Production method of continuous polymerization melt direct spinning functional polyamide fiber and the functional polyamide fiber

A technology of polyamide fiber and production method, which is applied in the field of polymer material synthesis, can solve the problems of difficult to achieve high uniform dispersion of functional powder, poor spinning performance of functional polyamide melt, etc., and achieves large-scale industrialized continuous production, The effect of easy industrialization and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

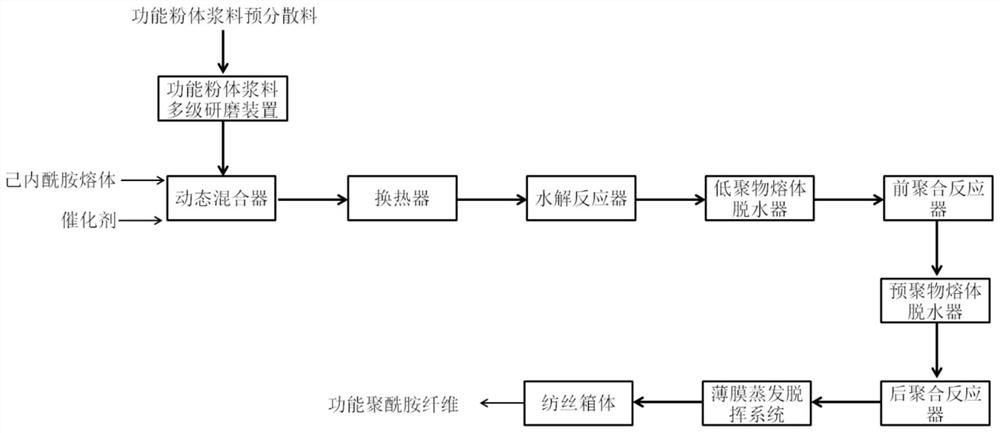

Method used

Image

Examples

Embodiment 1

[0055] (1) The functional powder slurry pre-dispersion made of water, caprolactam and pigment blue 15:3 is continuously transported to the functional powder slurry multi-stage grinding device for grinding and dispersion, in which water, caprolactam and pigment blue 15:3 The mass ratio of the functional powder slurry is 1:0.8:1.8, and the functional powder slurry multi-stage grinding device is composed of 3 grinding machines connected in series to obtain a functional powder with a pigment blue 15:3 content of 50wt% and an average particle size of 0.28μm slurry;

[0056] (2) Mix the functional powder slurry prepared in step (1) with the caprolactam melt and the catalyst through a dynamic mixer, adjust the temperature with a heat exchanger, and then enter the hydrolysis reactor for ring-opening reaction, wherein the catalyst is phosphoric acid, catalyst The addition amount is 400ppm of the mass of the caprolactam melt, the addition amount of the functional powder slurry is 5% of ...

Embodiment 2

[0063] (1) Continuously convey the functional powder slurry pre-dispersion prepared by water, caprolactam and carbon black to the functional powder slurry multi-stage grinding device for grinding and dispersion, wherein the mass ratio of water, caprolactam and carbon black is 1: 0.8:0.77, the functional powder slurry multi-stage grinding device is composed of three grinding machines connected in series to obtain a functional powder slurry with a carbon black content of 30wt% and an average particle size of 0.11 μm;

[0064] (2) Mix the functional powder slurry prepared in step (1) with the caprolactam melt and the catalyst through a dynamic mixer, adjust the temperature with a heat exchanger, and then enter the hydrolysis reactor for ring-opening reaction, wherein the catalyst is phosphoric acid, catalyst The addition amount is 400ppm of the mass of the caprolactam melt, the addition amount of the functional powder slurry is 10.7% of the mass of the caprolactam melt, the temper...

Embodiment 3

[0071] (1) The functional powder slurry pre-dispersion prepared by water, caprolactam and pigment red 179 is continuously transported to the functional powder slurry multi-stage grinding device for grinding and dispersion, wherein the mass ratio of water, caprolactam and pigment red 179 is 1:0.5:0.375, the functional powder slurry multi-stage grinding device is composed of two grinding machines connected in series to obtain a functional powder slurry with a pigment red 179 content of 20wt% and an average particle size of 0.28 μm;

[0072] (2) The functional powder slurry prepared in step (1) is mixed with the caprolactam melt and the catalyst through a dynamic mixer, and the temperature is adjusted by a heat exchanger, and then enters a hydrolysis reactor for ring-opening reaction, wherein the catalyst is metaphosphoric acid, catalyst The addition amount of the caprolactam melt is 1000ppm, the addition amount of the functional powder slurry is 9.4% of the caprolactam melt mass,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com