natao 3 Method for preparing perovskite solar cells as electron transport layer

A technology of electron transport layer and solar cell, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems that limit the efficiency and stability of perovskite solar cells, and achieve novel preparation methods and simple and convenient manufacturing processes , The effect of stable device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

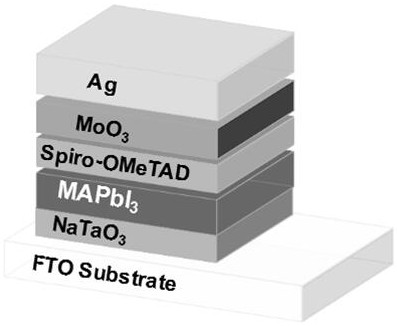

[0026] NaTaO 3 A method for preparing a perovskite solar cell as an electron transport layer, comprising the following steps:

[0027] (1) FTO transparent conductive glass substrate cleaning and NaTaO 3 Film preparation: The FTO transparent conductive glass substrate was ultrasonically cleaned three times with deionized water, acetone, and ethanol, and then dried at 100°C until the solvent and moisture were completely removed. The treated FTO transparent conductive glass substrate was treated with a UV lamp Treat with ozone for 25 min, disperse 10 mg of NaTaO3 in 1 mL of deionized water for later use, and then spin-coat the treated FTO transparent conductive glass substrate with NaTaO 3 , put it on a heating platform and heat at 100°C for 30min, with a thickness of 70 nm.

[0028] (2) Preparation of perovskite film: Dissolve 180mg methylammonium iodide and 553mg lead iodide in 1mL mixed solution of dimethyl sulfoxide and γ-butyrolactone, dimethyl sulfoxide and γ-butyrolacton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com