Method for imparting crimp structure to polymer micro-nano fiber

A micro-nano fiber and micro-nano technology, applied in the direction of fiber type, fiber treatment, fabric elongation, etc., can solve the problems of disappearance of mechanical nonlinearity, instability of mechanical nonlinearity, uncertainty of crimp structure, etc., and increase the degree of orientation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

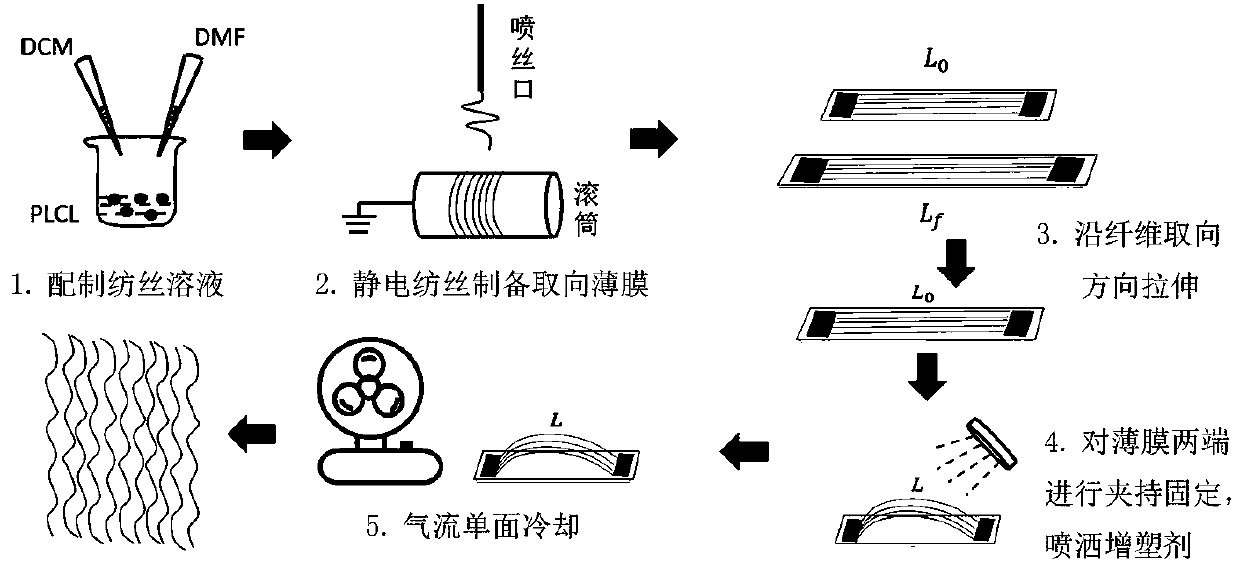

[0045] A method for giving L-polylactic acid-polycaprolactone copolymer micro-nano fiber crimped structure, comprising the following steps:

[0046] (1) Dichloromethane (DCM) and dimethylformamide (DMF) are configured into 10ml solution at a ratio of 7:3, and 1g of L-polylactic acid-polycaprolactone copolymerized with an intrinsic viscosity of 3.6dl / g is added to it. Stir until the left-handed polylactic acid-polycaprolactone copolymer is completely dissolved to obtain a spinning solution of the left-handed polylactic acid-polycaprolactone copolymer, and then use the spinning solution of the left-handed polylactic acid-polycaprolactone copolymer The oriented micro-nanofiber film prepared by electrospinning into a planar structure (receive the micro-nanofiber film on the drum, cut it along the axial direction after receiving, and obtain the micro-nanofiber film; the oriented micro-nanofiber film refers to the micro-nanofiber film. The fibers in the film are preferentially arran...

Embodiment 2

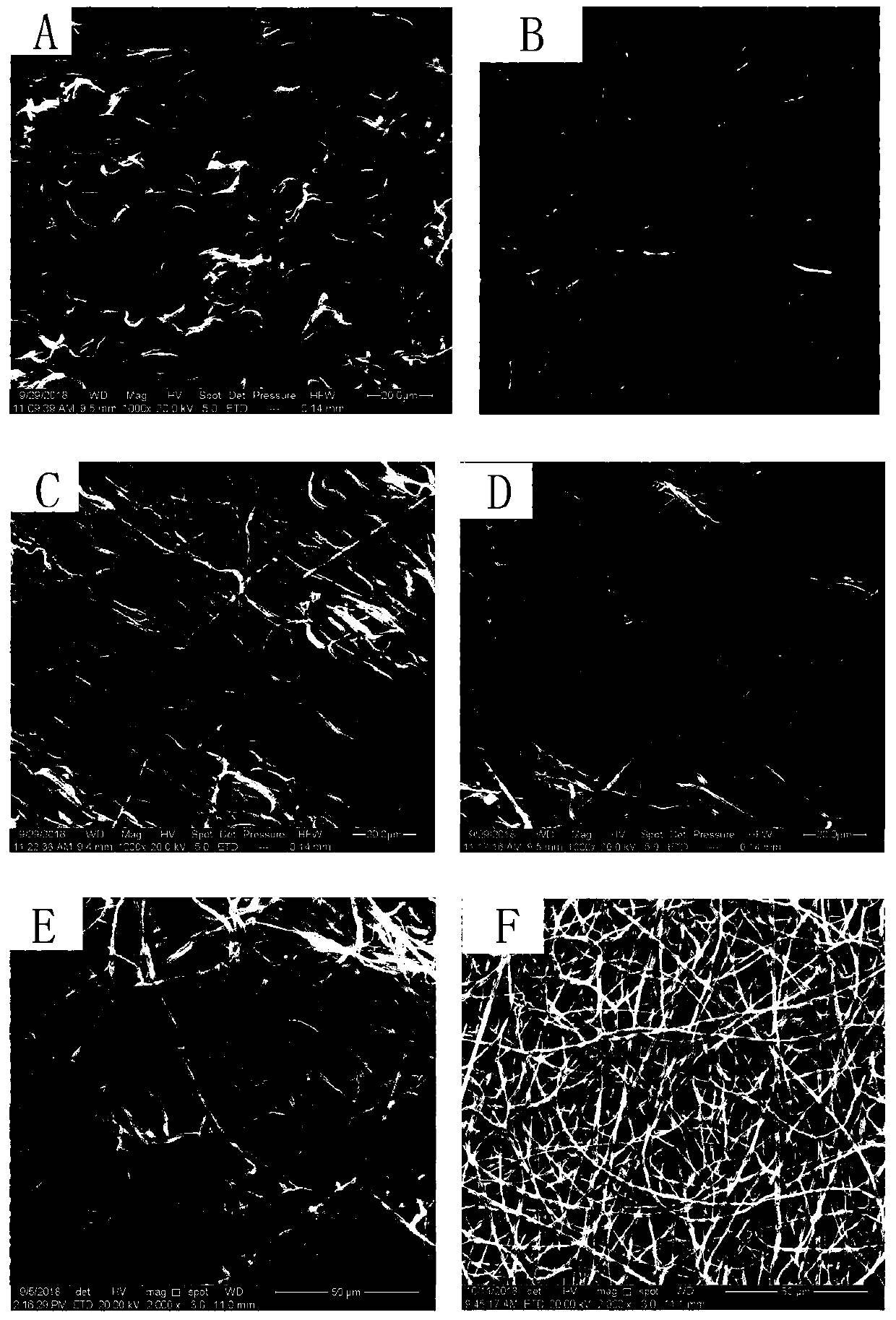

[0054] The content of embodiment 2 is basically the same as embodiment 1, and its difference is:

[0055] In step (2): stretching the micro-nanofiber film prepared in step (1) continuously for five times along the fiber orientation direction, the stretching ratio of each stretching is 120%.

[0056] Using the method described in this example, a L-polylactic acid-polycaprolactone copolymer micro-nanofiber film with a stable fiber crimp structure can be prepared, and the curl degree of the fiber crimp structure is 0.389. A uniaxial tensile test was carried out on the L-polylactic acid-polycaprolactone copolymer micro-nanofiber film with a fiber crimp structure prepared in this example, and the measured mechanical nonlinear region was 138%. The L-polylactic acid-polycaprolactone copolymer micro-nanofiber film with a fiber crimp structure prepared in this example also has a larger mechanical nonlinear region.

Embodiment 3

[0058] The content of embodiment 3 is basically the same as embodiment 1, and its difference is:

[0059] In step (2): the micro-nanofiber film prepared in step (1) is stretched once along the fiber orientation direction, and the stretching ratio is 140%.

[0060] The method described in this example can be used to prepare a micro-nano fiber film of L-polylactic acid-polycaprolactone copolymer with a stable fiber crimp structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com