A kind of soi structure and its manufacturing process

A manufacturing process and technology of silicon wafers, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve problems such as poor heat dissipation of SOI, improve heat dissipation performance, improve heat dissipation capacity, and inhibit self-heating effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

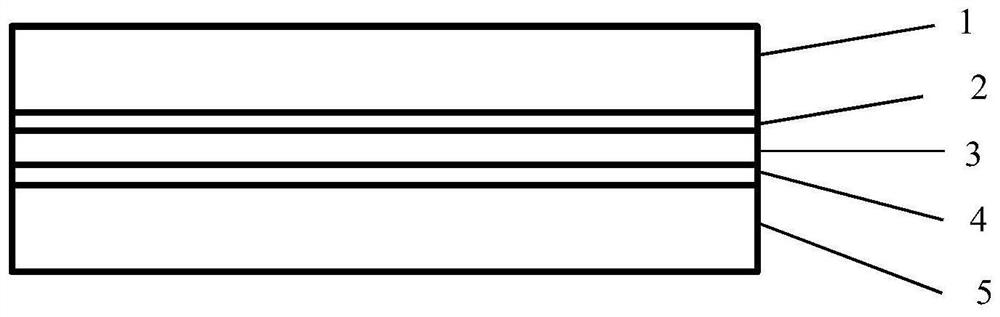

[0036] Manufacturing process of the present invention comprises the following steps:

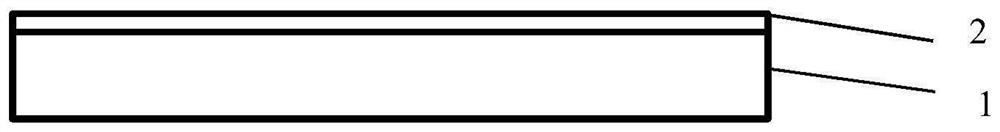

[0037] 1) if figure 2 As shown, a layer of about 10nm silicon dioxide film is sputtered on the surface of the first silicon wafer layer 1 by radio frequency sputtering as the silicon dioxide layer 2;

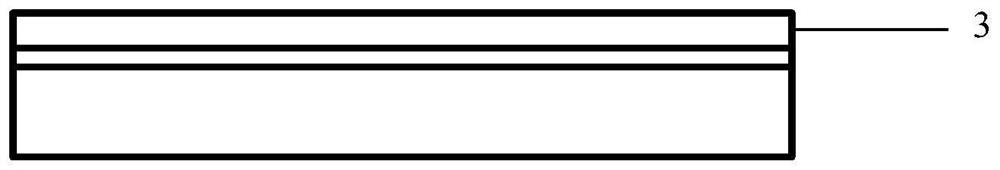

[0038] 2) if image 3 As shown, a layer of boron nitride film with a thickness of about 700 nm is sputtered on the surface of the silicon dioxide layer 2 in step 1 as the boron nitride layer 3;

[0039] 3) if Figure 4 As shown, a layer of silicon with a thickness of about 1 μm is sputtered on the surface of the boron nitride layer 3 in step 2 as the silicon layer 4;

[0040] 4) if Figure 5 As shown, the surface of the silicon layer 4 obtained in step 3 is polished by chemical mechanical polishing, and then the polished silicon layer 4 is thermally bonded to the second silicon wafer layer 5 to obtain an inverted SOI structure;

[0041] 5) if Figure 6 As shown, the inverted SOI structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com