Amination hexagonal boron nitride as well as preparation method and application thereof

A technology of hexagonal boron nitride and amination, which is applied in chemical instruments and methods, dyeing low-molecular organic compound treatment, fibrous fillers, etc., can solve problems such as poor dispersion effect, poor storage stability, and restrictions on the application of boron nitride. Achieve the effects of simple handling, enhanced tensile strength, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

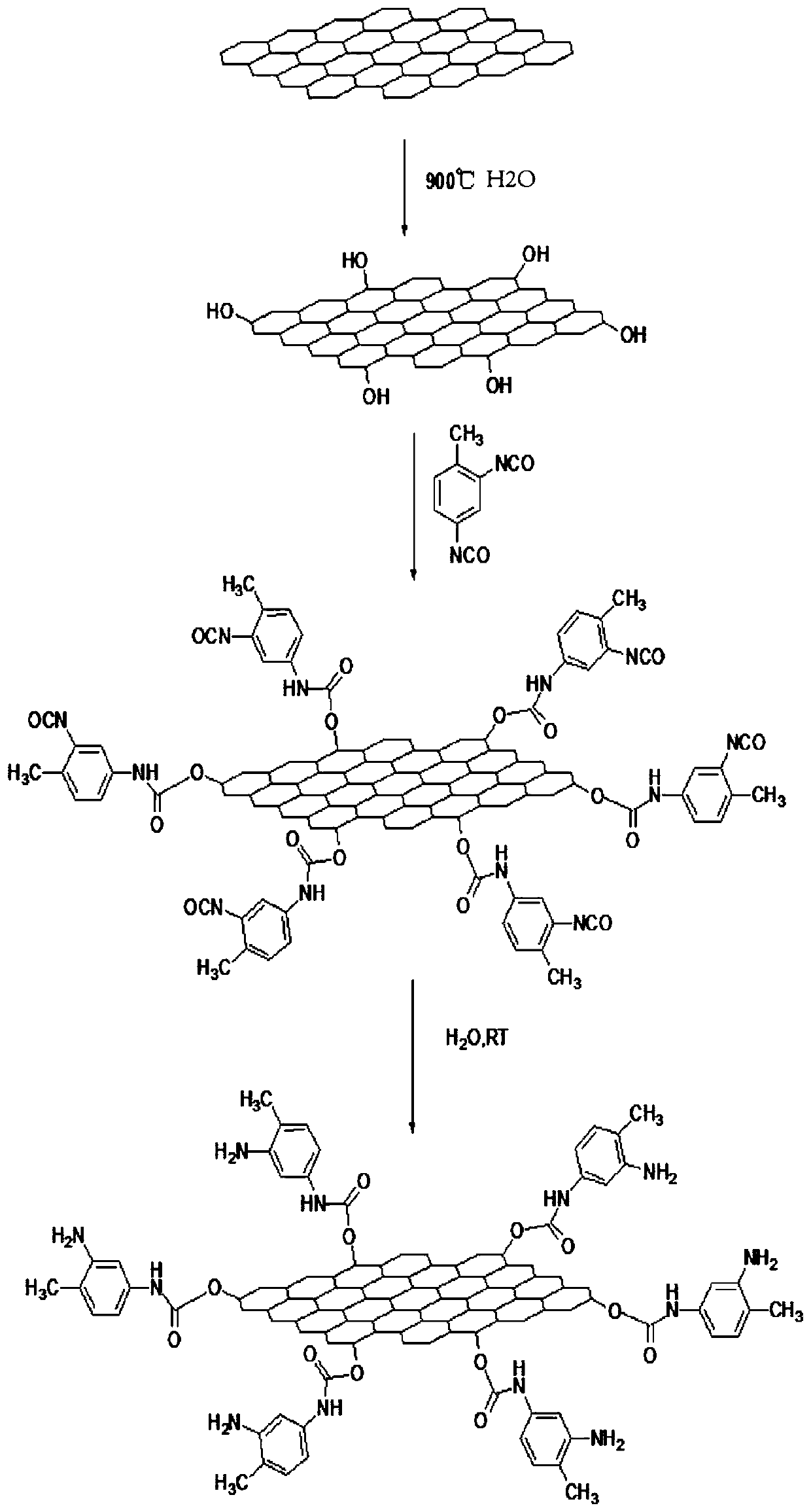

[0032] Embodiment 1: Preparation of aminated hexagonal boron nitride

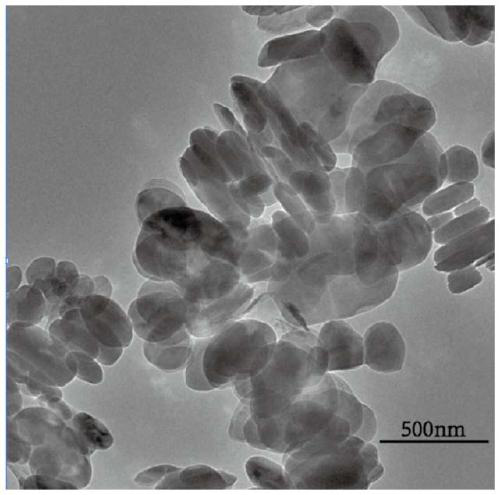

[0033] 1) Take 2g of Aladdin Reagent Company’s hexagonal boron nitride powder with a specification of 1-2 μm and place it in a porcelain boat, put it into a tube furnace, vacuumize it, fill it with argon gas for protection, and place a container full of it in the upwind direction. The porcelain boat of ionized water is used to provide a water vapor atmosphere, heated to 900 ° C, kept for 3 hours, and cooled to room temperature to obtain preliminary hydroxylated boron nitride powder;

[0034] Disperse the powder obtained above in water and ultrasonically treat it for 5 minutes, then centrifuge at a speed of 1000-1200 rpm for 30 minutes to remove large particles and obtain a suspension;

[0035] drying the centrifuged upper three-quarters of the suspension at 60-80°C to remove water for further drying, and freeze-drying in a freeze dryer at a low temperature to obtain hydroxylated modified boron nitride powde...

Embodiment 2

[0038] Embodiment 2: Preparation of aminated hexagonal boron nitride

[0039] 1) Take 2g of Aladdin Reagent Company’s hexagonal boron nitride powder with a specification of 1-2 μm and place it in a porcelain boat, put it into a tube furnace, vacuumize it, fill it with argon gas for protection, and place a container full of it in the upwind direction. The porcelain boat of ionized water is used to provide a water vapor atmosphere, heated to 950 ° C, kept for 2.5 hours, cooled to room temperature, and obtained preliminary hydroxylated boron nitride powder;

[0040] Disperse the powder obtained above in water and ultrasonically treat it for 5 minutes, then centrifuge at a speed of 1000-1200 rpm for 30 minutes to remove large particles and obtain a suspension;

[0041] drying the centrifuged upper three-quarters of the suspension at 60-80°C to remove water for further drying, and freeze-drying in a freeze dryer at a low temperature to obtain hydroxylated modified boron nitride pow...

Embodiment 3

[0044] Embodiment 3: Preparation of aminated hexagonal boron nitride

[0045] 1) Take 2g of Aladdin Reagent Company’s hexagonal boron nitride powder with a specification of 1-2 μm and place it in a porcelain boat, put it into a tube furnace, vacuumize it, fill it with argon gas for protection, and place a container full of it in the upwind direction. The porcelain boat of ionized water is used to provide a water vapor atmosphere, heated to 1000 ° C, kept for 2 hours, cooled to room temperature, and obtained preliminary hydroxylated boron nitride powder;

[0046] Disperse the powder obtained above in water and ultrasonically treat it for 5 minutes, then centrifuge at a speed of 1000-1200 rpm for 30 minutes to remove large particles and obtain a suspension;

[0047] drying the centrifuged upper three-quarters of the suspension at 60-80°C to remove water for further drying, and freeze-drying in a freeze dryer at a low temperature to obtain hydroxylated modified boron nitride powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com