Preparation method and application of polycarbonate-based polymer electrolyte

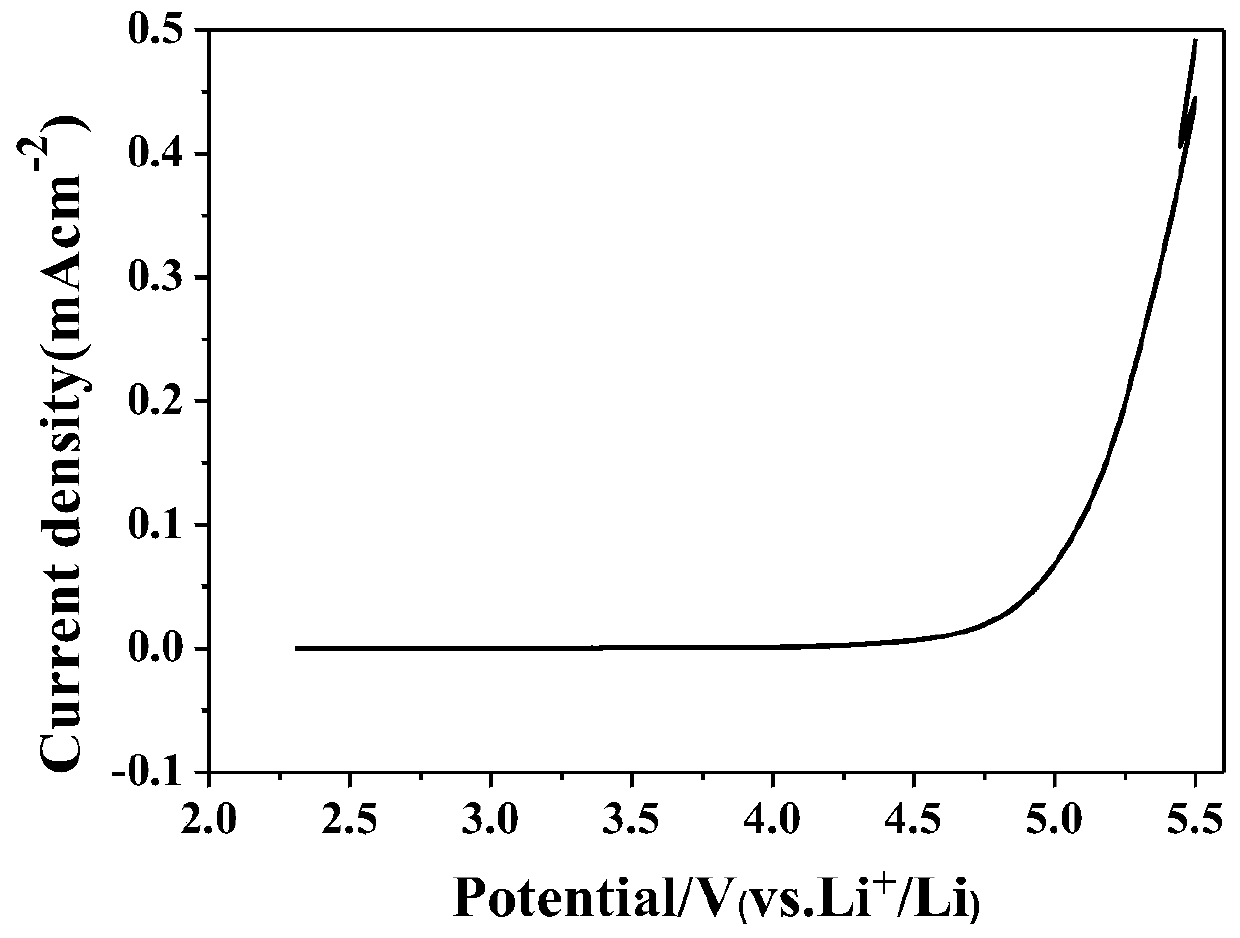

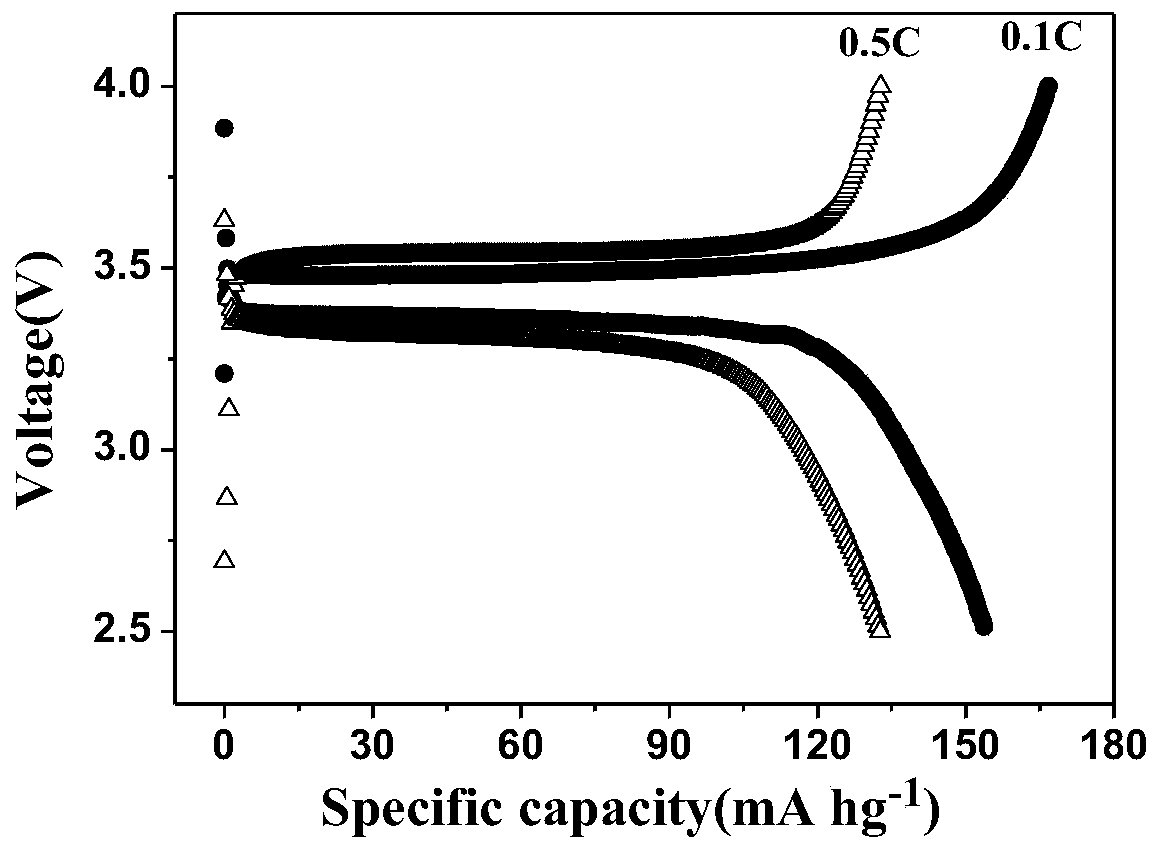

A polycarbonate and polymer technology, used in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of low electrochemical window and unsuitable high-nickel cathode material system, so as to eliminate environmental pollution and improve long-term performance. Cyclic stability performance, damage suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

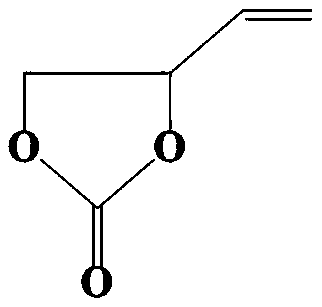

Embodiment 1

[0029] Dissolve 3 g of ethylene carbonate and 0.8 g of lithium bistrifluoromethanesulfonimide (LiTFSI) in 5 ml of acetonitrile, stir at room temperature to dissolve completely; add 0.1 g of azobisisobutyronitrile and stir evenly. On the polytetrafluoroethylene mold, using whatman membrane as a porous support framework, scrape-coat the evenly stirred mixture on both sides of whatman membrane; heat at 80°C for 10 hours in a vacuum oven to solidify to form a film.

Embodiment 2

[0031] Dissolve 1g of ethylene carbonate and 0.25g of lithium bistrifluoromethanesulfonylimide (LiTFSI) into 1.5ml of N-methylpyrrolidone (NMP), stir at room temperature to dissolve completely; add 0.02g of azobis Isobutyronitrile was stirred evenly. On the polytetrafluoroethylene mold, using whatman membrane as a porous support framework, scrape-coat the evenly stirred mixture on both sides of whatman membrane; heat at 80°C for 10 hours in a vacuum oven to solidify to form a film.

Embodiment 3

[0033] Dissolve 1.38g of ethylene carbonate and 0.4g of lithium bistrifluoromethanesulfonylimide (LiTFSI) into 1.5ml of N-methylpyrrolidone (NMP), stir at room temperature to dissolve completely; add 0.02g of bis( acetylacetonate) dibutyltin and stir evenly. On the polytetrafluoroethylene mold, using whatman membrane as a porous support framework, scrape-coat the evenly stirred mixture on both sides of whatman membrane; heat at 80°C for 10 hours in a vacuum oven to solidify to form a film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com