A kind of indoor floor and its preparation process

A floor and process technology, applied in the field of indoor floor and its preparation process, can solve problems such as surface hardness, poor dimensional stability and anti-warping performance, affect the ecological balance of the natural environment, consume natural resources, etc., to save heat Pressing process, excellent dimensional stability, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

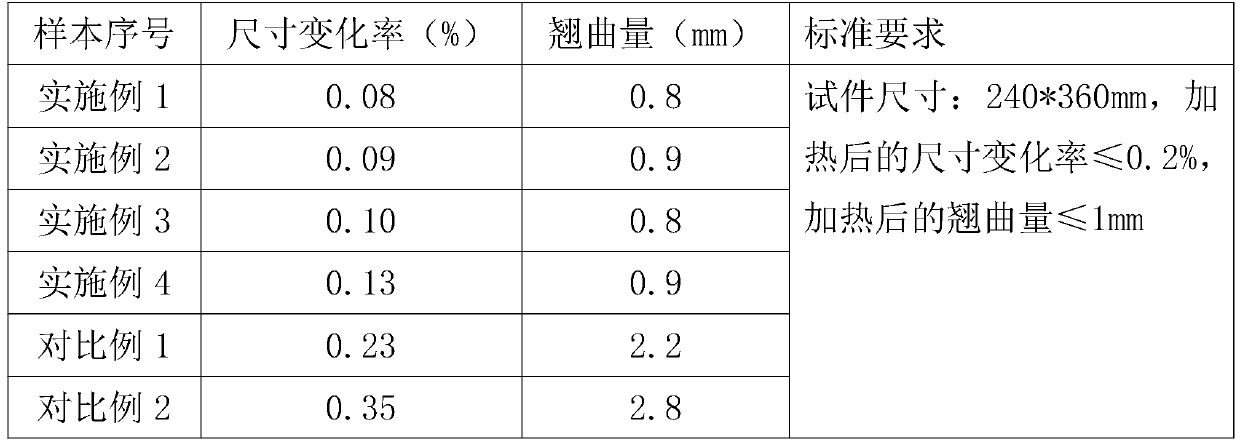

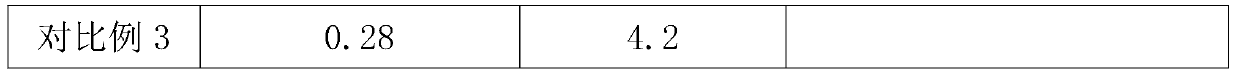

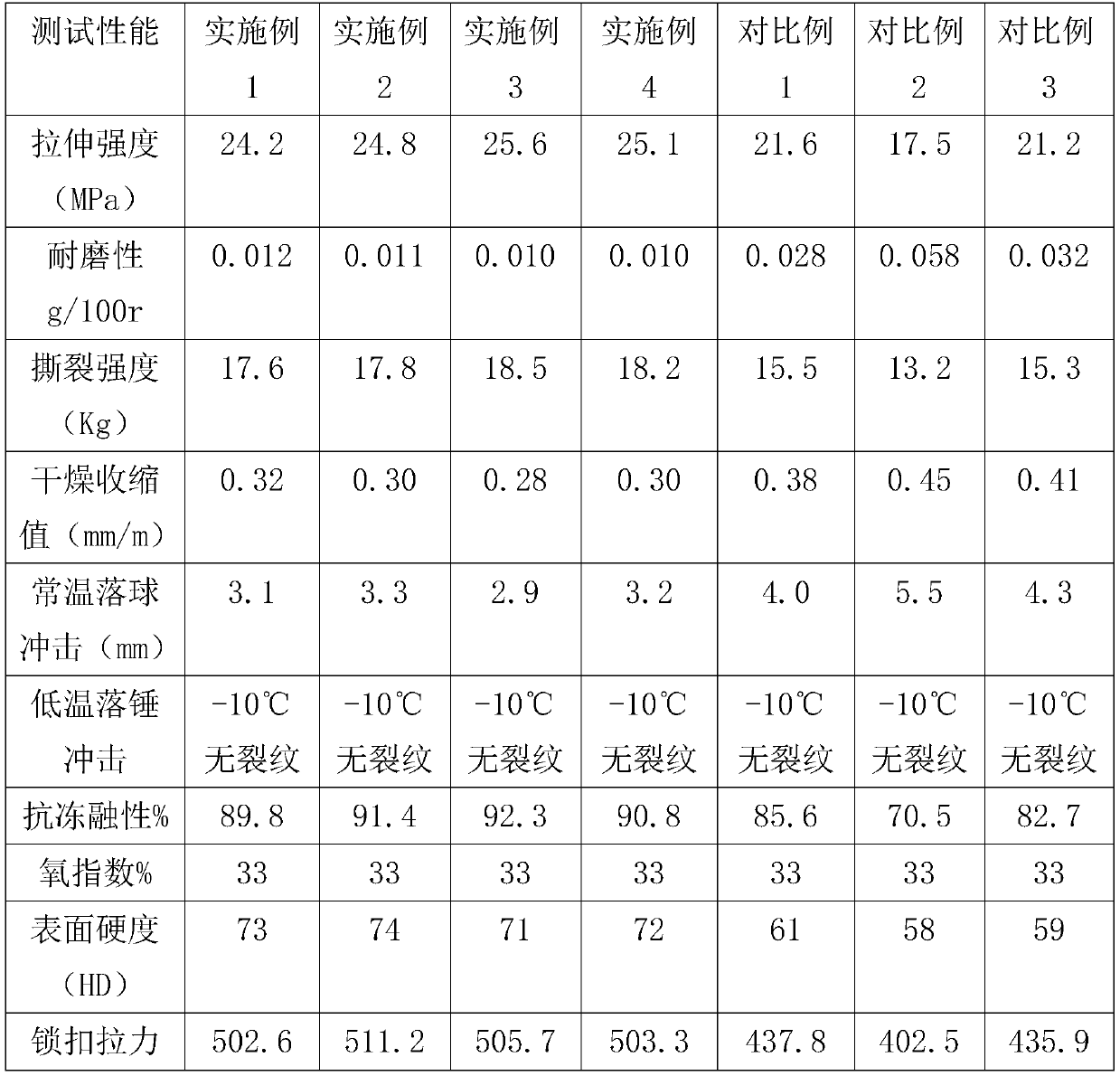

Examples

Embodiment 1

[0029] A kind of indoor floor, is made up of SPC surface layer and bamboo-plastic foam core layer, and the thickness ratio of SPC surface layer and bamboo-plastic foam core layer is 1:2;

[0030] The SPC surface layer is made of the following raw materials in mass fractions: 100 parts of PVC resin powder, 10 parts of DOTP, 1 part of SF-10 flexible agent, 3 parts of silane coupling agent KH550, 40 parts of heavy calcium carbonate powder, and calcium-zinc composite stabilizer 3 parts, 1 part of phosphite antioxidant, 6 parts of ACR-401, 1 part of calcium stearate, 4 parts of stearic acid;

[0031] The bamboo-plastic foam core layer is made of the following raw materials in mass fractions: 100 parts of polyethylene particles, 20 parts of modified bamboo powder, 4 parts of bamboo charcoal, 4 parts of nano-active calcium carbonate, 1.5 parts of AC1601, and 0.8 parts of borate ester coupling agent , 4 parts of chlorinated polyethylene, 6 parts of acrylic acid, 10 parts of zinc stear...

Embodiment 2

[0042] A kind of indoor floor, is made up of SPC surface layer and bamboo-plastic foam core layer, and the thickness ratio of SPC surface layer and bamboo-plastic foam core layer is 1:3;

[0043] The SPC surface layer is made of the following raw materials in mass fractions: 120 parts of PVC resin powder, 20 parts of DOTP, 4 parts of SF-10 flexible agent, 5 parts of silane coupling agent KH550, 100 parts of heavy calcium carbonate powder, and calcium-zinc composite stabilizer 5 parts, 3 parts of phosphite antioxidant, 10 parts of ACR-401, 3 parts of calcium stearate, 6 parts of stearic acid;

[0044] The bamboo-plastic foam core layer is made from the following raw materials in mass fractions: 120 parts of ethylene-propylene copolymer particles, 60 parts of modified bamboo powder, 6 parts of bamboo charcoal, 8 parts of nano-active calcium carbonate, 3 parts of AC1601, boric acid ester coupling 1.2 parts of agent, 8 parts of chlorinated polyethylene, 12 parts of acrylic acid, 1...

Embodiment 3

[0055] A kind of indoor floor, is made up of SPC surface layer and bamboo-plastic foam core layer, and the thickness ratio of SPC surface layer and bamboo-plastic foam core layer is 1:2;

[0056] The SPC surface layer is made of the following raw materials in mass fractions: 110 parts of PVC resin powder, 15 parts of DOTP, 2 parts of SF-10 flexible agent, 4 parts of silane coupling agent KH550, 50 parts of heavy calcium carbonate powder, and calcium-zinc composite stabilizer 4 parts, 2 parts of phosphite antioxidant, 8 parts of ACR-401, 2 parts of calcium stearate, 5 parts of stearic acid;

[0057] The bamboo-plastic foam core layer is made of the following raw materials in mass fractions: 110 parts of polyethylene and polypropylene plastic particles with a ratio of 1:1, 30 parts of modified bamboo powder, 5 parts of bamboo charcoal, 6 parts of nano-active calcium carbonate, AC1601 2 parts, 1 part of borate ester coupling agent, 6 parts of chlorinated polyethylene, 8 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com