420MPa-level low-alloy high-intensity ultra-thick steel plate and manufacturing method thereof

A low-alloy high-strength, extra-thick steel plate technology, applied in the field of extra-thick steel plate preparation, can solve the problems of inability to produce thick extra-thick plates, inability to organize mass production, low production efficiency, etc., to eliminate macroscopic and microscopic defects, The effect of mitigating macroscopic and microscopic defects and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

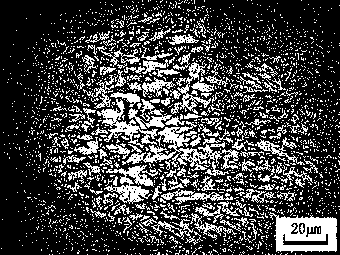

Image

Examples

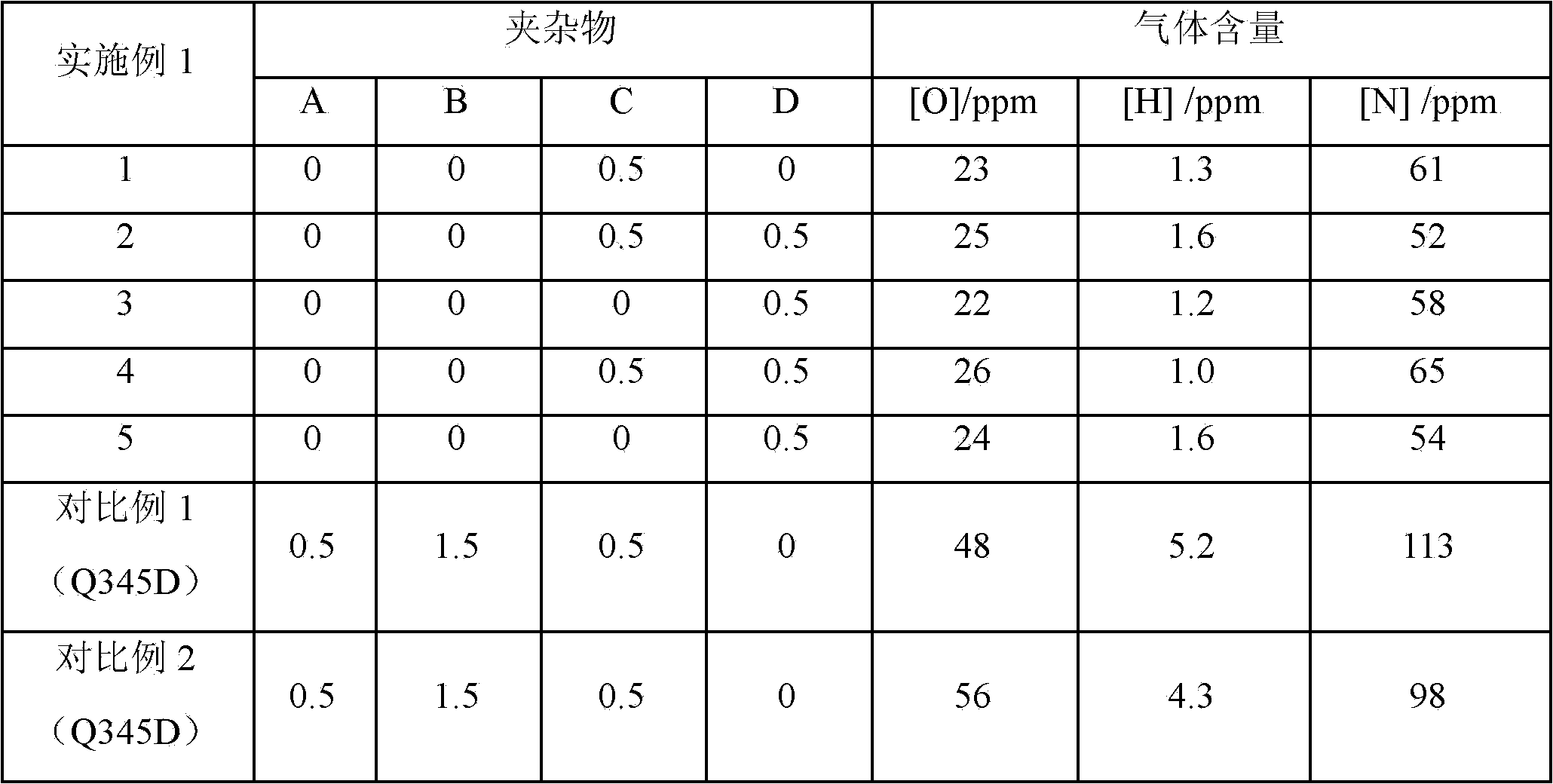

Embodiment 1

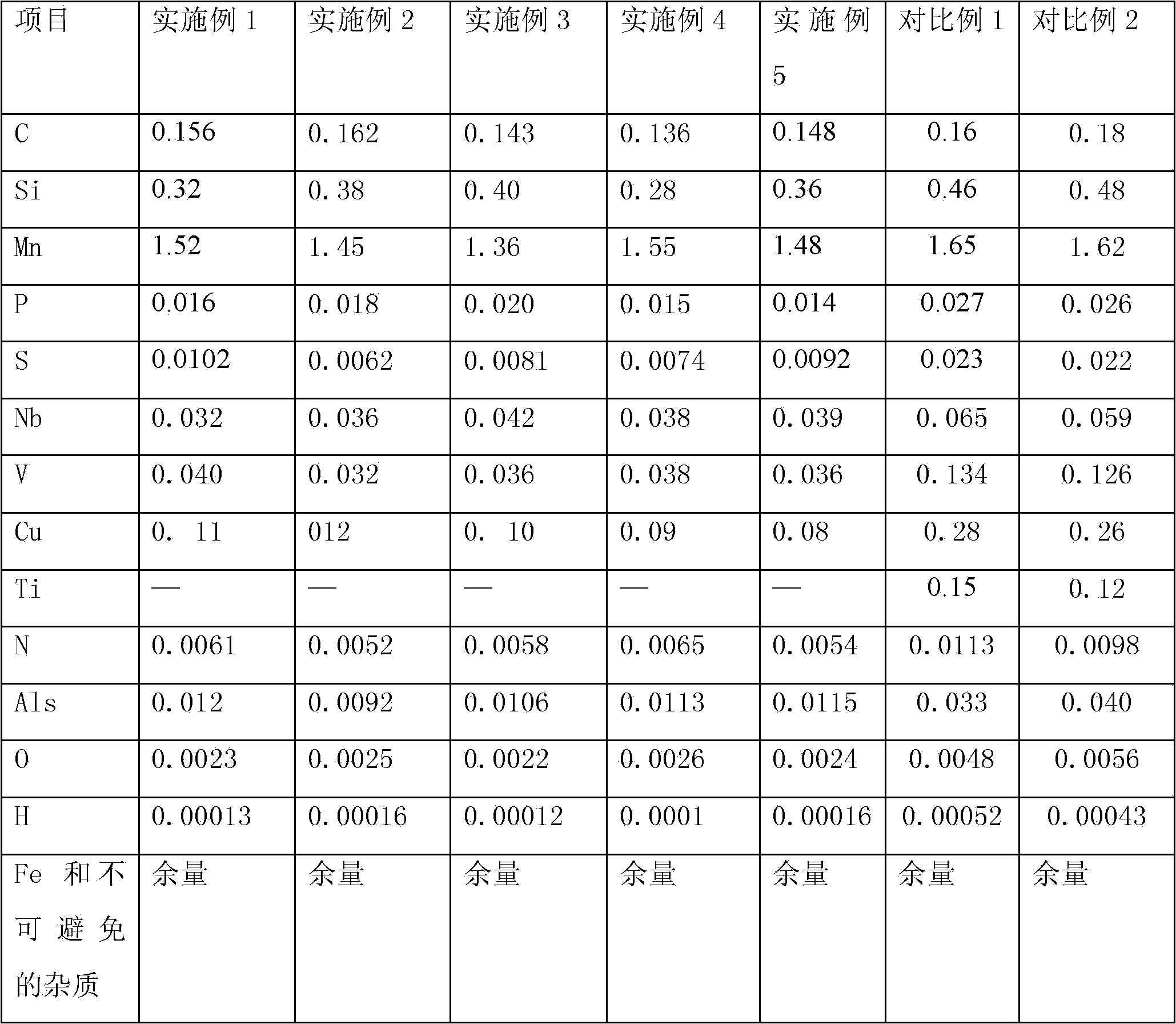

[0038]A 420MPa low-alloy high-strength steel plate with a thickness of 160mm, its chemical composition and mass percentage content are shown in Table 1, specifically: C: 0.156%, Si: 0.32%, Mn: 1.52%, P: 0.016%, S: 0.0102 %, Nb: 0.032%, V: 0.040%, Cu: 0.11%, N: 0.0061%, Als: 0.012%, O: 0.0023%, H: 0.00013%, and the balance is Fe and unavoidable impurities. The specific preparation method is as follows:

[0039] (1) According to the predetermined composition, it is smelted in an electric arc furnace, and then refined in a ladle refining furnace. In the ladle refining furnace (LF furnace) treatment, active lime is added to 40Kg / ton of steel for desulfurization and dephosphorization. Calcium silicon powder is added per ton of steel for deoxidation and alloying treatment; then it is treated in a vacuum furnace. The vacuum furnace treatment is as follows: blowing argon gas at 80ml / min, and controlling the vacuum degree to not exceed 67Pa, keeping the vacuum treatment not less than ...

Embodiment 2-4

[0046] With reference to the method of Example 1, each 420MPa level low-alloy high-strength 160mm thick steel plate was prepared according to the chemical composition content design and process conditions of the steel plate in Table 1, Table 3, and Table 5, and the mechanical properties prepared thereby are shown in Table 6. . In addition, the comparison of the internal quality of the billets in Examples 2-4 includes inclusions and gas content inside the billets, as shown in Table 2.

Embodiment 5

[0048] A 420MPa level low-alloy high-strength steel plate with a thickness of 100mm, its chemical composition and mass percentage content are shown in Table 1. The specific preparation method is as follows:

[0049] (1) Smelting in an electric arc furnace according to the predetermined composition, and then refining in a ladle refining furnace. In the ladle refining furnace, active lime is added to 60Kg / ton of steel for desulfurization and dephosphorization, and silicon is added to 0.04Kg / ton of steel. Calcium powder is subjected to deoxidation and alloying treatment; then processed in a vacuum furnace, the vacuum furnace treatment is as follows: according to 100ml / min, argon gas is blown in, and the vacuum degree is controlled to be no more than 67Pa, and the vacuum treatment is kept for no less than 25 minutes; finally The casting speed is controlled at 1.6 to 1.7 m / min for continuous casting to obtain a continuous casting billet of 150mm (thickness) × 150mm (width) × 4500mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com