Hydrofoil surface fluid resistance testing device capable of achieving flow jetting

A testing device and fluid resistance technology, which is applied in the direction of fluid dynamics test, measuring device, machine/structural component testing, etc. It can solve problems such as difficult installation and disassembly, difficult jet surface resistance measurement, cumbersome operation, etc., to achieve convenient loading and unloading , low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

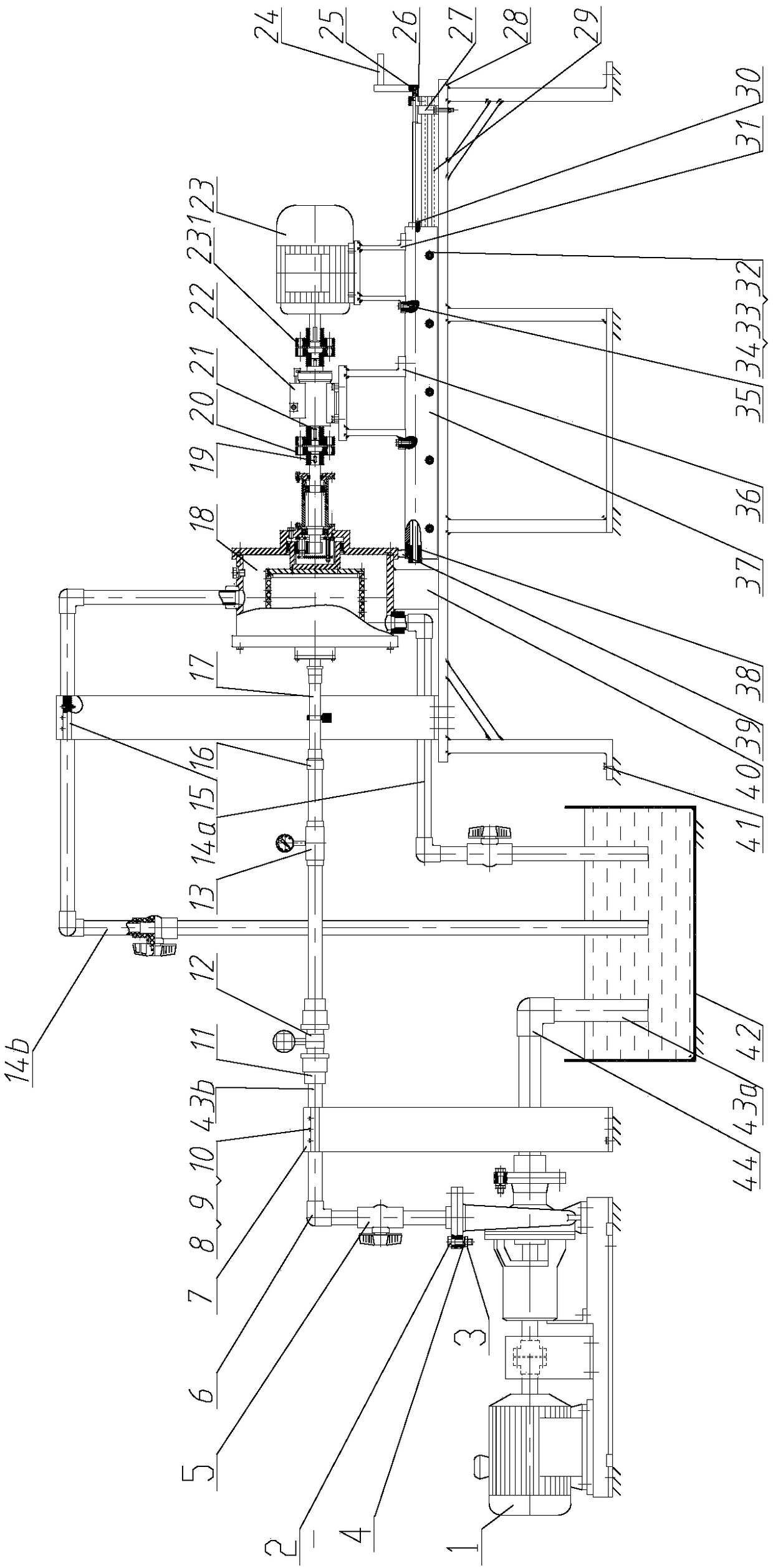

[0029] Embodiment 1 A kind of hydrofoil surface fluid resistance testing device that can realize jet flow according to the present invention includes:

[0030] The frame body includes a test platform support 28 with a working platform and a position adjustment device installed on the working platform, wherein the fixing part of the position adjusting device is paved on the working platform, and the fixing part can be installed along the axial direction of the fixing part. Sliding moving parts, used to adjust the power transmission system and the installation position of the hydrofoil test sample test system;

[0031] The power transmission system includes a drive device, a torque signal acquisition unit and a force transmission unit. The drive device and the torque signal acquisition unit are coaxially installed on the moving part of the position adjustment device, and the power output end of the drive device is connected to the power of the torque signal acquisition unit. The...

Embodiment 2

[0046] Embodiment 2 A hydrofoil surface fluid resistance testing device capable of jet flow according to the present invention includes a frame body, a power transmission device, a hydrofoil test sample testing device and a water supply device, and the power transmission device is installed on the on the frame, and the power output end of the power transmission device is connected to the hydrofoil test sample testing device, and the water supply device is used to provide the water flow velocity for the device test, and is arranged on the hydrofoil The side of the test sample testing device away from the power transmission end is connected with the frame body.

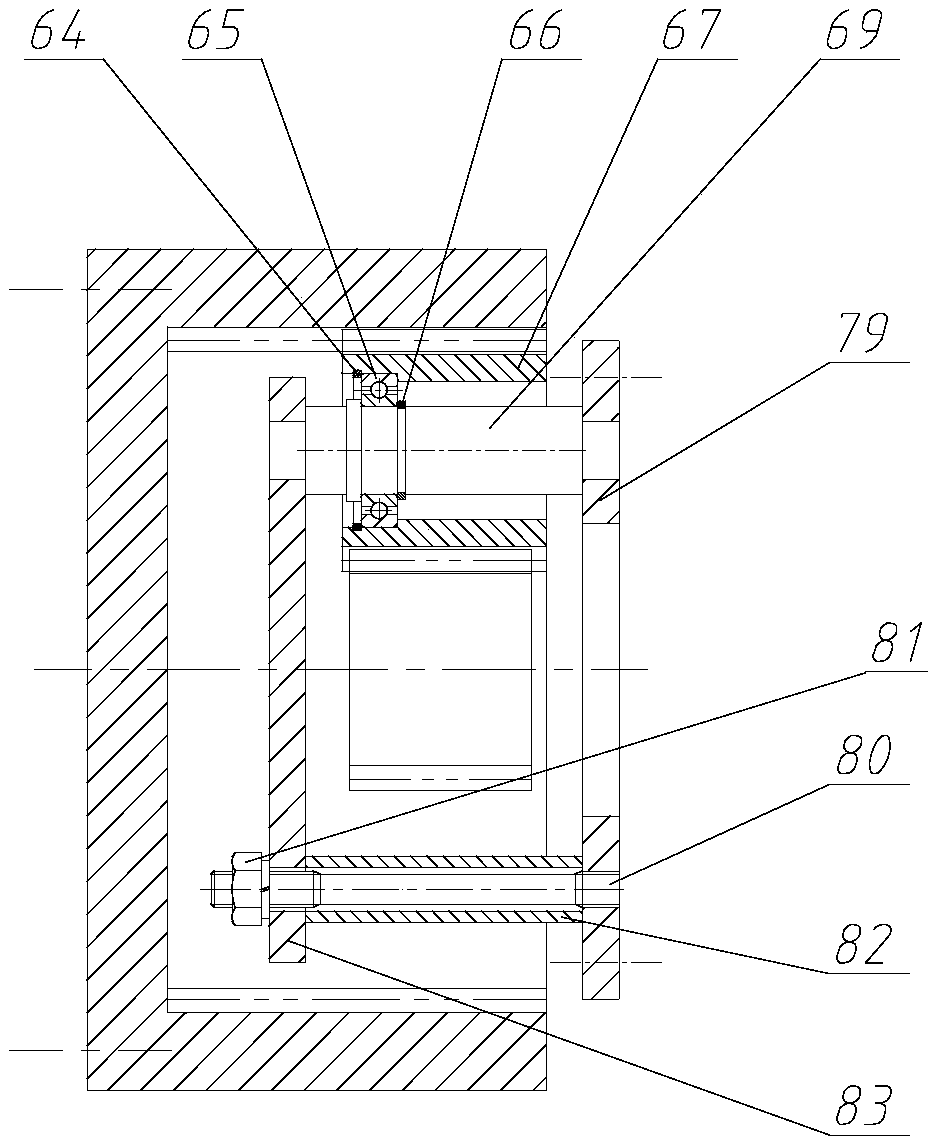

[0047] combine figure 1 , figure 2 , in the input gear shaft of the power transmission device: the motor support 31 is installed on the rail platform 37 of the frame body, the motor 23 is installed on the motor support 31, the The output shaft of the motor 23 is affixed to the power input end of the torque signal cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com