A kind of copper red matt kiln changing glaze and preparation method thereof

A technology of bottom glaze and surface glaze, which is applied in the field of ceramic glaze, can solve the problems of high difficulty in making kiln-changing glaze and poor kiln-changing effect, and achieve the effect of beautiful and generous products, delicate glazed surface and smooth glazed surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

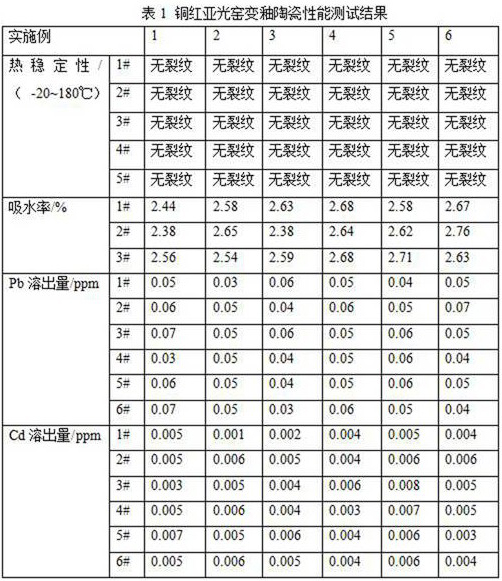

Examples

Embodiment 1

[0039] A copper-red matt kiln-changing glaze, the copper-red matt kiln-changing glaze is composed of a bottom glaze and a top glaze, the bottom glaze is applied on a ceramic body, and the top glaze is applied on the bottom glaze:

[0040] The bottom glaze includes the following components by weight: 25 parts of refined potassium feldspar, 1.8 parts of animal ashes, 12 parts of refined quartz, 9 parts of lime, 4 parts of talc, 4 parts of refined cordierite, 8 parts of silicon carbonate, copper oxide 1.5 parts, 4 parts of tin oxide, 4 parts of zinc oxide, 5 parts of aluminum oxide, 12 parts of barium carbonate, 15 parts of boron;

[0041] The surface glaze includes the following components by weight: 15 parts of refined potassium feldspar, 8 parts of refined quartz, 4 parts of talc, 8 parts of zirconium phosphate, 4 parts of titanium oxide, 4 parts of tin oxide, 35 parts of frit, and refined dolomite 6 parts of stone, 6 parts of zinc oxide, 1.5 parts of copper oxide;

[0042] T...

Embodiment 2

[0053] A copper-red matt kiln-changing glaze, the copper-red matt kiln-changing glaze is composed of a bottom glaze and a top glaze, the bottom glaze is applied on a ceramic body, and the top glaze is applied on the bottom glaze:

[0054] The bottom glaze includes the following components by weight: 35 parts of refined potassium feldspar, 2.2 parts of animal ashes, 18 parts of refined quartz, 11 parts of lime, 6 parts of talc, 6 parts of refined cordierite, 12 parts of silicon carbonate, copper oxide 2.5 parts, 6 parts of tin oxide, 6 parts of zinc oxide, 8 parts of aluminum oxide, 18 parts of barium carbonate, 25 parts of boron;

[0055] The surface glaze includes the following components by weight: 25 parts of refined potassium feldspar, 12 parts of refined quartz, 6 parts of talc, 12 parts of zirconium phosphate, 8 parts of titanium oxide, 6 parts of tin oxide, 45 parts of frit, and refined dolomite 10 parts of stone, 10 parts of zinc oxide, 2.5 parts of copper oxide;

[0...

Embodiment 3

[0067] A copper-red matt kiln-changing glaze, the copper-red matt kiln-changing glaze is composed of a bottom glaze and a top glaze, the bottom glaze is applied on a ceramic body, and the top glaze is applied on the bottom glaze:

[0068] The bottom glaze includes the following components by weight: 28 parts of refined potassium feldspar, 1.9 parts of animal ashes, 14 parts of refined quartz, 9 parts of lime, 4.5 parts of talc, 4.5 parts of refined cordierite, 9 parts of silicon carbonate, copper oxide 1.8 parts, 4.5 parts of tin oxide, 4.5 parts of zinc oxide, 6 parts of aluminum oxide, 14 parts of barium carbonate, 18 parts of boron;

[0069] The surface glaze includes the following components by weight: 18 parts of refined potassium feldspar, 9 parts of refined quartz, 4.5 parts of talc, 9 parts of zirconium phosphate, 5 parts of titanium oxide, 4.5 parts of tin oxide, 38 parts of frit, and refined dolomite 7 parts of stone, 7 parts of zinc oxide, 1.8 parts of copper oxide;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com