Preparation method of recyclable paper-based friction material

A technology of paper-based friction material and preparation steps, which is applied in the field of friction materials, can solve the problems of friction materials such as heat decay, friction coefficient drop, and short service life, so as to improve mechanical fatigue resistance, surface friction performance, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

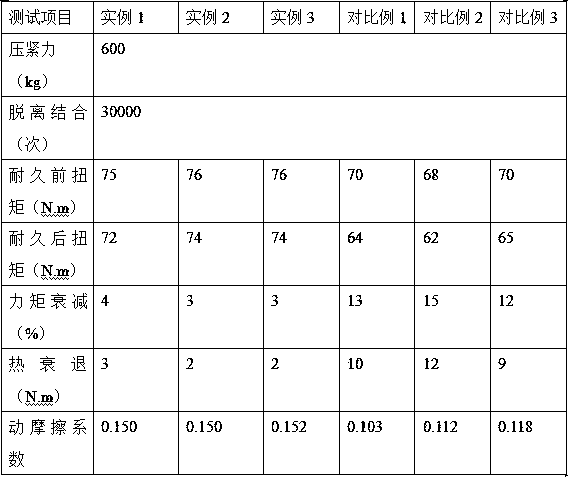

Examples

preparation example Construction

[0029] Preparation of the surface modified paper layer: the kraft larch wood pulp with a mass fraction of 35% and the Ye wood pulp with a mass fraction of 40% are mixed to obtain a mixed wood pulp, and the mixed wood pulp is poured into a PFI refiner, Refining for 5 minutes, controlling the degree of beating of the mixed wood pulp to be 30°SR to obtain paper pulp, putting the obtained pulp into papermaking equipment for drying and calendering, and controlling the pressure to be 0.6MPa to obtain a base paper layer;

[0030] Add 80g of phenol, 85mL of formaldehyde solution with a mass fraction of 37% and 1g of sodium hydroxide into the reaction kettle, heat up to 70°C, keep the temperature for 1h, and when cooled to 35°C, put the base paper layer into the reaction kettle for 30min and take out The impregnated base paper layer is put into a low-temperature plasma treatment equipment, and under an argon atmosphere, the control power is 30W, the air pressure is 40Pa, and the treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com