Large-particle perovskite single crystal/polymer composite thick film, photoelectric detector and preparation method

A photodetector and perovskite technology, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electric solid-state devices, etc., can solve problems such as the difficulty in preparing perovskite single crystal thick films, achieve excellent charge transport performance, and prepare The effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

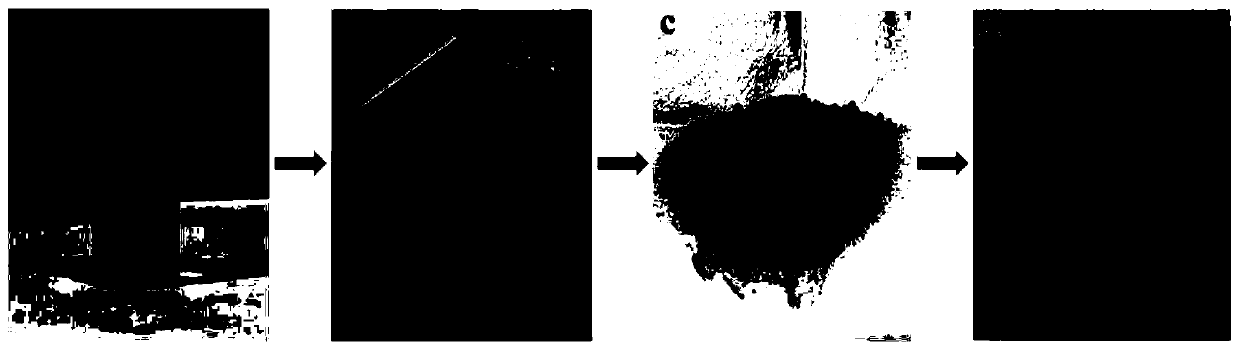

[0037] Such as figure 1 As shown, the preparation method of the large-grain perovskite single crystal / polymer composite thick-film photodetector provided in this embodiment includes the following steps:

[0038] 1) Preparation of methylamine lead iodide salt (CH 3 NH 3 PB 3 ) perovskite single crystal, the methylamine lead iodide salt was fully dissolved at 60°C to obtain a saturated solution, and after filtration, it was continuously heated at 120°C for 6 hours to obtain a methylamine lead iodide salt perovskite single crystal, in which the large particle perovskite The ore single crystal diameter is 1.5cm;

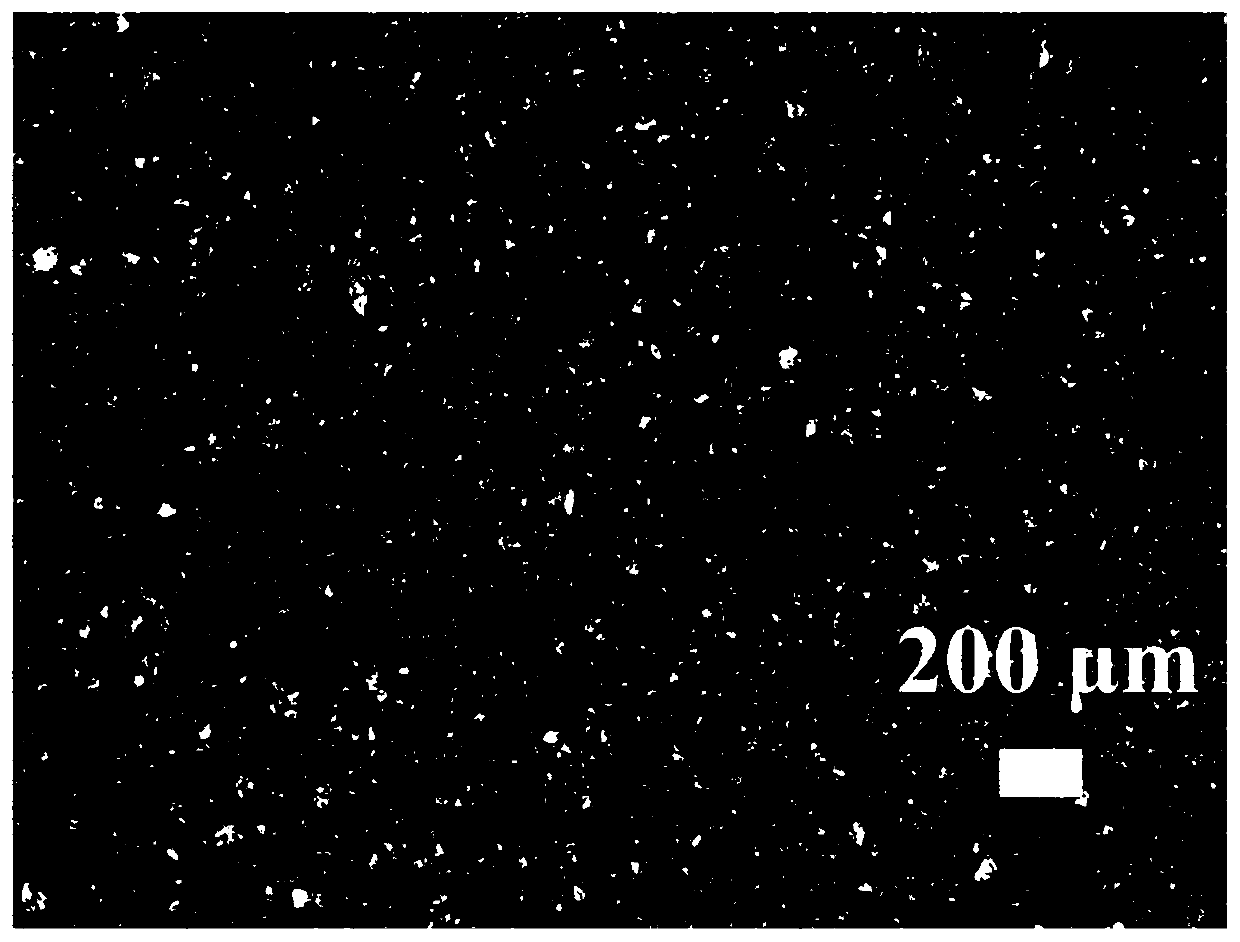

[0039] 2) After drying the methylamine lead iodide perovskite single crystal in step 1), perform mechanical grinding and sieving to obtain methylamine lead iodide perovskite single crystal particles, and dry in a vacuum oven at 60° C. for 24 hours. The obtained single crystal particle diameter is 500nm;

[0040] 3) A mixed solution of the methylamine lead iodide per...

Embodiment 2

[0044] Such as figure 1 As shown, the preparation method of the large-grain perovskite single crystal / polymer composite thick-film photodetector provided in this embodiment includes the following steps:

[0045] 1) Preparation of methylamine lead bromide (CH 3 NH 3 PbBr 3 ) perovskite single crystal, fully dissolve methylamine lead bromide salt at 40°C to obtain a saturated solution, filter and continue heating at 100°C for 4 hours to obtain methylamine lead bromide salt perovskite single crystal, in which large particle perovskite The ore single crystal diameter is 1cm;

[0046] 2) After drying the methylamine lead bromide perovskite single crystal in step 1), perform mechanical grinding and sieving to obtain methylamine lead bromide perovskite single crystal particles, and dry it in a vacuum oven at 80° C. for 16 hours. The obtained single crystal particle diameter is 800nm;

[0047] 3) The mixed solution of the methylamine lead bromide salt perovskite single crystal pa...

Embodiment 3

[0051] Such as figure 1 As shown, the preparation method of the large-grain perovskite single crystal / polymer composite thick-film photodetector provided in this embodiment includes the following steps:

[0052] 1) Preparation of formamidine lead iodide salt (CH(NH 2 ) 2 PB 3 ) perovskite single crystal, fully dissolve formamidine lead iodide salt at 70°C to obtain a saturated solution, filter and continue heating at 130°C for 8 hours to obtain formamidine lead iodide salt perovskite single crystal, in which large particle perovskite The ore single crystal diameter is 0.5cm;

[0053] 2) After drying the formamidine lead iodide perovskite single crystal in step 1), perform mechanical grinding and sieving to obtain formamidine lead iodide perovskite single crystal particles, and dry it in a vacuum oven at 100° C. for 12 hours. The obtained single crystal particle diameter is 900nm;

[0054] 3) A mixed solution of formamidine lead iodide salt perovskite single crystal partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com