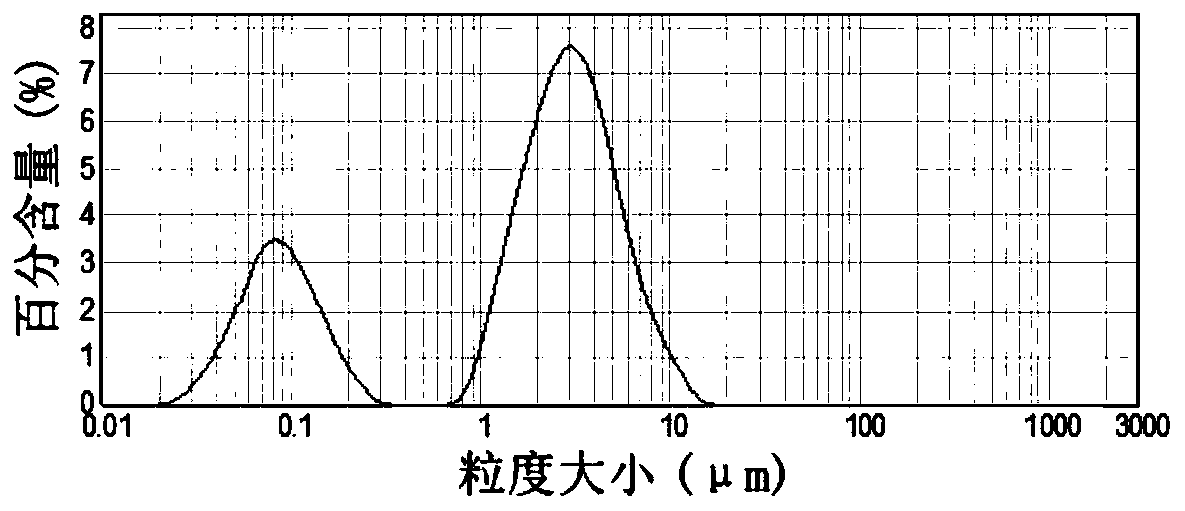

Image

Examples

Embodiment 1

[0092] This embodiment provides a composite conductive paste, which includes composite particles made of carbon nanotubes and graphene, a dispersant PVP, and a solvent NMP; wherein, the graphene is prepared by mechanical liquid phase exfoliation The obtained few-layer graphene, the number of layers of the few-layer graphene is 10-20 layers;

[0093] The carbon nanotubes are carbon nanotubes purified at high temperature, and the diameter of the carbon nanotubes is 10nm-20nm.

[0094] The detection results of ICP metal particle impurity content of graphene and high-temperature purified carbon nanotubes in Examples 1-4 of the present invention are shown in Table 1, wherein the unit of the data in Table 1 is ppm.

[0095] Table 1

[0096]

[0097] Preparation:

[0098] (1) Preparation of graphene conductive paste:

[0099] Each small batch produces 100Kg, wherein the ratio of dropping into natural graphite is: graphite: dispersant PVP=5:1, and the solid content of the graphe...

Embodiment 2

[0119] This embodiment provides a composite conductive paste, which includes composite particles made of carbon nanotubes and graphene coated on the surface of the carbon nanotubes, a dispersant PVP, and a solvent NMP; wherein, the The number of layers of the graphene is 5 layers, the diameter of the carbon nanotube is 10nm, and the length of the carbon nanotube is 5 μm to 8 μm;

[0120] The mass ratio of the total mass of the graphene and carbon nanotubes to the dispersant PVP is 5:1.25.

[0121] Preparation:

[0122] (1) Preparation of graphene conductive paste:

[0123] Each small batch produces 100Kg, wherein the ratio of graphite input is: graphite: dispersant PVP=5:1.25, and the solid content of the graphene conductive paste obtained is 4.8%.

[0124] (A): Accurately weigh the solvent NMP=95.2Kg, place it in a stirring tank, weigh the dispersant PVP=0.96Kg, add it into the stirring tank and stir for 20min until the dispersant is completely dissolved in the solvent;

...

Embodiment 3

[0136] The present embodiment provides a composite conductive paste, which includes composite particles made of carbon nanotubes and graphene, a dispersant PVP, and a solvent NMP; wherein, the number of layers of the graphene is 15 layers, The diameter of the carbon nanotubes is 15 nm, and the length of the carbon nanotubes is 5 μm to 8 μm; the mass ratio of the total mass of the graphene and carbon nanotubes to the dispersant PVP is 4:1.

[0137] (1) Preparation of graphene conductive paste:

[0138] Each small batch produces 100Kg, wherein the ratio of input graphite is: graphite: dispersant PVP=4:1, and the solid content of the graphene conductive paste obtained is 5%.

[0139] (A): Accurately weigh the solvent NMP=95Kg, place it in a stirring tank, weigh the dispersant PVP=1Kg, add it into the stirring tank and stir for 60 minutes until the dispersant is completely dissolved in the solvent;

[0140] (B): then take by weighing 4Kg of graphite, it is added in the dispersed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com