Electrolyzed water hydrogen production catalyst and preparation method thereof

A catalyst and water hydrogen production technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrolysis process, etc., can solve a large number of environmental pollution problems, achieve advanced technology, high product yield, detailed and accurate data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

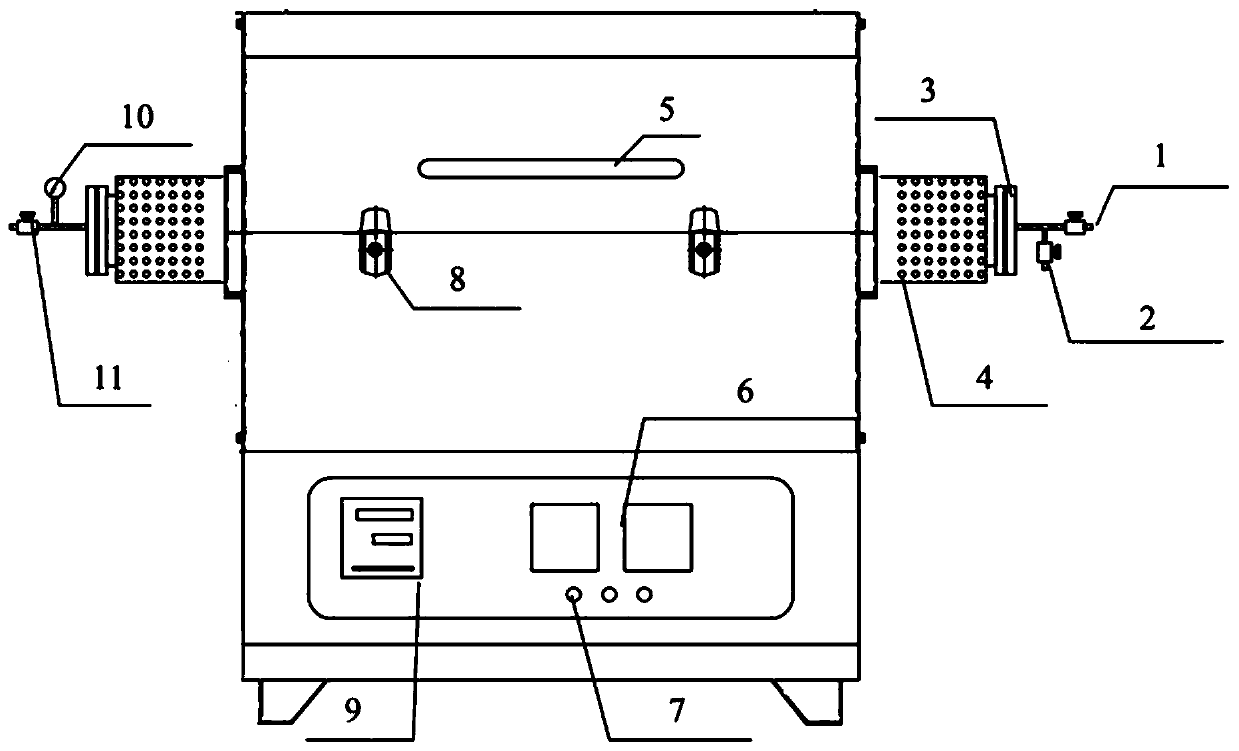

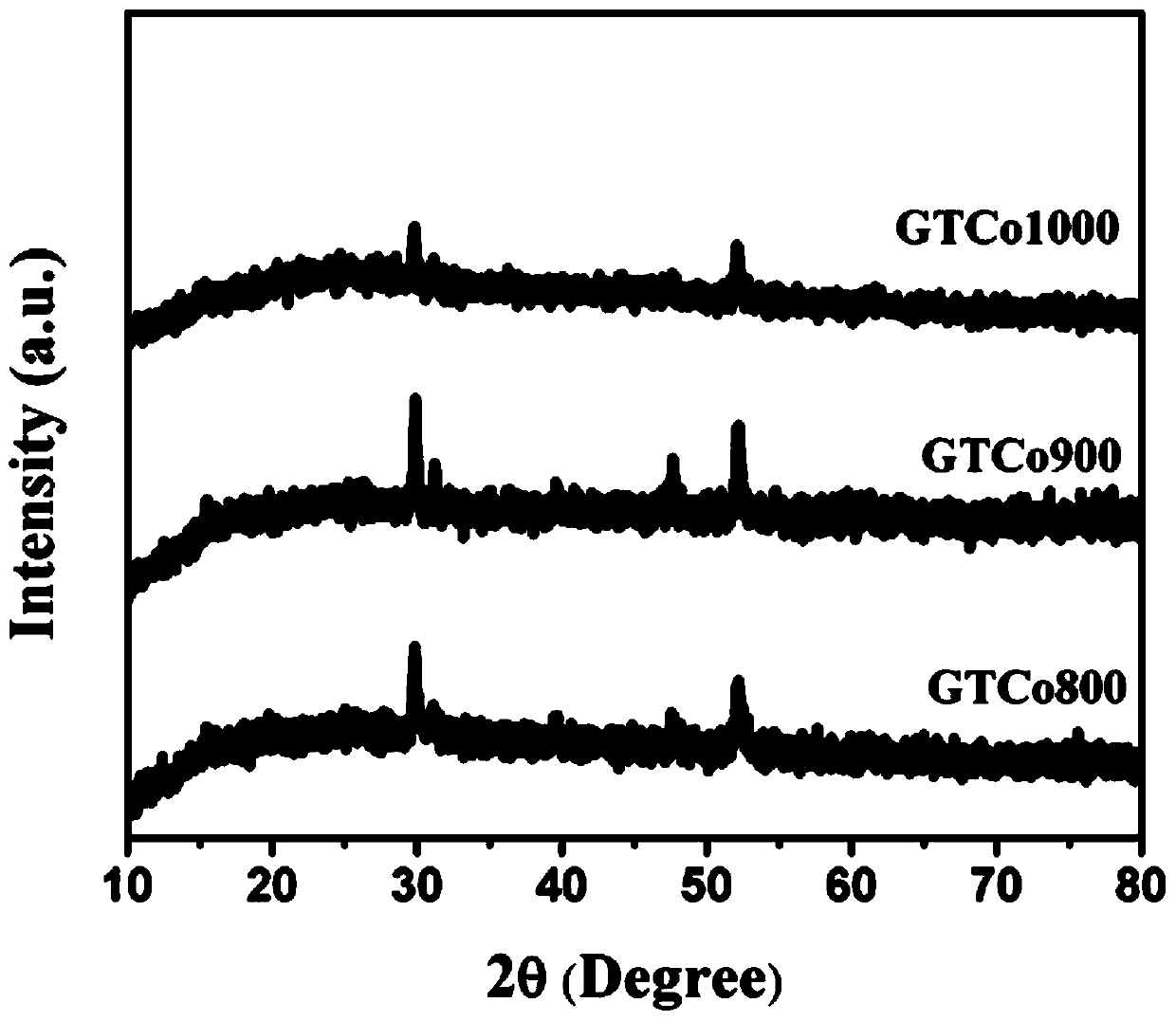

[0040] figure 1 and figure 2 As shown in the figure, it is a state diagram of the synthesis and preparation of the hydrogen production catalyst for electrolysis of water.

[0041] Quantities of the chemical substances used in the preparation are determined according to a preset range, with grams and milliliters as measurement units.

[0042] The synthesis of electrolyzed water hydrogen production catalyst is carried out in agate grinding and tube furnace, which is completed by room temperature grinding process and high temperature calcination under inert atmosphere;

[0043] figure 1 As shown, the reaction precursors (cobalt chloride, thiourea and glucose) were added to the agate mortar and manually ground for 30 min.

[0044] figure 2 As shown, the high-temperature calcination is carried out in a tube, using nitrogen as a protective gas, and the calcination temperature is 800-1000°C. figure 2 The medium carbonization device includes: air inlet 1, vacuum port 2, flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com